Are you gearing up for an interview for a Last Turner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Last Turner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

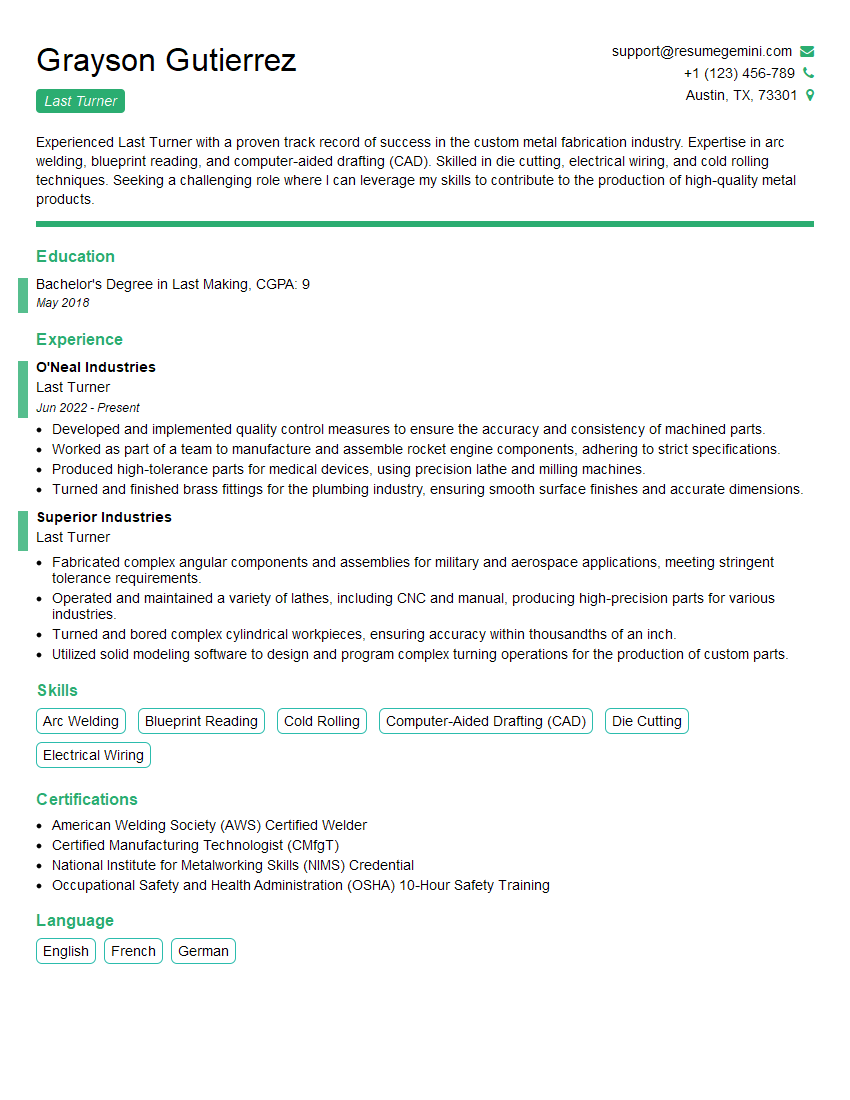

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Last Turner

1. What is the difference between soft and hard turning?

- Soft turning is a machining process that is used to remove material from a workpiece that is relatively soft, such as aluminum or brass.

- Hard turning is a machining process that is used to remove material from a workpiece that is relatively hard, such as steel or titanium.

2. What are the different types of cutting tools used in turning?

Single-point cutting tools

- Single-point cutting tools are the most common type of cutting tool used in turning.

- They are made of a single piece of material, such as carbide or high-speed steel.

- Single-point cutting tools are used to create a variety of different shapes and features on a workpiece.

Multi-point cutting tools

- Multi-point cutting tools have multiple cutting edges.

- They are used to create complex shapes and features on a workpiece.

- Multi-point cutting tools are more efficient than single-point cutting tools, but they are also more expensive.

3. What are the different types of turning machines?

- Engine lathes

- Turret lathes

- CNC lathes

4. What are the different types of turning operations?

- Straight turning

- Taper turning

- Facing

- Boring

- Knurling

5. What are the different safety precautions that must be taken when operating a turning machine?

- Wear appropriate safety gear, such as safety glasses, gloves, and a lab coat.

- Keep the work area clean and free of debris.

- Inspect the machine and cutting tools before each use.

- Secure the workpiece properly.

- Use the correct cutting speed and feed rate.

- Never leave the machine unattended while it is running.

6. What is the difference between a lathe and a milling machine?

- Lathes and milling machines are both machine tools that are used to remove material from a workpiece.

- Lathes are used to create cylindrical shapes, while milling machines are used to create flat surfaces.

- Lathes rotate the workpiece, while milling machines move the cutting tool.

7. What is the difference between a chuck and a collet?

- Chucks and collets are both devices that are used to hold a workpiece in place on a lathe.

- Chucks are typically used to hold larger workpieces, while collets are used to hold smaller workpieces.

- Chucks are more versatile than collets, but collets are more accurate.

8. What is the difference between a taper and a chamfer?

- A taper is a gradual reduction in the diameter of a workpiece.

- A chamfer is a beveled edge on a workpiece.

- Tapers are used to create a variety of different shapes and features on a workpiece, such as cones and pyramids.

- Chamfers are used to remove sharp edges from a workpiece and to improve the workpiece’s appearance.

9. What is the difference between a coolant and a lubricant?

- Coolants are used to cool the workpiece and the cutting tool during machining.

- Lubricants are used to reduce friction between the workpiece and the cutting tool.

- Coolants and lubricants can be used together to improve the machining process.

10. What is the difference between a single-pass and a multiple-pass turning operation?

- A single-pass turning operation is a turning operation that is completed in one pass of the cutting tool.

- A multiple-pass turning operation is a turning operation that is completed in multiple passes of the cutting tool.

- Single-pass turning operations are faster than multiple-pass turning operations, but they are also less accurate.

- Multiple-pass turning operations are slower than single-pass turning operations, but they are more accurate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Last Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Last Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Last turners play a crucial role in the production process, ensuring the final shaping and finishing of metal parts. Their key responsibilities include:

1. Final Turning Operations

Perform precise turning operations to achieve the desired shape, size, and finish of the workpiece.

2. Setup and Operation of Lathes

Set up, calibrate, and operate various lathes to machine metal parts accurately.

3. Tool and Fixture Selection and Use

Select, install, and operate cutting tools and fixtures to optimize machining efficiency and accuracy.

4. Measurement and Inspection

Measure and inspect parts against specifications using precision measuring instruments.

5. Quality Control and Assurance

Monitor machining operations to ensure quality standards are met, identifying and addressing any deviations.

Interview Tips

To prepare for an interview as a Last Turner, consider the following tips:

1. Research the Company and Role

Understand the company’s products, services, and industry, as well as the specific requirements of the Last Turner role.

2. Highlight Your Technical Skills

Emphasize your expertise in lathe operation, tool selection, and measurement techniques.

3. Showcase Your Precision and Accuracy

Provide examples of your ability to achieve high precision and accuracy in your work.

4. Discuss Your Problem-Solving Abilities

Explain how you handle troubleshooting and identify solutions to machining challenges.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare answers that demonstrate your skills and experience.

6. Practice Your Communication Skills

Articulate your technical knowledge and experience clearly and confidently.

7. Dress Professionally

Wear appropriate attire for an industrial setting, such as work boots, safety glasses, and coveralls.

8. Be Punctual and Respectful

Arrive on time for your interview and treat the interviewer with respect.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Last Turner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.