Feeling lost in a sea of interview questions? Landed that dream interview for Insulation Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Insulation Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

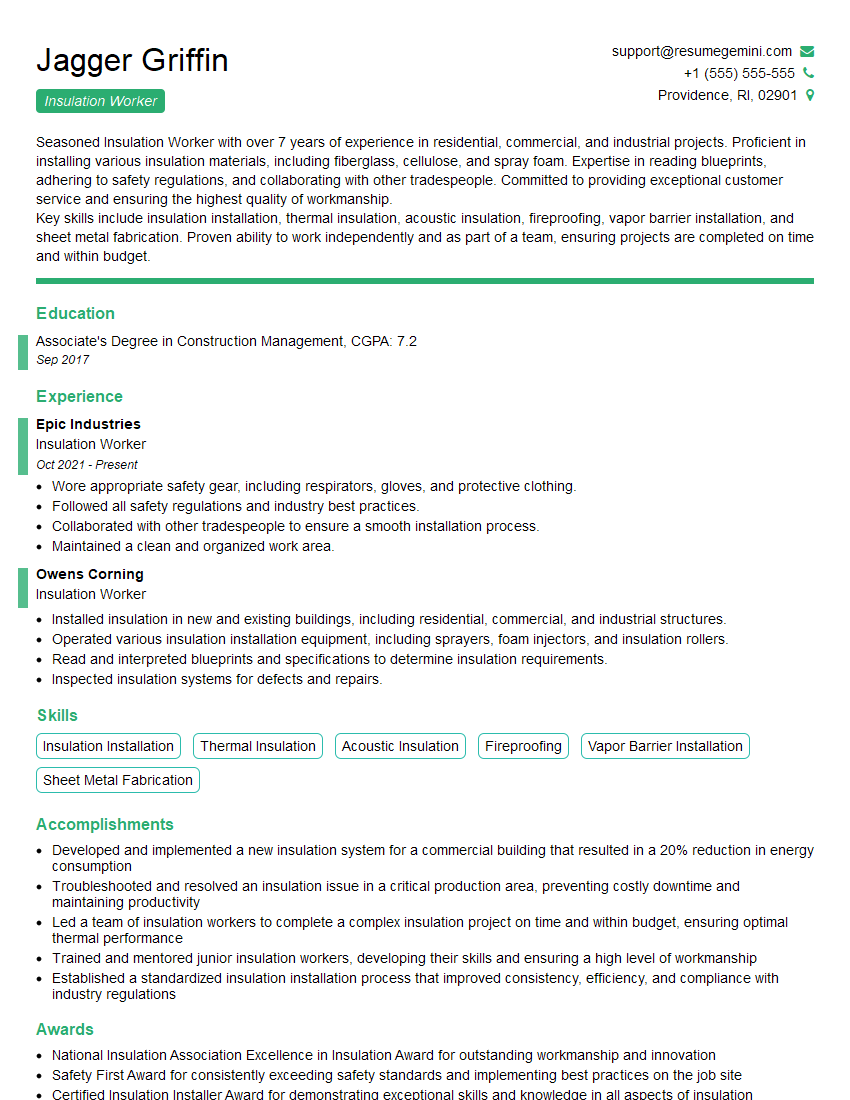

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Worker

1. What are the different types of insulation materials and their applications?

As an Insulation Worker, I am well-versed in the various types of insulation materials and their optimal applications. Here are some of the most commonly used types:

- Fiberglass Insulation: Made of glass fibers, it is cost-effective, fire-resistant, and has excellent thermal and acoustic insulation properties. It is ideal for attics, walls, and floors.

- Cellulose Insulation: Derived from recycled paper fiber, it is an eco-friendly option that provides good thermal and sound insulation. It is suitable for attics, walls, and floors, as well as cellulose spray applications.

- Spray Foam Insulation: A polyurethane or polyisocyanurate-based material that is applied as a liquid and expands to fill cavities. It has high R-value, excellent air sealing properties, and good resistance to moisture and pests.

- Rigid Foam Insulation: Made of polystyrene or polyurethane, it comes in panels or sheets. It has high R-value, is moisture-resistant, and is often used for exterior walls, roofs, and foundations.

- Mineral Wool Insulation: Made from natural or synthetic fibers, it is fire-resistant, provides good sound insulation, and is suitable for various applications, including walls, ceilings, and pipes.

2. What are the key factors to consider when selecting insulation for a specific application?

Insulation Properties:

- R-value: Measure of thermal resistance, indicating the material’s ability to resist heat flow.

- Thermal conductivity: Measures the rate at which heat flows through the material.

- Sound Transmission Class (STC) rating: Indicates the material’s sound absorption and transmission properties.

Application Requirements:

- Location: Indoor or outdoor, attic, walls, floors, etc.

- Space availability: Thickness and density of insulation required.

- Moisture resistance: Exposure to humidity and condensation.

- Fire resistance: Building codes and safety regulations.

Other Factors:

- Cost: Material and installation expenses.

- Environmental impact: Sustainable and eco-friendly options.

- Installation requirements: Specialized equipment or techniques needed.

3. Describe the proper techniques for installing insulation in walls, attics, and ceilings.

Walls:

- Measure and cut insulation batts or rolls to fit the studs.

- Install a vapor barrier to prevent moisture migration.

- Secure insulation with staples, nails, or adhesives.

Attics:

- Lay insulation over the attic floor, ensuring it covers the entire area.

- Seal gaps and penetrations to prevent air leaks.

- Install baffles around vents to ensure proper airflow.

Ceilings:

- Install insulation between ceiling joists.

- Use friction fit or specialized clips to hold insulation in place.

- Seal around fixtures and pipes to minimize air infiltration.

4. How do you ensure a building is properly air-sealed after insulation installation?

- Inspect for Gaps and Cracks: Check around pipes, wires, windows, and doors for openings.

- Use Sealants and Caulking: Apply caulk or sealant to fill gaps and cracks, creating an airtight barrier.

- Install Weatherstripping: Seal moving parts like windows and doors to prevent air leaks.

- Use Expanding Foam: Fill larger gaps or penetrations with expanding foam, which expands to create a tight seal.

- Test for Air Leakage: Use a blower door test or smoke pencil to identify areas where air is leaking and make necessary adjustments.

5. What safety precautions must be taken when working with insulation materials?

- Wear Protective Clothing: Use gloves, masks, and eye protection to prevent contact with insulation fibers.

- Ventilate Work Areas: Ensure adequate ventilation to remove dust and fibers during installation.

- Handle Loose Insulation Carefully: Minimize exposure to airborne fibers by using dust collectors and masks.

- Follow Manufacturer Instructions: Adhere to the manufacturer’s guidelines for handling, storage, and disposal of insulation materials.

- Be Aware of Chemical Hazards: Certain insulation materials may contain chemicals that require specific handling procedures.

6. How do you stay updated with the latest insulation materials and installation techniques?

- Attend Industry Events: Participate in conferences, trade shows, and workshops.

- Read Trade Publications: Stay informed through industry journals, magazines, and online resources.

- Obtain Certifications: Pursue certifications from organizations like the National Insulation Association (NIA) or Building Performance Institute (BPI).

- Consult with Manufacturers: Reach out to manufacturers for technical support, product literature, and training opportunities.

- Network with Professionals: Connect with other insulation workers, contractors, and industry experts to exchange knowledge and best practices.

7. How do you manage and dispose of insulation waste?

- Separate Waste Types: Keep different types of insulation waste, such as fiberglass and cellulose, separate for proper disposal.

- Use Designated Containers: Collect waste in designated containers or bags to prevent contamination.

- Check Regulations: Follow local and state regulations for the disposal of insulation materials, which can vary depending on the type.

- Consider Recycling: Explore options for recycling certain types of insulation, such as cellulose or rigid foam.

- Dispose Responsibly: Ensure proper disposal through approved landfills or waste management facilities.

8. What are the challenges you have faced as an Insulation Worker and how did you overcome them?

One of the challenges I faced was working in tight and confined spaces, especially in attics and crawlspaces. To overcome this, I learned to use proper ergonomics, minimize the use of ladders, and always prioritize safety by wearing protective gear and securing the area properly.

Another challenge was dealing with moisture and condensation during insulation installation. I developed a deep understanding of vapor barriers and air sealing techniques to prevent moisture buildup and ensure the longevity of the insulation.

9. How do you calculate the R-value required for a building in different climate zones?

I use the International Energy Conservation Code (IECC) or local building codes to determine the minimum R-value requirements for walls, ceilings, and floors based on the climate zone of the building.

To calculate the total R-value required, I consider the type and thickness of the insulation materials used, as well as the thermal resistance of any existing building components like studs, drywall, or sheathing.

10. Describe the different types of insulation inspection and assessment techniques.

- Visual Inspection: Examining the insulation for visible damage, gaps, or missing sections.

- Thermal Imaging: Using a thermal camera to detect areas of heat loss or inadequate insulation.

- Blower Door Test: Measuring the air leakage rate of the building to assess the effectiveness of air sealing and insulation.

- Infrared Thermometer: Taking temperature readings to identify areas of heat transfer and potential insulation issues.

- Moisture Meter: Checking for moisture content in insulation to prevent mold growth and damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Workers are responsible for the installation and maintenance of insulation materials in various industrial and commercial settings. They work on projects of all sizes, from small residential homes to large industrial plants, and they use a variety of materials and techniques to achieve the desired results.

1. Installing Insulation

Insulation Workers typically begin by preparing the surface to be insulated. This may involve cleaning the surface, removing any existing insulation, and applying a primer or adhesive. Once the surface is prepared, the Insulation Worker will cut and fit the insulation material to the desired shape and size.

2. Maintaining Insulation

Once insulation is installed, it must be maintained to ensure that it continues to perform as intended. Insulation Workers are responsible for inspecting insulation regularly and repairing any damage that may occur. They may also need to clean insulation or replace it if it becomes damaged or contaminated.

3. Safety Regulations

Insulation Workers must be aware of and comply with all applicable safety regulations. This includes wearing appropriate safety gear and following safe work practices. Insulation Workers may also be required to work in confined spaces or on elevated surfaces, so they must be comfortable working in these conditions.

4. Communication Skills

Insulation Workers must be able to communicate effectively with other workers, supervisors, and clients. They may need to explain the benefits of different insulation materials, answer questions about the installation process, and provide advice on maintenance and repair.

Interview Tips

To ace an interview for an Insulation Worker position, it’s important to be prepared and to demonstrate your skills and knowledge. Here are a few tips to help you prepare:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their business, their culture, and the specific requirements of the position you’re applying for. You can find information about the company on their website, in industry publications, or by talking to people who work there.

2. Practice Your Answers

Once you’ve researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions you may be asked include:

- Tell me about your experience with insulation materials.

- What are the different types of insulation materials and how do they compare?

- How do you install insulation in different types of buildings?

- What are the safety regulations that apply to Insulation Workers?

- How do you communicate with other workers, supervisors, and clients?

3. Bring Examples of Your Work

If possible, bring examples of your work to your interview. This could include photos of insulation projects you’ve completed, samples of insulation materials, or letters of recommendation from previous employers. This will help the interviewer see your skills and experience firsthand.

4. Dress Professionally

Dress professionally for your interview. This shows the interviewer that you’re taking the interview seriously and that you’re committed to making a good impression.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, be confident, and be yourself, and you’ll be well on your way to acing your interview.

Next Step:

Now that you’re armed with the knowledge of Insulation Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Insulation Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini