Feeling lost in a sea of interview questions? Landed that dream interview for Lap Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lap Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

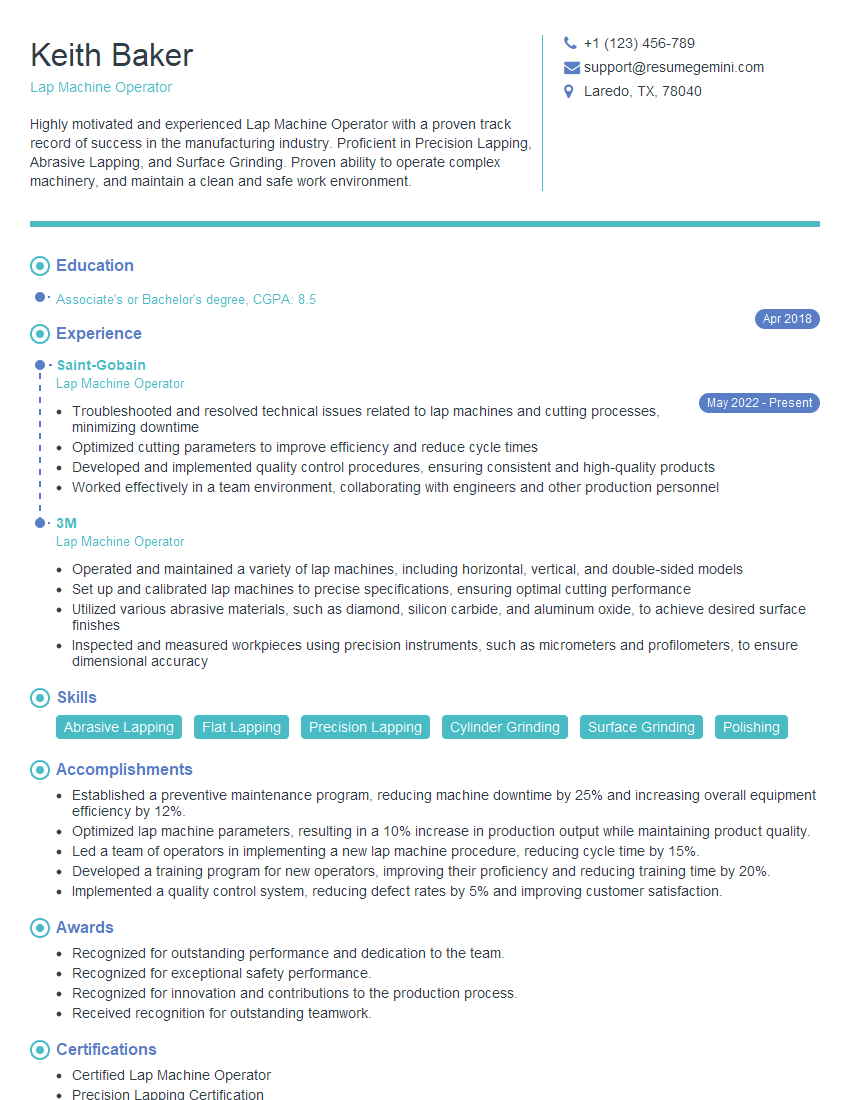

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lap Machine Operator

1. How would you approach troubleshooting an issue with a malfunctioning lap machine?

- Begin by observing the machine for any obvious signs of malfunction, such as unusual noises or vibrations.

- Check the machine’s control panel and display for any error messages or codes that could indicate the source of the problem.

- Refer to the machine’s user manual or technical specifications to identify potential causes of the issue and recommended troubleshooting steps.

- Inspect the machine’s components, including the lap plate, workpieces, and abrasives, to ensure they are properly installed and functioning correctly.

- If necessary, disassemble the machine to access internal components and conduct further diagnostics.

- Use diagnostic tools, such as a multimeter or oscilloscope, to measure electrical signals and identify faulty components.

- Once the source of the issue is identified, replace or repair the affected components and reassemble the machine.

- Perform a test run to verify that the machine is functioning correctly and within specifications.

2. How do you ensure that the surface finish of the lapped components meets the required specifications?

Inspection and Measurement

- Use a surface profilometer or other precision measuring instrument to measure surface roughness and other finish parameters.

- Compare the measured values to the specified tolerances and ensure compliance.

Process Control

- Adhere to established lapping parameters, such as lap speed, abrasive type and concentration, and lapping time.

- Monitor and adjust process variables to maintain consistent surface finish characteristics.

Abrasive Selection

- Choose the appropriate abrasive type, grit size, and concentration based on the material being lapped and the desired surface finish.

- Consider the abrasiveness, hardness, and durability of the abrasive to achieve the desired results.

3. How do you perform regular maintenance on a lap machine to ensure its longevity and precision?

- Regularly clean and lubricate the machine’s components, such as the lap plate, spindle, and bearings.

- Inspect and replace worn or damaged parts, such as abrasive discs or pads.

- Calibrate the machine’s sensors and controls to ensure accuracy and reliability.

- Monitor the machine’s performance and make adjustments as needed to maintain optimal operating conditions.

- Follow the manufacturer’s recommended maintenance schedule and use genuine parts for replacements.

4. What safety precautions do you observe when operating a lap machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat.

- Ensure the machine is properly grounded and electrically safe before operation.

- Keep hands and loose clothing away from moving parts, such as the lap plate and spindle.

- Use caution when handling abrasive materials and dispose of them properly.

- Follow established safety protocols and procedures as outlined by the manufacturer or workplace guidelines.

5. How do you optimize the lapping process for different materials, such as metals, ceramics, or composite materials?

- Consider the material’s hardness, brittleness, and surface characteristics.

- Adjust lapping parameters, such as lap speed, abrasive type, and pressure, to suit the material’s properties.

- Use specialized abrasives or lapping compounds designed for specific materials.

- Modify the lapping process sequence to achieve the desired surface finish and minimize material damage.

6. How do you maintain the accuracy and precision of the lap machine over time?

- Regularly calibrate the machine’s sensors and controls using traceable standards.

- Monitor and adjust machine parameters, such as lap speed and pressure, to ensure consistent performance.

- Inspect and replace worn or damaged components to maintain the machine’s integrity.

- Use high-quality abrasives and lapping compounds to minimize tool wear and maintain surface finish accuracy.

7. How do you troubleshoot common issues that may arise while operating a lap machine?

- Identify the symptoms or errors associated with the issue.

- Refer to the machine’s user manual or technical specifications for troubleshooting guidance.

- Inspect the machine’s components, such as the lap plate, spindle, and abrasives, for any visible damage or defects.

- Check electrical connections and sensors to ensure proper operation.

- Consult with experienced colleagues or technical support if necessary.

8. How do you ensure the safety of coworkers and yourself while working with a lap machine?

- Adhere to established safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat.

- Keep the work area clean and organized to prevent tripping or slipping hazards.

- Be aware of the location of emergency stop buttons and other safety features.

- Never operate the machine if it is damaged or malfunctioning.

9. How do you handle the disposal of used abrasives and lapping waste in an environmentally responsible manner?

- Follow established environmental guidelines and regulations for waste disposal.

- Segregate used abrasives and lapping waste from other materials.

- Dispose of abrasives and waste through authorized channels, such as licensed waste management companies.

- Consider recycling or reusing abrasives whenever possible.

10. How do you stay updated with the latest advancements and best practices in lap machine operation?

- Attend industry workshops, conferences, and training programs.

- Read technical journals and publications related to lap machine technology.

- Consult with experts in the field and stay informed about new developments.

- Participate in online forums and discussion groups to exchange knowledge and ideas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lap Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lap Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Lap Machine Operator, you will fulfill a diverse set of responsibilities that require precision, attention to detail, and a commitment to maintaining high-quality standards.

1. Machine Operation and Maintenance

Execute lap machine operations in a skillful and efficient manner to process materials meticulously.

- Set up and operate lap machines following established procedures and specifications

- Monitor machine performance, make necessary adjustments, and resolve operational issues promptly

- Perform routine maintenance and cleaning tasks to ensure optimal machine functionality

2. Material Preparation and Handling

Contribute to smooth production processes by effectively managing material preparation and handling.

- Inspect incoming materials to assess quality and ensure compliance with specifications

- Prepare and position materials on the lap machine for precise processing

- Handle materials safely and efficiently throughout the production process

3. Process Monitoring and Quality Control

Safeguard product quality by diligently monitoring processes and implementing quality control measures.

- Monitor lap machine operation closely to identify deviations from standard

- Conduct regular inspections and measurements to ensure adherence to specified tolerances

- Maintain accurate records and documentation related to production and quality control

4. Production Management

Actively contribute to maintaining efficient production schedules and meeting performance targets.

- Plan and prioritize work assignments to optimize production flow

- Monitor production progress and make necessary adjustments to maintain efficiency

- Identify areas for improvement and suggest process enhancements to increase productivity

Interview Tips

To effectively prepare for the interview, consider the following tips:

1. Research the Company and Position

Demonstrate your interest and preparedness by researching the company’s history, values, and the specific requirements of the Lap Machine Operator role.

2. Practice Answering Common Interview Questions

Familiarize yourself with typical interview questions by exploring online resources or reviewing practice materials.

- Example Question: Tell me about your experience operating lap machines.

- Example Outline:

- Begin with a brief overview of your experience.

- Highlight your proficiency in operating different types of lap machines.

- Provide specific examples of your ability to achieve precision and meet quality standards.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

3. Prepare Questions to Ask the Interviewer

Asking well-informed questions during the interview showcases your engagement and interest in the opportunity.

- Example Question: What is the company’s growth strategy for the next few years?

4. Dress Professionally and Arrive on Time

Convey respect for the interview process by dressing appropriately and punctually attending the scheduled interview time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lap Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.