Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Jewel Flat Surfacer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Jewel Flat Surfacer so you can tailor your answers to impress potential employers.

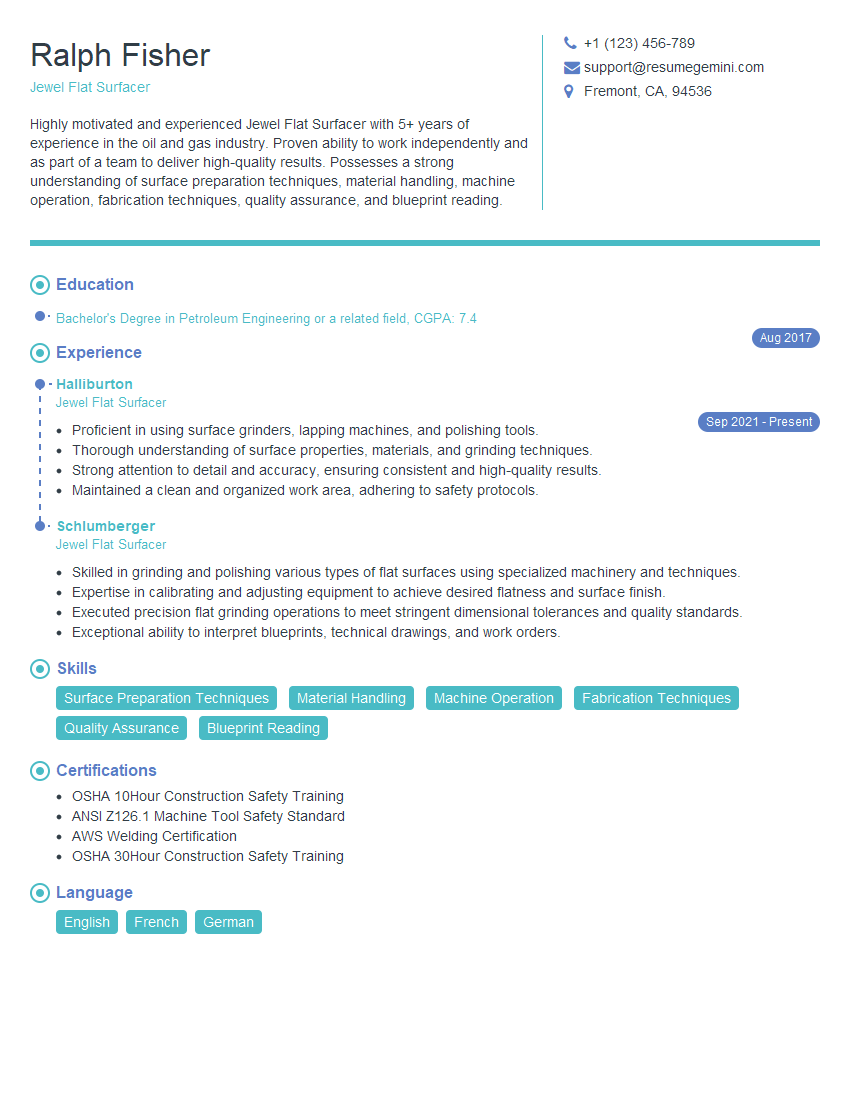

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewel Flat Surfacer

1. What are some of the most common materials that Jewel Flat Surfacers can be used on?

- Quartz

- Granite

- Marble

- Concrete

- Tile

- Laminate

- Acrylic

2. What are the key Benefits of using Jewel Flat Surfacers?

Increased Efficiency and Productivity

- Faster project completion times

- Reduced labor costs

- Improved surface finishes

Reduced Costs

- Less material waste

- Lower labor costs

- Increased equipment utilization

Improved Quality

- More consistent surface finishes

- Fewer defects

- Increased customer satisfaction

3. What are the different types of Jewel Flat Surfacers available?

There are two main types of Jewel Flat Surfacers: manual and automatic.

- Manual Jewel Flat Surfacers are operated by hand and require the operator to move the machine over the surface to be flattened.

- Automatic Jewel Flat Surfacers are powered by a motor and automatically move over the surface to be flattened.

4. What are some of the factors that affect the performance of Jewel Flat Surfacers?

- The type of material being flattened

- The size and shape of the surface being flattened

- The speed and feed rate of the machine

- The condition of the machine

5. What are some of the safety precautions that should be taken when using Jewel Flat Surfacers?

- Wear proper safety gear, including eye protection, hearing protection, and gloves.

- Make sure the machine is properly grounded.

- Keep the work area clean and free of debris.

- Be aware of the location of all power cords and hoses.

