Are you gearing up for an interview for a Insulation Worker Furnace Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Insulation Worker Furnace Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

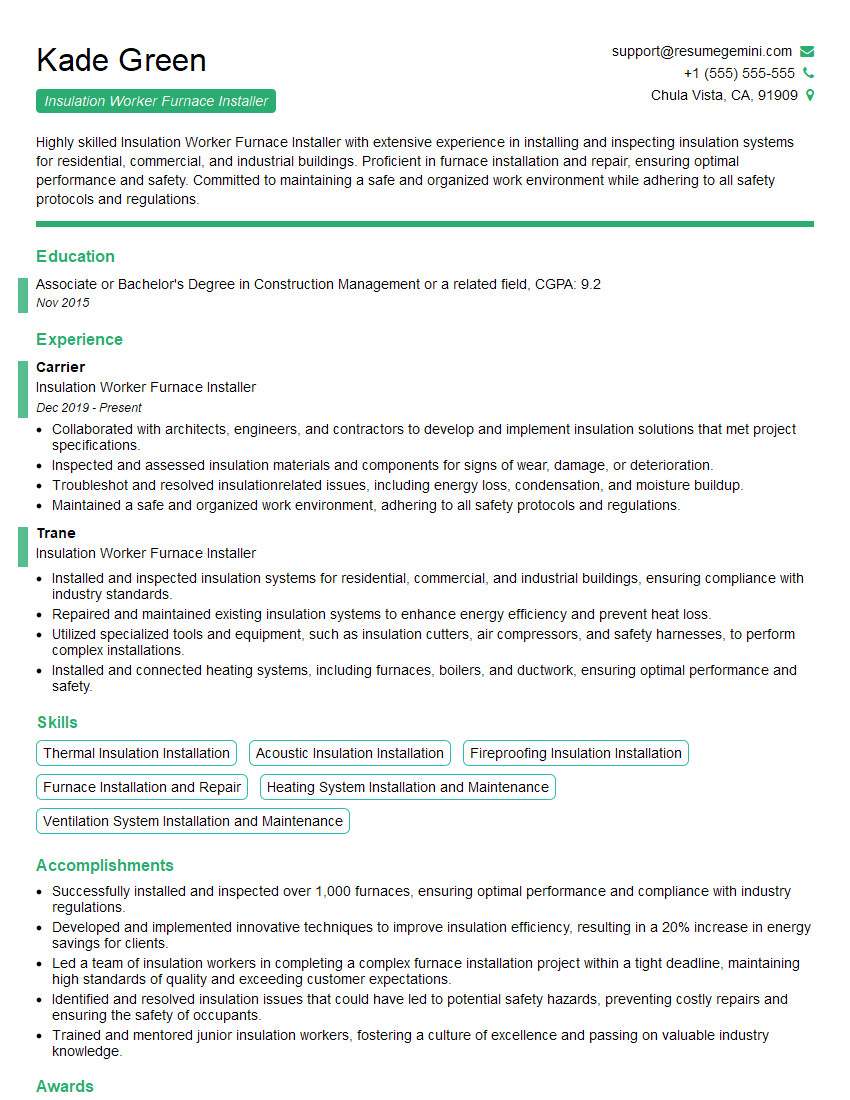

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Worker Furnace Installer

1. What are the different types of insulation materials used for furnaces and their properties?

The different types of insulation materials used for furnaces and their properties are:

- Fiberglass: Fiberglass is a type of glass wool that is made from fine fibers of glass. It is a lightweight and inexpensive material that is effective at insulating against heat and cold. It is not flammable and does not absorb moisture.

- Mineral Wool: Is a type of insulation that is made from natural minerals, such as rock or slag. It is a fire-resistant material that does not absorb moisture. It is more expensive than fiberglass, but considered more durable.

- Cellulose: Cellulose is a type of insulation that is made from recycled paper. It is a lightweight and inexpensive material that is effective at insulating against heat and cold. It is not fire-resistant and absorbs moisture.

- Polystyrene: Is a type of plastic foam that is used as insulation. It is a lightweight and inexpensive material that is effective at insulating against heat and cold. It is not fire-resistant and does not absorb moisture.

- Polyurethane: Is a type of plastic foam that is used as insulation. It is a lightweight and inexpensive material that is effective at insulating against heat and cold. It is fire-resistant and does not absorb moisture.

2. What are the steps involved in installing insulation in a furnace?

The steps involved in installing insulation in a furnace are:

- Prepare the furnace: Before installing insulation, the furnace should be cleaned and any debris or dirt removed. Ensure that the furnace is turned off and all power sources are disconnected.

- Measure the furnace: Measure the furnace to determine the amount of insulation needed. Determine all areas that require insulation.

- Cut the insulation: Cut the insulation to the appropriate size and shape to fit the furnace. Carefully handle the insulation to avoid damage.

- Position the insulation: Position the insulation in the furnace, ensuring that all areas are covered and there are no gaps.

