Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Insulation Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Insulation Technician so you can tailor your answers to impress potential employers.

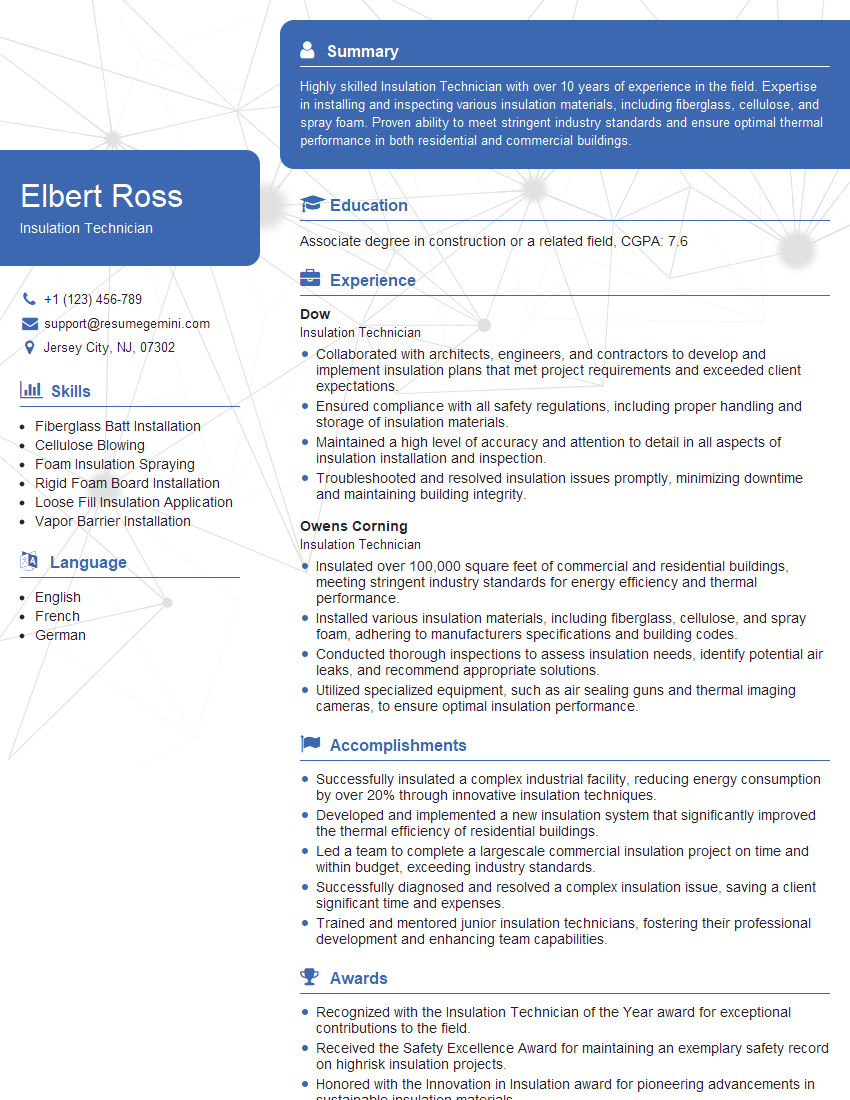

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Technician

1. Describe the different types of insulation materials and their applications in various construction projects?

Insulation materials come in a wide range, each with unique properties and applications. Here are the most common types:

- Fiberglass insulation: Affordable and widely used, it’s made of glass fibers and provides good thermal resistance.

- Cellulose insulation: Made from recycled paper, it’s eco-friendly and offers excellent soundproofing.

- Spray foam insulation: A two-part polyurethane foam that expands and fills cavities, providing excellent air sealing and insulation.

- Mineral wool insulation: Made from volcanic rock or slag, it’s fire-resistant and has high noise reduction properties.

- Rigid foam insulation: Available in sheets or boards, it has a high R-value and is often used for exterior walls and roofs.

2. Explain the importance of air sealing in insulation installation?

Minimizing Air Infiltration

- Air sealing prevents warm or cold air from leaking in or out of the building, improving energy efficiency.

Moisture Control

- Air sealing reduces moisture infiltration, preventing condensation and mold growth within the insulation.

Better Insulation Performance

- Air leaks can significantly reduce the effectiveness of insulation. Air sealing ensures the insulation performs at its optimal level.

3. Describe the steps involved in installing insulation in a residential attic?

Insulating an attic requires careful steps to ensure proper installation:

- Inspection: Assess the attic’s condition, including ventilation and access.

- Air sealing: Seal gaps around light fixtures, pipes, and vents using caulk or expanding foam.

- Insulation placement: Unroll and lay insulation batts or blankets between joists, ensuring they fit snugly.

- Vapor barrier: Install a vapor barrier on the warm side of the insulation to prevent moisture penetration.

- Additional insulation: Add additional layers of insulation perpendicular to the first layer to increase R-value.

4. How do you determine the appropriate R-value for insulation in a specific climate?

The appropriate R-value depends on a combination of factors, including:

- Climate zone: Different climate zones have varying heating and cooling requirements, influencing the necessary R-value.

- Building type: Residential, commercial, and industrial buildings have different insulation needs.

- Building orientation: The direction the building faces can affect its exposure to sunlight and heat gain.

