Are you gearing up for a career in Liquor Grinder Mill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Liquor Grinder Mill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

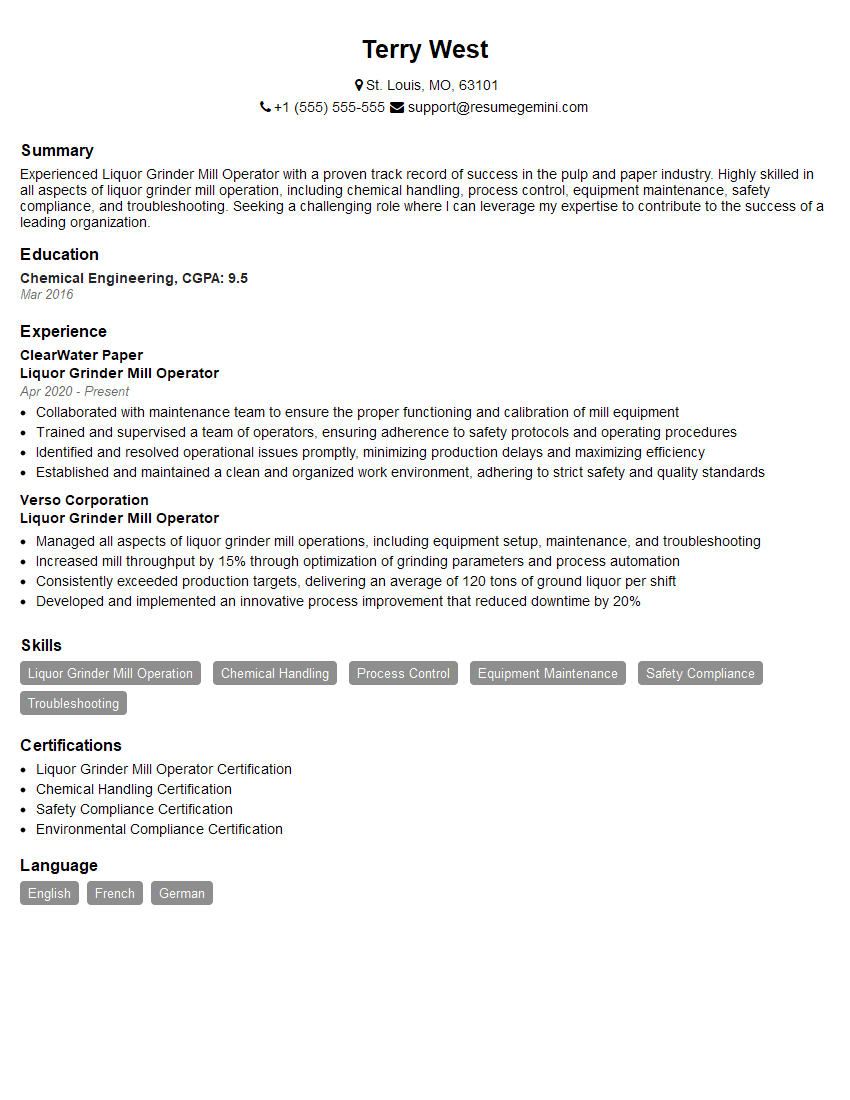

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquor Grinder Mill Operator

1. What are the key responsibilities of a Liquor Grinder Mill Operator?

- Operate and maintain liquor grinder mills to grind malt or other materials into a fine powder.

- Monitor the grinding process and make adjustments to ensure the desired consistency is achieved.

- Clean and maintain the mill and its components to prevent contamination and ensure efficient operation.

- Work with other team members to ensure the smooth and efficient flow of materials and products.

- Follow established safety procedures and guidelines to ensure a safe work environment.

2. Describe the different types of liquor grinder mills and their applications.

Hammer mills

- Use high-speed rotating hammers to crush and grind materials.

- Suitable for grinding a wide range of materials, such as malt, grains, and spices.

Roller mills

- Use two or more rollers to crush and grind materials by compression.

- Capable of producing a finer grind than hammer mills.

- Suitable for grinding materials that are not easily crushed, such as cereals and oilseeds.

Disc mills

- Use rotating discs to grind materials by friction.

- Produce a very fine grind and are often used for grinding minerals and chemicals.

3. How do you ensure that the ground liquor meets the desired specifications?

- Monitor the grinding process closely and make adjustments to the mill settings as needed.

- Take samples of the ground liquor and test them for consistency and other quality parameters.

- Make adjustments to the grinding process based on the test results to ensure that the desired specifications are met.

- Keep records of the grinding process and test results for quality control purposes.

- Work with the quality control department to ensure that the ground liquor meets the required standards.

4. What are the common maintenance tasks associated with liquor grinder mills?

- Cleaning the mill and its components to prevent contamination and ensure efficient operation.

- Inspecting and replacing worn or damaged parts, such as hammers, rollers, or discs.

- Lubricating the mill’s moving parts to prevent wear and tear.

- Calibrating the mill to ensure that it is operating correctly.

- Performing preventive maintenance tasks, such as cleaning and inspecting the mill on a regular basis, to prevent breakdowns.

5. How do you troubleshoot common problems associated with liquor grinder mills?

- Identify the problem by observing the mill’s operation and listening for unusual noises or vibrations.

- Check the mill’s settings and make adjustments as needed.

- Inspect the mill’s components for wear or damage and replace or repair as necessary.

- Clean the mill and its components to remove any obstructions or contamination.

- Consult with the mill’s manufacturer or a qualified mechanic if the problem cannot be resolved.

6. What are the safety precautions that must be taken when operating a liquor grinder mill?

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep the mill area clean and free of debris.

- Never operate the mill with the covers removed.

- Do not put your hands or any other objects into the mill while it is operating.

- Be aware of the mill’s moving parts and keep a safe distance.

- Follow all established safety procedures and guidelines.

7. Describe the process of calibrating a liquor grinder mill.

- Clean the mill and its components to remove any debris or contamination.

- Inspect the mill’s components for wear or damage and replace or repair as necessary.

- Follow the manufacturer’s instructions for calibrating the mill.

- Use a calibrated gauge to measure the mill’s output and make adjustments as needed.

- Test the mill’s calibration by grinding a sample of material and comparing the results to the desired specifications.

8. What are the different types of materials that can be ground in a liquor grinder mill?

- Malt

- Grains

- Spices

- Cereals

- Oilseeds

- Minerals

- Chemicals

9. How do you maintain a clean and sanitary work environment around the liquor grinder mill?

- Clean the mill and its components regularly to remove any debris or contamination.

- Sweep and mop the floor around the mill to keep it clean.

- Dispose of waste materials properly.

- Follow all established sanitation procedures.

- Work with the housekeeping staff to ensure that the work area is clean and sanitary.

10. Describe the importance of proper maintenance for a liquor grinder mill.

- Prevents breakdowns and costly repairs.

- Ensures that the mill is operating efficiently and producing the desired results.

- Reduces the risk of accidents and injuries.

- Extends the life of the mill.

- Helps to maintain a clean and sanitary work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquor Grinder Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquor Grinder Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Liquor Grinder Mill Operators play a vital role in the production of paper by grinding wood chips into a fine pulp. Their key responsibilities include:

1. Grinding Operations

Operate and maintain liquor grinders to grind wood chips into pulp.

- Monitor grinder performance and adjust settings as needed.

- Ensure proper flow of wood chips and liquor through the grinder.

2. Pulp Quality Control

Inspect and test pulp samples to ensure it meets quality specifications.

- Analyze pulp characteristics such as consistency, brightness, and freeness.

- Make adjustments to grinder settings or other process parameters to maintain desired pulp quality.

3. Equipment Maintenance

Perform routine maintenance and repairs on liquor grinders and related equipment.

- Inspect and clean equipment to prevent breakdowns.

- Replace worn or damaged parts and lubricate moving components.

4. Safety and Environmental Compliance

Follow safety protocols and maintain a clean and safe work environment.

- Wear appropriate personal protective equipment.

- Adhere to environmental regulations regarding wastewater and emissions.

Interview Preparation Tips

1. Research the Company and Role

Gather information about the company, its products, and the specific responsibilities of the Liquor Grinder Mill Operator position. This will help you understand the company’s expectations and prepare tailored answers.

2. Review Industry Knowledge and Terminology

Familiarize yourself with the terminology and processes used in pulp and paper manufacturing. This will demonstrate your understanding of the industry and your ability to communicate effectively with other team members.

3. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize your experience in operating and maintaining grinding equipment. Highlight your skills in pulp quality control, equipment maintenance, and safety compliance.

4. Prepare Examples of Successes

Provide specific examples of how you have successfully managed grinding operations, maintained equipment, and resolved production issues. This will help the interviewer visualize your abilities and assess your problem-solving skills.

5. Dress Professionally and Arrive Punctually

Dress professionally for the interview and arrive on time. This shows respect for the interviewer and the company, and creates a positive first impression.

6. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the role and the company. It also gives you an opportunity to clarify any details and demonstrate your enthusiasm for the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Liquor Grinder Mill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Liquor Grinder Mill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.