Are you gearing up for an interview for a Lime Sludge Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lime Sludge Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

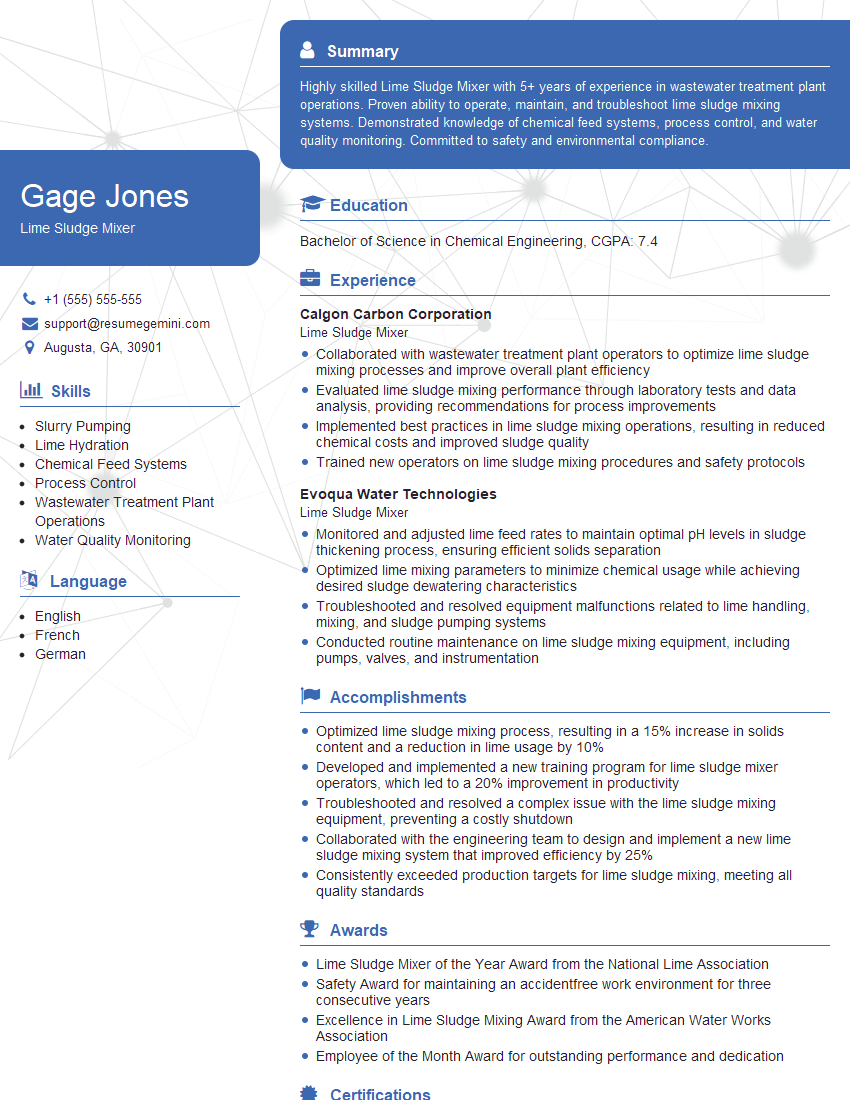

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lime Sludge Mixer

1. Explain the process of lime sludge mixing in detail?

- Slurry preparation: Lime is mixed with water to form a slurry.

- Slurry mixing: The lime slurry is then mixed with the sludge in a mixer.

- Flocculation: The mixed sludge is allowed to settle, during which the lime reacts with the sludge to form flocs.

- Sedimentation: The flocs settle to the bottom of the mixer, leaving behind clear water.

- Sludge thickening: The settled sludge is thickened to reduce its volume.

- Sludge dewatering: The thickened sludge is dewatered to remove excess water.

2. What are the different types of lime sludge mixers available?

Horizontal paddle mixer

- Uses a horizontal paddle to mix the sludge and lime.

- Suitable for small to medium-sized applications.

Vertical turbine mixer

- Uses a vertical turbine to mix the sludge and lime.

- Suitable for large-sized applications.

Inline mixer

- Mixes the sludge and lime as they flow through a pipe.

- Suitable for continuous mixing applications.

3. What are the key parameters to consider when selecting a lime sludge mixer?

- Volume of sludge to be mixed

- Type of sludge

- Desired mixing intensity

- Available space

- Budget

4. How do you maintain a lime sludge mixer?

- Regularly inspect the mixer for wear and tear.