- Do not operate the machine under the influence of drugs or alcohol.

6. What are some tips for using Jewel Flat Surfacers effectively?

- Use the correct type of machine for the job.

- Use the correct speed and feed rate for the material being flattened.

- Keep the machine in good condition.

- Follow all safety precautions.

7. What are some of the common problems that can occur when using Jewel Flat Surfacers?

- The machine may not be able to flatten the surface properly.

- The machine may be damaged if it is not used properly.

- The operator may be injured if they do not follow all safety precautions.

8. What types of surfaces can be polished by Jewel Flat Surfacers?

- Granite

- Marble

- Quartz

- Travertine

- Limestone

- Concrete

- Terrazzo

9. What are the features of different types of abrasives used in Jewel Flat Surfacers?

Diamond abrasives

- Very hard and durable

- Can be used on a wide variety of materials

- Expensive

Ceramic abrasives

- Less hard and durable than diamond abrasives

- Less expensive than diamond abrasives

- Can be used on a variety of materials

Silicon carbide abrasives

- Less hard and durable than diamond and ceramic abrasives

- Very inexpensive

- Can be used on a variety of materials

10. What are the steps involved in flattening a surface using a Jewel Flat Surfacer?

- Prepare the surface by removing any dirt or debris.

- Choose the correct type of abrasive for the material being flattened.

- Set the machine to the correct speed and feed rate.

- Move the machine over the surface to be flattened.

- Check the surface to make sure it is flat.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewel Flat Surfacer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewel Flat Surfacer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jewel Flat Surfacer is accountable for operating a flat surfacing machine to polish and refine the surfaces of jewelry items, ensuring that they meet the desired specifications and quality standards.

1. Prepare and set up the flat surfacing machine

Follow established procedures to prepare and set up the flat surfacing machine, ensuring that it is properly calibrated and adjusted for the specific job requirements.

- Check and maintain the machine’s functionality to ensure it operates at optimal efficiency.

- Select and install the appropriate grinding wheels and polishing pads based on the material and desired finish.

2. Load and secure jewelry items

Handle and load jewelry items onto the flat surfacing machine securely, using appropriate techniques to prevent damage or loss.

- Inspect jewelry items before loading to identify any defects or potential issues that may require special attention.

- Use jigs and fixtures to hold jewelry items in place, ensuring stability during the surfacing process.

3. Operate the flat surfacing machine

Operate the flat surfacing machine skillfully, following established protocols and safety guidelines to achieve the desired surface finish.

- Control the grinding and polishing process by adjusting parameters such as speed, pressure, and angle.

- Monitor the machine’s operation, making necessary adjustments to maintain consistency and prevent errors.

4. Polish and refine jewelry surfaces

Utilize various polishing techniques and materials to refine and enhance the surface of jewelry items, achieving a high level of smoothness and luster.

- Select and apply polishing compounds and brushes suitable for the type of metal or material being worked on.

- Polish and buff surfaces using appropriate techniques to remove scratches, blemishes, and restore the original shine.

5. Inspect and quality control

Inspect the finished jewelry items thoroughly to ensure they meet the required specifications and quality standards.

- Check for surface defects, scratches, or imperfections using appropriate inspection tools.

- Document and report any discrepancies or areas for improvement, contributing to continuous quality enhancement.

Interview Preparation Tips

To enhance your preparation for the Jewel Flat Surfacer interview, consider the following tips and insights:

1. Research the company and the role

Familiarize yourself with the company’s history, culture, and the specific requirements of the Jewel Flat Surfacer role. This will help you tailor your answers to demonstrate your understanding of the company’s needs and how your skills align with the position.

2. Practice your technical skills

Review the key job responsibilities and prepare to discuss your proficiency in operating flat surfacing machines, selecting appropriate tools and materials, and achieving high-quality surface finishes. You may also consider practicing your skills on sample jewelry pieces to showcase your expertise during the interview.

3. Highlight your attention to detail and precision

Emphasize your meticulous nature and ability to work with precision in your responses. Showcase your commitment to delivering exceptional results and maintaining a high level of quality in your work.

4. Prepare examples of your work

If possible, bring examples of your previous work or portfolio to the interview. This could include before-and-after photos of jewelry items you have resurfaced, demonstrating your skills and the quality of your work.

5. Be prepared to discuss your safety practices

In the jewelry industry, safety is paramount. Be prepared to discuss your adherence to safety protocols and your understanding of the potential hazards associated with operating flat surfacing machines.

Next Step:

Now that you’re armed with the knowledge of Jewel Flat Surfacer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Jewel Flat Surfacer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini