Feeling lost in a sea of interview questions? Landed that dream interview for Lathe Sander but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lathe Sander interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

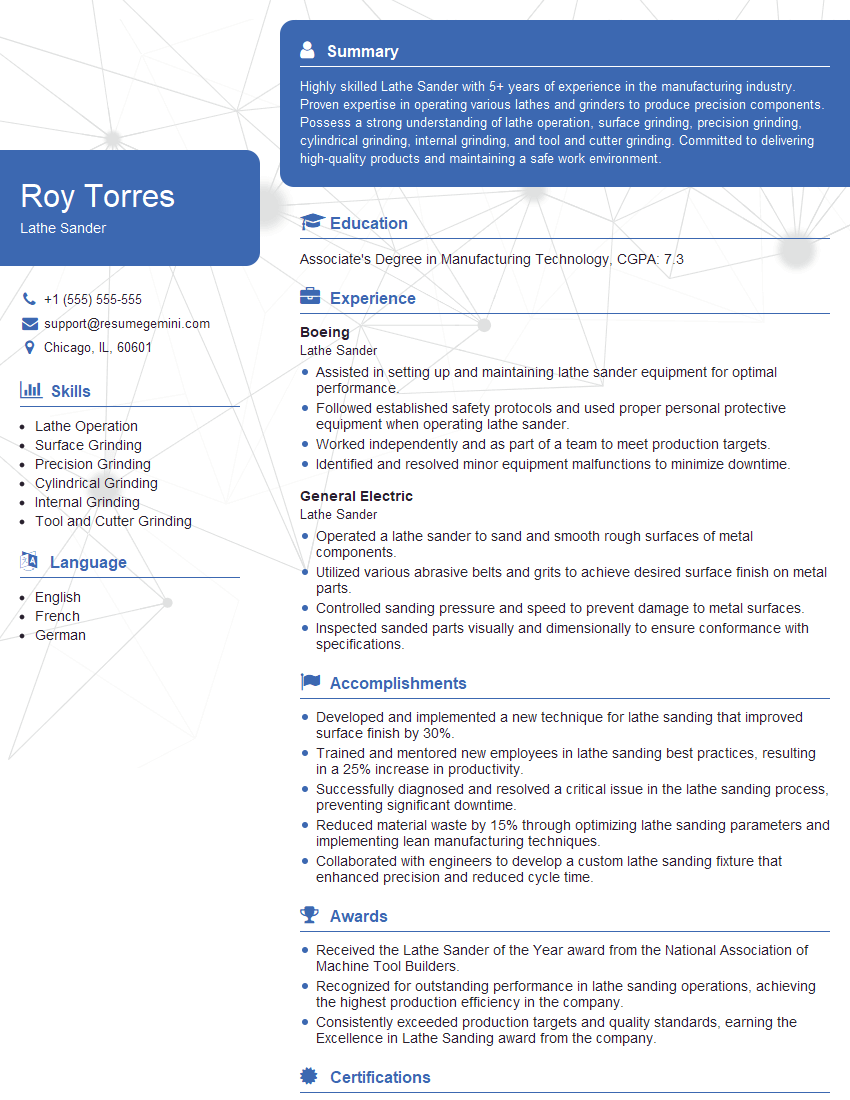

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lathe Sander

1. What are the main duties and responsibilities of a lathe sander?

As a lathe sander, my main responsibilities include:

- Operating and maintaining lathe sanding machines

- Sanding and finishing a variety of parts and products

- Ensuring that parts meet required specifications

- Monitoring machines and making adjustments as needed

- Maintaining a clean and organized work area

2. What types of materials can be sanded using a lathe sander?

Wood

- Hardwoods (such as oak, maple, and cherry)

- Softwoods (such as pine, fir, and cedar)

Metals

- Ferrous metals (such as steel and iron)

- Non-ferrous metals (such as aluminum, brass, and copper)

Plastics

- Acrylic

- Polyethylene

- Polypropylene

3. What are the different types of abrasives used in lathe sanding?

The different types of abrasives used in lathe sanding include:

- Aluminum oxide

- Silicon carbide

- Ceramic

- Diamond

- Cubic boron nitride

4. What are the different grits of sandpaper used in lathe sanding?

The different grits of sandpaper used in lathe sanding range from coarse to fine. Coarse grits (such as 40-80 grit) are used for removing large amounts of material. Medium grits (such as 120-220 grit) are used for smoothing surfaces. Fine grits (such as 320-600 grit) are used for finishing surfaces.

5. What are the different speeds and feeds used in lathe sanding?

The different speeds and feeds used in lathe sanding depend on the material being sanded, the type of abrasive being used, and the desired finish. Low speeds (such as 100-500 rpm) are used for sanding soft materials. High speeds (such as 1000-2000 rpm) are used for sanding hard materials. Low feeds (such as 0.001-0.005 inches per revolution) are used for sanding delicate materials. High feeds (such as 0.010-0.020 inches per revolution) are used for sanding heavy-duty materials.

6. What are the different types of lathe sanding machines?

The different types of lathe sanding machines include:

- Horizontal lathe sanding machines

- Vertical lathe sanding machines

- CNC lathe sanding machines

- Manual lathe sanding machines

7. What are the safety precautions that must be followed when using a lathe sander?

The safety precautions that must be followed when using a lathe sander include:

- Always wear appropriate safety gear, such as safety glasses, gloves, and a dust mask.

- Never operate a lathe sander while under the influence of alcohol or drugs.

- Always inspect the lathe sander before use to ensure that it is in good working condition.

- Never leave a lathe sander running unattended.

- Always use the appropriate speed and feed for the material being sanded.

8. What are the most common problems that can occur when using a lathe sander?

The most common problems that can occur when using a lathe sander include:

- Sanding marks

- Uneven sanding

- Burn marks

- Chatter

- Vibration

9. How do you troubleshoot and fix common problems that can occur when using a lathe sander?

Sanding marks

- Use a finer grit of sandpaper.

- Reduce the speed and feed of the lathe sander.

Uneven sanding

- Ensure that the workpiece is properly secured.

- Use a sanding block to evenly distribute the pressure.

Burn marks

- Reduce the speed and feed of the lathe sander.

- Use a coolant to prevent the workpiece from overheating.

Chatter

- Ensure that the workpiece is properly secured.

- Reduce the speed of the lathe sander.

Vibration

- Ensure that the lathe sander is properly balanced.

- Check the bearings and replace them if necessary.

10. What are the latest trends in lathe sanding technology?

The latest trends in lathe sanding technology include:

- The use of CNC lathe sanding machines

- The development of new abrasive materials

- The use of laser technology to improve the accuracy and precision of lathe sanding

- The development of new dust collection systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lathe Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lathe Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lathe Sanders are responsible for operating lathes to remove excess material from metal parts. They ensure that parts are sanded to the required specifications and quality standards.

1. Operate Lathes

Lathe Sanders must be able to operate lathes safely and efficiently. They must be familiar with the different types of lathes and how to use them to create different finishes.

- Set up and operate lathes

- Monitor the sanding process and make adjustments as needed

- Ensure that parts are sanded to the required specifications

2. Inspect Parts

Lathe Sanders must be able to inspect parts to ensure that they meet the required quality standards. They must be able to identify defects and take corrective action.

- Inspect parts for defects

- Identify and correct defects

- Ensure that parts meet the required quality standards

3. Maintain Equipment

Lathe Sanders must be able to maintain lathes and other equipment to ensure that they are in good working order. They must be able to identify and repair problems.

- Maintain lathes and other equipment

- Identify and repair problems

- Ensure that equipment is in good working order

4. Follow Safety Procedures

Lathe Sanders must be able to follow safety procedures to protect themselves and others from injury. They must be aware of the potential hazards of lathe operation and take appropriate precautions.

- Follow safety procedures

- Protect themselves and others from injury

- Be aware of the potential hazards of lathe operation

Interview Tips

To ace an interview for a Lathe Sander position, candidates should prepare by researching the company, the position, and the industry. They should also practice answering common interview questions and be prepared to discuss their skills and experience.

1. Research

Candidates should research the company, the position, and the industry before the interview. This will help them to understand the company’s culture, the requirements of the position, and the challenges and opportunities in the industry.

- Visit the company’s website

- Read industry publications

- Talk to people who work in the industry

2. Practice

Candidates should practice answering common interview questions. This will help them to feel more confident and prepared during the interview. They should also be prepared to discuss their skills and experience.

- Practice answering questions about their experience and skills

- Prepare questions to ask the interviewer

- Be prepared to discuss their career goals

3. Be Enthusiastic

Candidates should be enthusiastic about the position and the company. This will show the interviewer that they are genuinely interested in the job and that they would be a valuable asset to the team.

- Show interest in the position and the company

- Ask questions about the company and the position

- Be positive and upbeat

4. Be Professional

Candidates should be professional in their appearance and demeanor. This will show the interviewer that they are serious about the position and that they are a good fit for the company.

- Dress professionally

- Be on time for the interview

- Be polite and respectful

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lathe Sander, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lathe Sander positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.