Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lime Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lime Mixer so you can tailor your answers to impress potential employers.

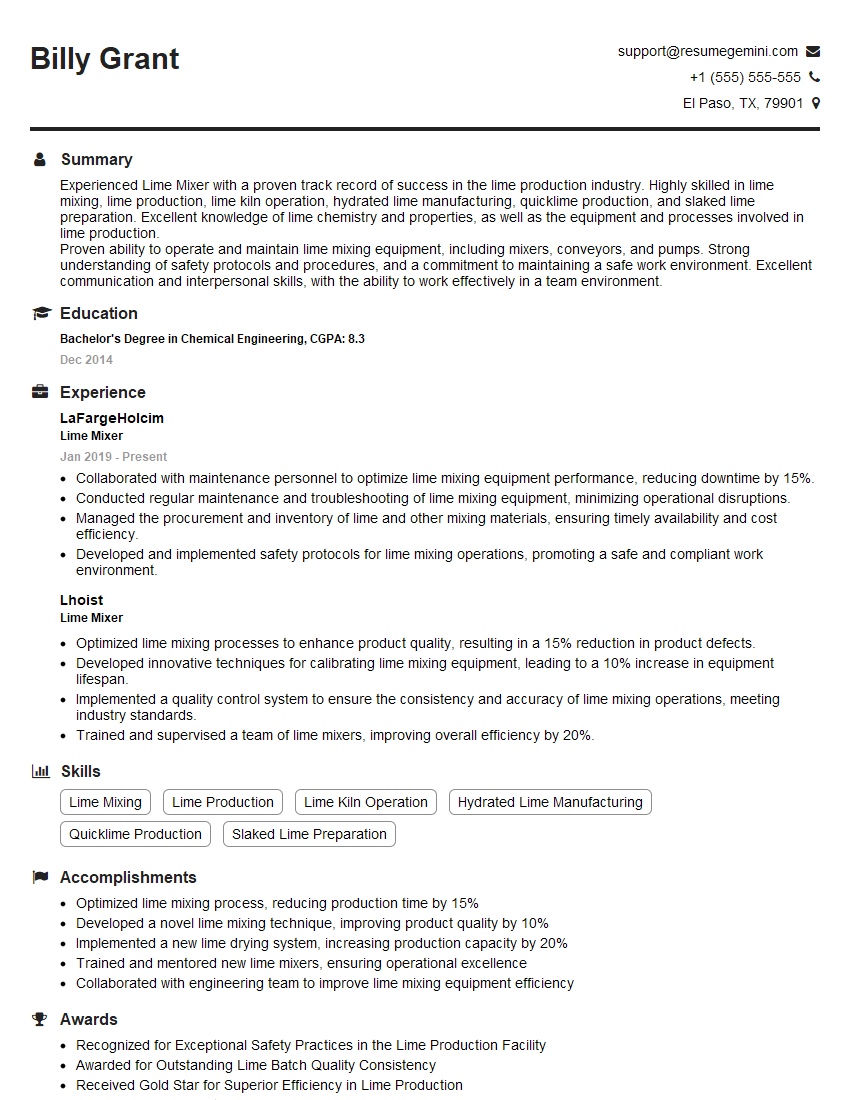

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lime Mixer

1. How do you ensure the correct proportions of raw materials are used in the lime mixing process?

To ensure the correct proportions of raw materials are used in the lime mixing process, I follow a standardized procedure:

- Raw material measurement: I use calibrated measuring devices to accurately measure the required quantities of lime, water, and any other additives.

- Batch weighing: Before mixing, I weigh each raw material individually to verify its weight against the specified proportions.

- Automated control systems: When available, I utilize automated control systems that precisely dispense the raw materials based on pre-programmed recipes.

- Regular monitoring: Throughout the mixing process, I monitor the consistency and composition of the lime slurry to ensure it meets the desired specifications.

2. Describe the different types of lime used in construction and their specific applications.

Quicklime (CaO)

- Highly reactive and generates heat when mixed with water.

- Used in water treatment, soil stabilization, and industrial processes.

- Requires careful handling and storage due to its caustic nature.

Hydrated Lime (Ca(OH)2)

- Less reactive and safer to handle than quicklime.

- Used in construction mortars, plasters, and as a soil amendment.

- Provides long-term strength and durability to building materials.

Dolomitic Lime (CaMg(CO3)2)

- Contains both calcium and magnesium oxides.

- Used in refractory materials, glass manufacturing, and soil conditioning.

- Provides high-temperature resistance and chemical stability.

3. What are the key performance indicators (KPIs) you track to measure the efficiency and effectiveness of the lime mixing process?

- Production output: Volume of lime slurry produced per hour or shift.

- Slurry consistency: Uniformity and flowability of the mixed lime slurry.

- Raw material consumption: Optimization of lime, water, and additive usage.

- Equipment utilization: Monitoring machine uptime and minimizing breakdowns.

- Process cycle time: Duration from raw material input to finished slurry output.

- Product quality: Compliance with specified chemical and physical properties.

4. Explain the importance of controlling the temperature during the lime mixing process.

- Chemical reactions: Mixing lime with water generates heat, which can affect the hydration rate and properties of the slurry.

- Slurry stability: Excessive heat can cause the slurry to thicken or set prematurely.

- Equipment protection: Overheating can damage mixing equipment and shorten its lifespan.

- Worker safety: High temperatures can create hazardous working conditions.

5. Describe the different types of mixing equipment used in lime mixing and their advantages and disadvantages.

Paddle Mixer

- Advantages: Gentle mixing action, suitable for delicate materials.

- Disadvantages: Slow mixing speed, limited shear force.

Ribbon Blender

- Advantages: Efficient mixing, uniform product, good for large batches.

- Disadvantages: Can create high shear forces, may damage sensitive materials.

Pug Mill Mixer

- Advantages: Continuous mixing, high shear forces, suitable for viscous materials.

- Disadvantages: Complex design, requires specialized maintenance.

6. What troubleshooting techniques do you use when encountering problems with the lime mixing process?

- Identify the issue: Observe the process and collect data to determine the root cause.

- Review process parameters: Check if raw material proportions, mixing time, or temperature are within specifications.

- Inspect equipment: Look for any wear or damage to mixing blades, seals, or other components.

- Calibrate instruments: Ensure measuring devices, such as scales and temperature sensors, are accurate and calibrated.

- Adjust process variables: Fine-tune mixing parameters based on observed issues and technical knowledge.

7. How do you ensure the safety of workers and equipment during the lime mixing process?

- Personal protective equipment (PPE): Provide and enforce the use of appropriate PPE, such as gloves, respirators, and eye protection.

- Hazard identification: Train workers on potential hazards, including chemical burns, dust inhalation, and equipment malfunctions.

- Safe work practices: Implement procedures for handling chemicals, operating equipment, and preventing accidents.

- Regular maintenance: Inspect and maintain equipment regularly to prevent breakdowns and improve safety.

- Emergency response plans: Develop and communicate emergency procedures in case of spills, fires, or other incidents.

8. Describe the environmental regulations and best practices for lime mixing and disposal.

- Emissions control: Implement measures to minimize dust and chemical emissions during mixing and disposal.

- Wastewater treatment: Treat wastewater generated from lime mixing processes to meet environmental standards.

- Landfill disposal: Follow proper disposal procedures and regulations for spent lime materials.

- Recycling and reuse: Explore options for recycling or reusing spent lime to minimize environmental impact.

- Compliance monitoring: Regularly monitor emissions and waste disposal practices to ensure compliance with environmental regulations.

9. How do you stay up-to-date on the latest advancements in lime mixing technology and best practices?

- Attend industry conferences and exhibitions: Network with experts and learn about new technologies.

- Read technical journals and publications: Stay informed about research and advancements in lime mixing.

- Participate in training and workshops: Enhance skills and knowledge through professional development opportunities.

- Consult with equipment manufacturers: Get insights on the latest mixing technologies and best practices.

- Network with peers: Exchange ideas and experiences with other lime mixing professionals.

10. As a Lime Mixer, what are your career goals and aspirations?

My career goal is to become a highly skilled and knowledgeable Lime Mixer. I am eager to contribute my expertise to the construction industry and play a role in delivering quality and sustainable building materials. I aspire to stay informed about the latest advancements in lime mixing technology and best practices to continuously improve my skills and knowledge. I am also interested in exploring opportunities for research and development, as well as training and mentoring junior team members.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lime Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lime Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lime Mixer is responsible for mixing and preparing lime-based materials used in a variety of industrial and construction applications. The key job responsibilities include:

1. Mixing Lime-Based Materials

Mixes various types of lime-based materials, including quicklime, hydrated lime, and agricultural lime according to specified proportions and quality standards.

2. Monitoring Process Parameters

Monitors mixing process parameters, such as temperature, pH, and consistency, and makes adjustments as needed to ensure proper mixing

3. Equipment Operation and Maintenance

Operates and maintains mixing equipment, including lime slakers, agitators, and pumps, ensuring their efficient and safe operation

4. Quality Control

Conducts quality control tests on lime-based materials to ensure they meet specifications and customer requirements

5. Safety and Compliance

Adheres to safety protocols and regulations related to the handling and use of lime-based materials

Interview Tips

Preparing for an interview for a Lime Mixer position requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Lime Mixer role. Researching the industry and understanding the applications of lime-based materials will also be beneficial.

2. Highlight Your Skills and Experience

Emphasize your technical skills in lime mixing, including your knowledge of different types of lime-based materials and your experience in operating and maintaining mixing equipment.

3. Prepare for Technical Questions

Anticipate technical questions related to the mixing process, quality control procedures, and safety protocols. Practice answering these questions clearly and concisely.

4. Showcase Your Safety Mindset

Lime handling can be hazardous, so it’s essential to demonstrate your understanding of safety protocols and your commitment to working in a safe environment.

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and the industry. Maintain a professional demeanor throughout the interview, and be prepared to ask thoughtful questions that demonstrate your interest and engagement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lime Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.