Are you gearing up for a career in Lozenge Dough Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lozenge Dough Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

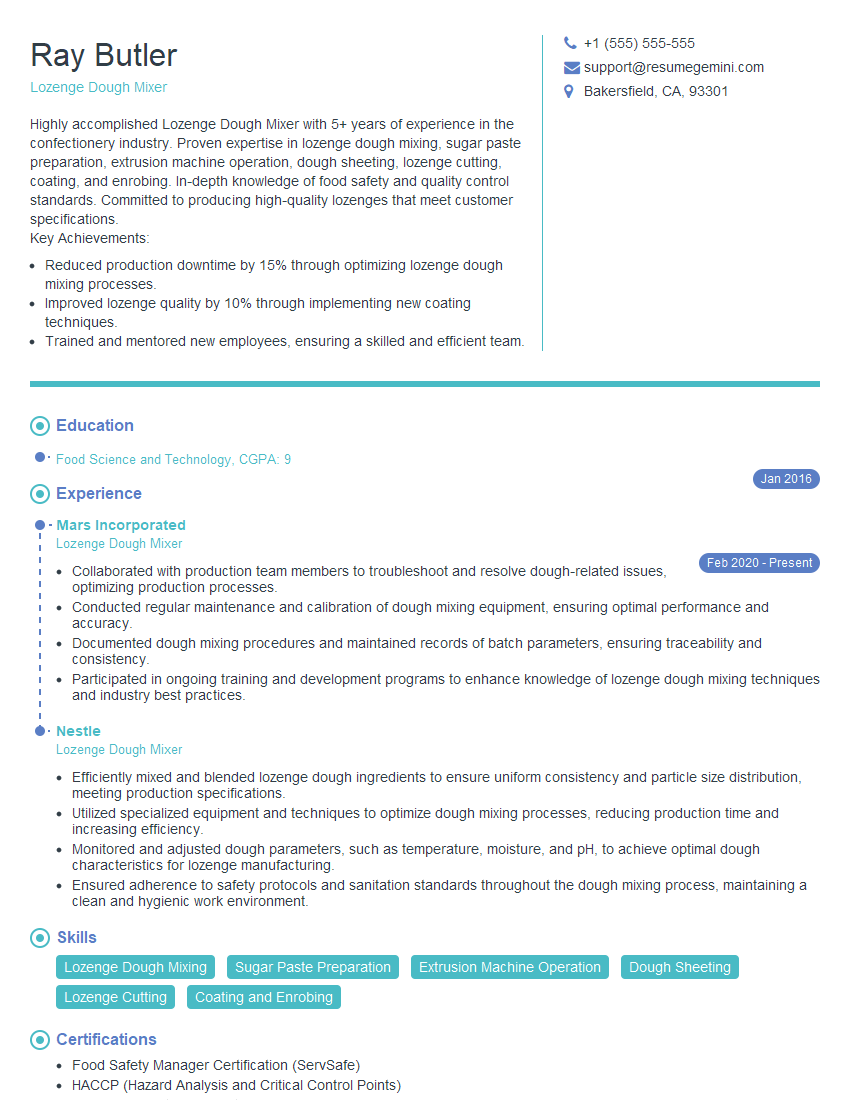

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lozenge Dough Mixer

1. Describe the key components of a Lozenge Dough Mixer and explain their functions.

The key components of a Lozenge Dough Mixer are:

- Mixing bowl: The mixing bowl is the main component of the mixer and holds the ingredients while they are being mixed.

- Mixing blades: The mixing blades are attached to the mixing bowl and rotate to mix the ingredients.

- Motor: The motor powers the mixing blades and provides the torque necessary to mix the ingredients.

- Control panel: The control panel allows the operator to set the mixing speed and time.

2. Explain the different types of mixing actions available on a Lozenge Dough Mixer.

Conventional Mixing

- Mixing blades rotate in one direction only.

- Creates a homogeneous mix.

Planetary Mixing

- Mixing blades rotate around the central axis while also rotating on their own axis.

- Provides a more thorough mix, preventing lumps.

Orbital Mixing

- Mixing blades move in an orbital motion, creating a whirlpool effect.

- Suitable for mixing delicate ingredients without damaging them.

3. What are the key factors to consider when selecting a Lozenge Dough Mixer?

The key factors to consider when selecting a Lozenge Dough Mixer include:

- Capacity: Choose a mixer with a mixing bowl capacity that meets your production needs.

- Mixing speed: Consider the speed range of the mixer to ensure it aligns with your mixing requirements.

- Mixing action: Select a mixer that provides the type of mixing action most suitable for your products.

- Durability: Opt for a mixer constructed with high-quality materials to ensure longevity in demanding environments.

- Safety features: Verify the mixer has essential safety features to protect operators during operation.

4. Describe the maintenance procedures for a Lozenge Dough Mixer to ensure its optimum performance.

- Regularly clean the mixing bowl and blades to prevent contamination.

- Lubricate the moving parts as per manufacturer’s recommendations to minimize wear and tear.

- Inspect the motor, wiring, and control panel for any damage or loose connections.

- Perform scheduled maintenance as outlined by the manufacturer to ensure longevity and peak performance.

- Keep a maintenance log to track inspections and repairs for future reference.

5. Explain the troubleshooting steps to take when a Lozenge Dough Mixer is not functioning properly.

- Check the power supply to ensure the mixer is receiving electricity.

- Inspect the mixing bowl and blades for any damage or obstruction.

- Verify the motor is running and the mixing blades are rotating properly.

- Examine the control panel to confirm the settings are correct.

- Consult the manufacturer’s manual for specific troubleshooting guidance.

6. Describe the safety precautions to observe when operating a Lozenge Dough Mixer.

- Ensure the mixer is properly grounded to prevent electrical hazards.

- Never operate the mixer without the mixing bowl and blades securely attached.

- Keep hands and loose clothing away from moving parts.

- Do not overload the mixer beyond its capacity.

- Follow all manufacturer’s instructions for safe operation.

7. Explain the process of mixing lozenges in a Lozenge Dough Mixer.

Mixing lozenges in a Lozenge Dough Mixer involves the following steps:

- Prepare the lozenge ingredients according to the recipe.

- Place the ingredients into the mixing bowl of the mixer.

- Set the mixing speed and time according to the lozenge recipe.

- Start the mixer and allow it to mix the ingredients until a uniform dough is formed.

- Remove the dough from the mixing bowl and proceed with the next steps of the lozenge-making process.

8. Describe the different types of dough consistencies that can be achieved using a Lozenge Dough Mixer.

The different types of dough consistencies that can be achieved using a Lozenge Dough Mixer include:

- Firm dough: This type of dough is stiff and holds its shape well, making it suitable for products like cookies and crackers.

- Medium dough: This type of dough is somewhat softer and pliable, making it ideal for products like bread and pizza dough.

- Soft dough: This type of dough is very soft and sticky, making it suitable for products like cakes and muffins.

9. Explain the factors that affect the mixing time of lozenges in a Lozenge Dough Mixer.

- Type of lozenge ingredients: Different ingredients, such as flour, sugar, and flavorings, have different mixing times.

- Quantity of lozenge ingredients: A larger quantity of ingredients will require a longer mixing time.

- Mixing speed: A higher mixing speed will reduce the mixing time.

- Desired dough consistency: A firmer dough consistency will require a longer mixing time.

- Temperature of the lozenge ingredients: Cold ingredients will require a longer mixing time.

10. Describe how to maintain the quality of lozenges mixed in a Lozenge Dough Mixer.

- Use high-quality ingredients to ensure the best possible flavor and texture.

- Follow the manufacturer’s instructions for mixing lozenges to achieve the correct consistency.

- Store the mixed lozenge dough in a cool, dry place to prevent spoilage.

- Use the mixed lozenge dough within a few days to ensure freshness.

- Clean the Lozenge Dough Mixer thoroughly after each use to prevent contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lozenge Dough Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lozenge Dough Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lozenge Dough Mixers play a significant role in the confectionery industry, handling dough preparation for lozenges and other similar products. To excel in this role, you must possess a thorough understanding of lozenge dough preparation and the associated equipment.

1. Dough Preparation and Mixing

Your primary responsibility will be to prepare and mix lozenge dough according to specified recipes and quality standards.

- Measure and weigh ingredients accurately to ensure precise dough composition.

- Operate and maintain lozenge dough mixers to blend ingredients thoroughly and achieve desired consistency.

2. Equipment Operation and Maintenance

You will be responsible for operating and maintaining the lozenge dough mixing equipment.

- Set up, operate, and clean dough mixers efficiently.

- Perform routine maintenance and troubleshooting to ensure optimal equipment performance.

3. Process Monitoring and Control

Monitoring the dough mixing process is crucial to ensure quality.

- Monitor dough temperature, mixing time, and consistency during the mixing process.

- Make adjustments to equipment settings or ingredients as needed to achieve desired results.

4. Quality Assurance

You will be responsible for ensuring the quality of the lozenge dough.

- Inspect dough samples visually and physically to assess quality.

- Follow established quality control procedures and standards.

Interview Tips

To ace your interview for a Lozenge Dough Mixer position, follow these tips:

1. Research the Company and Position

Thoroughly research the company’s products, industry, and values. Familiarize yourself with the specific requirements of the Lozenge Dough Mixer position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in lozenge dough preparation or similar manufacturing processes. Showcase your proficiency in operating and maintaining dough mixing equipment.

3. Quantify Your Accomplishments

When describing your experience, use specific numbers and metrics to quantify your accomplishments. For example, highlight the percentage improvement in dough consistency or the reduction in equipment downtime.

4. Prepare for Technical Questions

Be prepared to answer technical questions about lozenge dough mixing, such as the different types of ingredients used, the factors affecting dough consistency, and troubleshooting techniques.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and knowledge of the industry. This could include questions about the company’s production processes or the latest advancements in lozenge dough mixing technology.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lozenge Dough Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!