- Lubricate the moving parts according to the manufacturer’s instructions.

- Clean the mixer regularly to remove sludge buildup.

- Calibrate the mixer regularly to ensure accurate mixing.

5. What are the potential problems that can occur with lime sludge mixers?

- Sludge buildup: Sludge can build up on the mixer blades, impeller, and other components, which can reduce mixing efficiency.

- Mechanical failure: The mixer can experience mechanical failures due to wear and tear, which can result in downtime.

- Electrical failure: The mixer can experience electrical failures due to faulty wiring, which can also result in downtime.

6. How do you troubleshoot a lime sludge mixer?

- Check for sludge buildup: If sludge has built up on the mixer, clean it off and restart the mixer.

- Check for mechanical failure: If the mixer is not operating properly, check for mechanical failure and repair or replace any damaged components.

- Check for electrical failure: If the mixer is not receiving power, check for electrical failure and repair or replace any faulty wiring.

7. What safety precautions should be taken when operating a lime sludge mixer?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Do not operate the mixer if it is damaged or malfunctioning.

- Keep the area around the mixer clean and free of debris.

- Be aware of the potential for explosions and fires when working with lime sludge.

8. What are the environmental regulations that apply to lime sludge mixing?

- The Clean Water Act: Lime sludge is considered a hazardous waste and must be disposed of in accordance with the Clean Water Act.

- The Resource Conservation and Recovery Act (RCRA): Lime sludge is also considered a hazardous waste under RCRA and must be managed in accordance with the regulations.

- The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA): Lime sludge is a listed hazardous substance under CERCLA and must be reported to the National Response Center in the event of a spill or release.

9. How do you stay up-to-date on the latest developments in lime sludge mixing?

- Read trade publications and attend industry conferences.

- Network with other professionals in the field.

- Take continuing education courses.

10. What are the challenges and opportunities in the field of lime sludge mixing?

Challenges

- The increasing volume of sludge being generated.

- The need to meet more stringent environmental regulations.

- The rising cost of energy and other resources.

Opportunities

- The development of new technologies for lime sludge mixing.

- The growing demand for lime sludge as a soil amendment.

- The potential for lime sludge to be used as a renewable energy source.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lime Sludge Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lime Sludge Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Lime Sludge Mixer is responsible for mixing lime with sludge to optimize wastewater treatment processes. This role requires a combination of technical skills and attention to detail to ensure efficient and compliant operations. Key responsibilities include:

1. Mixing Operations

Operate and maintain lime sludge mixing equipment to achieve the desired sludge characteristics and pH levels.

- Monitor and adjust mixing parameters such as speed, duration, and reagent dosage.

- Ensuring efficient mixing to achieve uniform distribution of lime throughout the sludge.

2. Process Monitoring

Monitor and maintain process variables such as temperature, pH, and sludge consistency.

- Conduct regular tests and analyze data to ensure compliance with process specifications.

- Identify and address any deviations from optimal operating conditions.

3. Equipment Maintenance

Perform routine maintenance and cleaning of mixing equipment to maximize performance.

- Inspect and lubricate machinery components.

- Troubleshoot and repair minor equipment malfunctions.

4. Safety and Compliance

Adhere to all safety regulations and company policies related to chemical handling and equipment operation.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

To ace your interview for the Lime Sludge Mixer position, it’s crucial to prepare thoroughly and showcase your technical knowledge and skills. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s values, services, and wastewater treatment processes.

- Visit the company website and read about their mission, operations, and sustainability initiatives.

- Research industry trends and best practices in lime sludge mixing.

2. Practice Your Answers

Prepare for common interview questions by practicing your responses. Focus on highlighting your relevant skills and experience.

- Explain your understanding of lime sludge mixing processes and their importance in wastewater treatment.

- Describe your experience in operating and maintaining mixing equipment.

3. Emphasize Safety and Compliance

Lime sludge mixing involves handling chemicals and operating equipment. Stress your commitment to safety and compliance.

- Highlight your knowledge of safety regulations and best practices.

- Explain how you ensure a safe and compliant work environment.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you’re engaged and interested in the position. Prepare questions that demonstrate your curiosity and knowledge of the industry.

- Ask about the company’s approach to sustainability and environmental stewardship.

- Inquire about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lime Sludge Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!