- Energy efficiency goals: Higher R-values result in greater energy efficiency and lower utility costs.

5. What are the potential hazards associated with handling and installing insulation materials?

- Inhalation: Insulation fibers can irritate the lungs and respiratory system if inhaled.

- Skin irritation: Fiberglass and mineral wool insulation can cause itching and rashes on exposed skin.

- Eye irritation: Insulation particles can irritate the eyes, causing redness and discomfort.

- Fire hazard: Some insulation materials, such as cellulose, can be flammable and require proper handling and storage.

6. Describe the techniques used to test the effectiveness of insulation in a building?

- Infrared camera: Detects temperature differences and identifies areas with inadequate insulation.

- Blower door test: Measures air leakage in a building, revealing air gaps that can reduce insulation effectiveness.

- Thermal imaging: Provides visual representation of heat loss and helps identify areas with poor insulation.

- Energy audit: Assesses the overall energy efficiency of a building, including the effectiveness of insulation.

7. Explain the different methods used to install spray foam insulation and their pros and cons?

Open Cell Spray Foam

- Pros: Flexible, fills cavities well, provides good soundproofing.

- Cons: Lower R-value compared to closed cell foam, more expensive.

Closed Cell Spray Foam

- Pros: Higher R-value, provides excellent air sealing, moisture resistant.

- Cons: More rigid, can be difficult to remove, can release harmful gases if not installed properly.

8. What are the best practices for maintaining and inspecting insulation over time?

- Regular inspections: Check insulation for damage, moisture, or settling.

- Air sealing maintenance: Inspect and repair air seals to prevent air leakage.

- Moisture control: Address any moisture issues that can compromise insulation performance.

- Pest control: Prevent pests from nesting in insulation, which can damage it.

- Professional cleaning: If necessary, hire a professional to clean insulation and remove contaminants.

9. Explain the principles behind selecting the correct type of insulation for a commercial building?

Insulation selection for commercial buildings involves several key factors:

- Energy efficiency goals: Determine the desired level of energy savings and select insulation with appropriate R-values.

- Building construction: Consider the type of building, its envelope, and the insulation’s compatibility.

- Fire safety: Choose insulation materials that meet fire resistance requirements for commercial buildings.

- Acoustical performance: Evaluate the need for soundproofing and select insulation with appropriate sound absorption properties.

- Sustainability: Consider the environmental impact of insulation materials and opt for eco-friendly options.

10. Discuss the latest advancements and trends in insulation materials and techniques?

- Vacuum Insulation Panels (VIPs): Ultrathin insulation with exceptional R-values for limited space applications.

- Aerogel Insulation: Lightweight and highly effective insulation made from a silica-based gel.

- Phase Change Materials (PCMs): Insulation that absorbs and releases heat, providing thermal comfort.

- Smart Insulation: Insulation with sensors and controls that adjust to changing conditions, optimizing energy efficiency.

- Sustainability Focus: Increased use of eco-friendly and recycled materials in insulation production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Technicians are responsible for installing and maintaining insulation in buildings, and to help reduce heat loss and improve energy efficiency. Insulation helps regulate the temperature of a building, making it more comfortable and reducing the cost of heating and cooling. Key responsibilities include:

1. Insulation Installation

Insulation Technicians follow blueprints and specifications to determine the type and amount of insulation required for a particular project.

- Install insulation in attics, walls, floors, and ceilings using a variety of techniques, such as spraying, blowing, or rolling.

- Seal gaps and cracks around windows, doors, and other openings to prevent air leaks.

2. Insulation Repair

Insulation Technicians repair damaged or deteriorated insulation, which can occur due to water damage, pests, or other factors.

- Inspect insulation for damage and identify areas that need to be repaired.

- Replace damaged insulation with new insulation of the same type and thickness.

3. Insulation Removal

Insulation Technicians remove old or damaged insulation during renovations or repairs.

- Remove insulation safely and dispose of it properly.

- Clean the area where the insulation was removed and prepare it for new insulation.

4. Safety and Regulations

Insulation Technicians must adhere to safety regulations and follow industry standards to ensure the proper installation and maintenance of insulation.

- Wear appropriate personal protective equipment (PPE), such as respirators, gloves, and safety glasses.

- Handle and store insulation materials safely, following manufacturer’s instructions.

Interview Tips

Preparing for an interview for an Insulation Technician position can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and the responsibilities of the role.

- Visit the company’s website to learn about their products, services, and recent news.

- Read online reviews and articles about the company to get insights into its culture and work environment.

- Identify specific examples from your experience that demonstrate your skills and qualifications for the position.

2. Practice Your Answers

Once you have a good understanding of the company, practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare for questions about your experience, skills, and qualifications.

- Develop clear and concise answers that highlight your strengths and how you can contribute to the company.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This doesn’t mean you have to wear a suit and tie, but your clothing should be clean, pressed, and appropriate for the office environment.

4. Be Punctual

Punctuality shows respect for the interviewer’s time. Plan your route ahead of time and allow extra time for unexpected delays.

5. Follow Up

After the interview, send a thank-you note to the interviewer. Thank them for their time and reiterate your interest in the position. You can also use this opportunity to clarify any information or address any questions that may have come up during the interview.

Next Step:

Now that you’re armed with the knowledge of Insulation Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Insulation Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini