Are you gearing up for an interview for a Lithographers Printer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lithographers Printer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

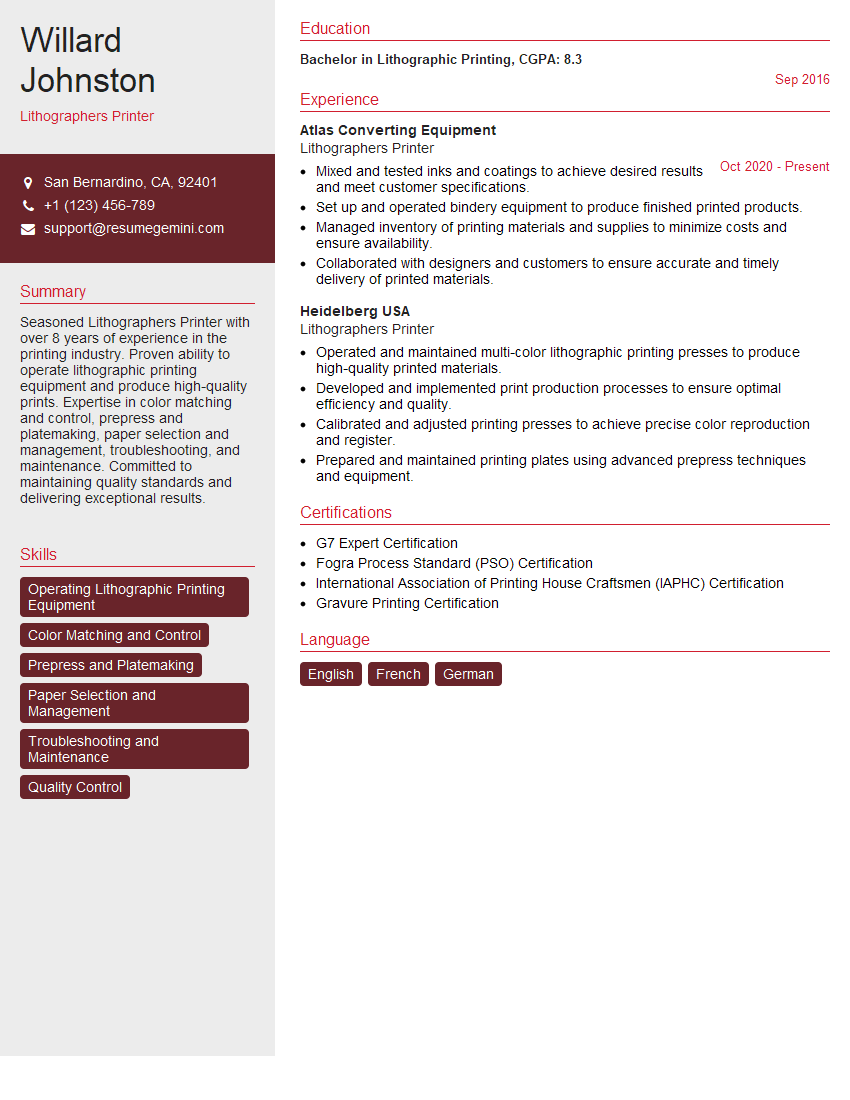

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lithographers Printer

1. Describe the key steps involved in the lithographic printing process?

The lithographic printing process involves several key steps:

- Prepress: Preparing the digital or physical artwork for printing, including color separation, image editing, and plate creation.

- Platemaking: Transferring the artwork onto printing plates using a photographic or laser engraving process.

- Press Setup: Setting up the printing press, including loading the plates, adjusting ink and water levels, and registering the paper.

- Printing: Running the paper through the press, where ink is transferred from the plates to the paper using a water-based process that repels ink in non-image areas.

- Postpress: Finishing operations such as cutting, folding, binding, and drying the printed sheets.

2. Explain the principles of color separation and how they are used in lithography?

Color Theory

- Lithography uses the subtractive color model (CMYK), which combines cyan, magenta, yellow, and black inks to create a wide range of colors.

- Color separation involves dividing the original artwork into these individual color components.

Separation Process

- During prepress, the artwork is scanned or photographed to create digital images.

- Software separates these images into individual plates for each color, ensuring that the colors align accurately during printing.

3. What are the different types of lithographic printing presses and their advantages?

- Sheet-fed Presses: Suitable for short to medium print runs, offer high precision and quality.

- Web Presses: High-speed presses designed for long print runs, such as newspapers or magazines.

- Offset Presses: Use an intermediary blanket cylinder to transfer ink from the plate to the paper, resulting in cleaner and higher-quality prints.

4. Describe the different types of paper used in lithographic printing and their properties?

Lithographic printing requires paper with specific characteristics:

- Brightness: Paper brightness affects color reproduction and contrast.

- Opacity: Prevents show-through of printing from the reverse side.

- Smoothness: Smooth paper surfaces allow for sharp and detailed printing.

- Absorption: Paper should absorb ink evenly to prevent smudging or bleeding.

- Weight: The thickness and weight of the paper affect handling, durability, and printability.

5. How do you ensure accurate color reproduction in lithographic printing?

- Calibration: Regularly calibrate printing equipment, including the press, plates, and inks.

- Color Management: Use color management systems to ensure consistent color across different devices and processes.

- Proofing: Create and approve printed proofs before full production to verify color accuracy.

- Color Matching: Match colors using color libraries or spectrophotometers to achieve precise results.

6. What are the common troubleshooting tips for addressing printing defects in lithography?

- Registration Issues: Adjust plate alignment or press settings to correct misalignment.

- Color Variation: Check ink levels, plate quality, or press temperature to ensure consistent color reproduction.

- Smudging or Bleeding: Use proper paper, adjust ink viscosity, or increase drying time.

- Ghosting: Check press settings, blanket condition, or plate cleanliness to eliminate unwanted ink transfer.

- Dot Gain: Control ink-water balance, adjust press settings, or use different plates to reduce dot enlargement.

7. Explain the role of ink and water in lithographic printing?

Ink

- Lithographic inks are water-based and contain pigments that determine color.

- Ink viscosity affects the flow and transfer of ink during printing.

Water

- Water is used to keep non-image areas free of ink, as water repels oil-based inks.

- The water-ink balance is critical for proper printing and defect prevention.

8. Describe the safety precautions that must be followed when operating lithographic printing equipment?

- Wear appropriate safety gear, including gloves, goggles, and hearing protection.

- Follow lockout/tagout procedures when servicing or cleaning equipment.

- Handle chemicals and inks according to safety data sheets (SDS).

- Maintain a clean and organized work area to minimize tripping hazards.

- Report any malfunctions or accidents immediately.

9. What are the qualities of a successful lithographic printer?

- Strong technical skills in lithographic printing principles.

- Ability to operate and maintain printing equipment.

- Excellent color vision and attention to detail.

- Problem-solving skills and troubleshooting abilities.

- Knowledge of prepress and postpress processes.

10. How do you stay updated with the latest advancements in lithographic printing technology?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Network with other lithographic printers and professionals.

- Pursue continuing education or certification programs.

- Explore online resources and manufacturer websites for new technologies and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lithographers Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lithographers Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lithographers Printers are responsible for operating printing presses to produce high-quality print materials. They work closely with prepress and postpress teams to ensure that print jobs are completed according to specifications.

1. Preparing the Press

Lithographers Printers prepare the printing press by loading paper, adjusting ink levels, and setting up the press according to the job specifications. They also inspect the press to ensure that it is functioning properly.

- Loading paper into the press

- Adjusting ink levels

- Setting up the press according to job specifications

- Inspecting the press to ensure that it is functioning properly

2. Printing the Job

Lithographers Printers operate the printing press to print the job. They monitor the press during printing to ensure that the print quality meets specifications. They also make adjustments to the press as needed to maintain print quality.

- Operating the printing press to print the job

- Monitoring the press during printing to ensure that the print quality meets specifications

- Making adjustments to the press as needed to maintain print quality

3. Finishing the Job

Lithographers Printers finish the job by removing the printed sheets from the press and inspecting them for quality. They also perform post-press operations such as cutting, folding, and binding the printed sheets.

- Removing the printed sheets from the press

- Inspecting the printed sheets for quality

- Performing post-press operations such as cutting, folding, and binding the printed sheets

4. Maintaining the Press

Lithographers Printers are responsible for maintaining the printing press. They perform regular maintenance tasks such as cleaning the press, lubricating moving parts, and replacing worn parts. They also troubleshoot and repair problems with the press as needed.

- Performing regular maintenance tasks such as cleaning the press, lubricating moving parts, and replacing worn parts

- Troubleshooting and repairing problems with the press as needed

Interview Tips

To prepare for an interview as a Lithographers Printer, you should:

1. Research the company and the position

Learn about the company’s culture, products, and services. You should also research the specific position you are applying for. This will help you understand the company’s needs and how your skills and experience can meet those needs.

- Visit the company’s website

- Read industry publications

- Talk to people who work at the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” You should practice answering these questions in a clear and concise manner.

- Use the STAR method to answer behavioral interview questions

- Be prepared to talk about your skills and experience

- Be able to articulate why you are interested in the position and the company

3. Dress professionally and arrive on time

First impressions matter, so you should dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Be punctual for your interview

- Make eye contact and smile when you meet the interviewer

4. Be enthusiastic and positive

The interviewer will be able to tell if you are passionate about the position and the company. Be enthusiastic and positive in your answers, and let the interviewer know why you are excited about the opportunity.

- Show your passion for the printing industry

- Be positive and enthusiastic about the company and the position

- Let the interviewer know why you are excited about the opportunity

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lithographers Printer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lithographers Printer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.