- Secure the insulation: Secure the insulation with tape or wire to prevent it from moving or falling out.

3. What safety precautions should be taken when working with insulation?

When working with insulation, it is vital to take the following safety precautions:

- Wear protective clothing: Gloves, a mask, and eye protection should be worn when handling insulation to prevent the skin, eyes, or lungs from getting irritated.

- Ventilate the area: Ensure that the area where insulation is being installed is well-ventilated to prevent the buildup of dust and fumes.

- Avoid inhaling dust: Do not inhale dust created by insulation, as it can cause respiratory problems.

- Keep insulation away from open flames: Insulation can be flammable, so keep it away from open flames or sparks.

- Store insulation properly: Store insulation in a dry and cool place to prevent damage or deterioration.

4. What are the common problems that can occur with furnace insulation and how do you troubleshoot them?

Common problems that can occur with furnace insulation and how to troubleshoot them are:

- Air leaks: Air leaks can occur around the edges of the insulation or through holes in the insulation. Check for any gaps or holes and seal them with caulk or expanding foam.

- Moisture: Moisture can cause insulation to lose its effectiveness. Check for any sources of moisture, such as leaks or condensation, and address them.

- Settling: Over time, insulation can settle and become less effective. Check the insulation regularly and add more if necessary.

5. What tools and equipment are used for installing furnace insulation?

The tools and equipment used for installing furnace insulation typically include:

- Measuring tape

- Utility knife

- Scissors

- Staple gun

- Insulation installer

- Caulk gun

- Gloves

- Mask

- Eye protection

6. How do you calculate the R-value of insulation?

The R-value of insulation is a measure of its thermal resistance. To calculate the R-value, divide the thickness of the insulation in inches by its thermal conductivity in BTU-in/hr-ft2-°F. The higher the R-value, the better the insulation.

7. What are the energy-saving benefits of insulating a furnace?

Insulating a furnace can significantly lower energy consumption and expenses. Proper insulation helps trap heat within the furnace, reducing the amount of energy required to maintain the desired temperature. This results in lower energy bills and a more efficient heating system.

8. How do you ensure the proper fit and coverage of insulation in a furnace?

To ensure the proper fit and coverage of insulation in a furnace, follow these steps:

- Measure the furnace and cut the insulation to the exact dimensions.

- Position the insulation snugly around the furnace, ensuring there are no gaps or holes.

- Secure the insulation with tape, wire, or staples to prevent shifting or movement.

- Check for any uninsulated areas and add insulation where necessary.

9. What are the maintenance requirements for furnace insulation?

Furnace insulation requires regular maintenance to ensure its effectiveness and longevity. Perform the following maintenance tasks:

- Inspect the insulation annually for any damage, wear, or deterioration.

- Clean or replace the insulation if it becomes dirty, wet, or damaged.

- Check for any air leaks around the insulation and seal them promptly.

- Re-install insulation if it has shifted or moved out of place.

10. How do you stay up-to-date with the latest advancements in furnace insulation materials and techniques?

To stay up-to-date with the latest advancements in furnace insulation materials and techniques, I engage in the following practices:

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Conduct research and explore online resources.

- Participate in continuing education programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Worker Furnace Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Worker Furnace Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Worker Furnace Installers play a crucial role in maintaining and repairing heating systems in residential, commercial, and industrial buildings. Their key responsibilities include:

1. Furnace Installation and Repair

Install, repair, and replace furnaces, including gas, electric, and oil-fired models

- Diagnose and troubleshoot furnace malfunctions

- Replace faulty components, such as burners, fans, and thermostats

2. Insulation Installation and Maintenance

Install and maintain insulation around furnaces, ducts, and other heating components

- Inspect existing insulation for damage or deterioration

- Install new insulation to improve energy efficiency and reduce noise

3. Safety and Compliance

Ensure compliance with building codes, safety regulations, and industry standards

- Test furnaces for leaks and proper operation

- Obtain necessary permits and inspections

4. Communication and Collaboration

Communicate effectively with customers, supervisors, and other tradespeople

- Explain technical information in clear and concise terms

- Collaborate with other contractors on construction or renovation projects

Interview Tips

To ace an interview for an Insulation Worker Furnace Installer position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, services, and culture

- Review the job description thoroughly to understand the specific requirements

- Prepare questions to ask the interviewer about the company and the role

2. Highlight Your Skills and Experience

Emphasize your technical skills, such as furnace repair and insulation installation

- Quantify your experience with specific examples of projects you have worked on

- Explain how your skills and knowledge align with the requirements of the job

3. Demonstrate Safety Awareness

Stress your commitment to safety in the workplace

- Describe your experience with following safety protocols and regulations

- Explain how you identify and mitigate potential hazards

4. Show Willingness to Learn and Grow

Express your interest in expanding your knowledge and skills

- Inquire about opportunities for professional development

- Share examples of how you have proactively pursued training or certification

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Insulation Worker Furnace Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.