Feeling lost in a sea of interview questions? Landed that dream interview for Lube Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Lube Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

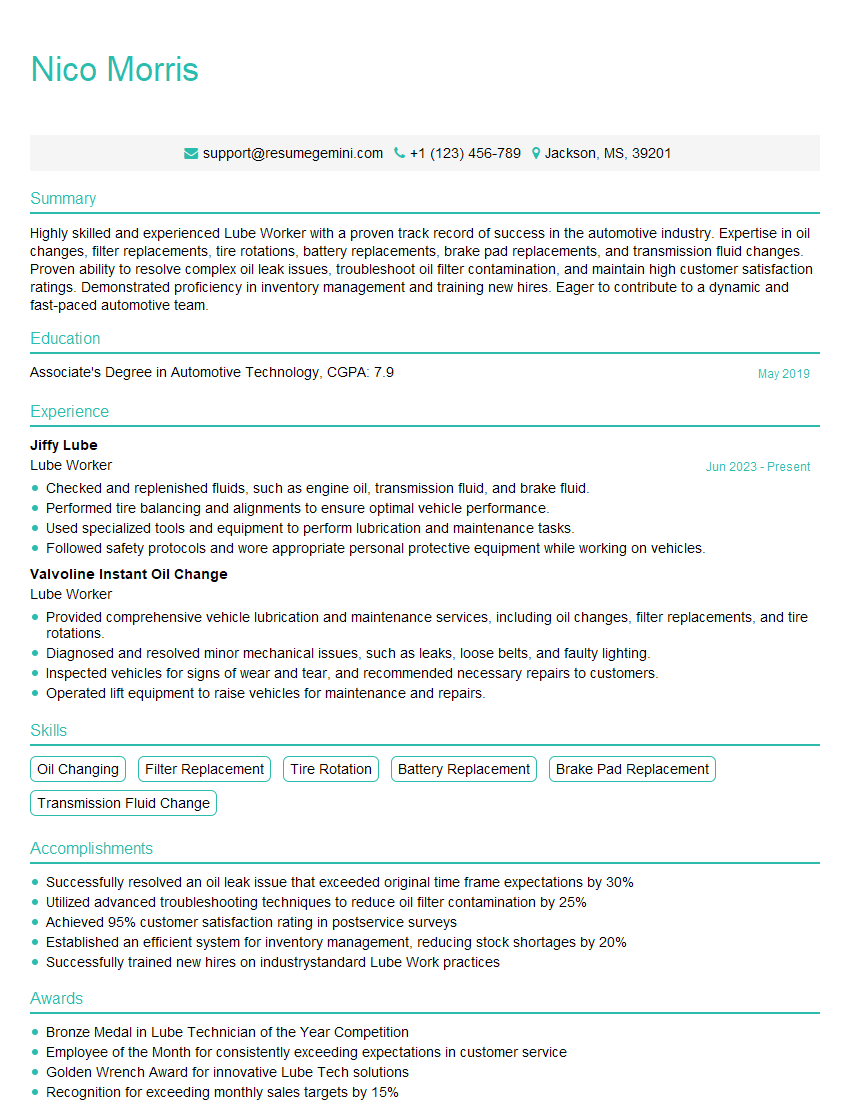

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lube Worker

1. What are the most important safety precautions you take when working as a Lube Worker?

As a Lube Worker, safety is paramount. I strictly adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and coveralls.

- Maintain a clean and organized work area, free of tripping hazards and spills.

- Handle hazardous materials, such as oil and chemicals, with care and follow proper disposal procedures.

- Operate machinery and equipment safely, following established protocols and receiving necessary training.

- Report any unsafe conditions or potential hazards immediately to a supervisor.

2. How do you ensure that you are using the correct type and amount of lubricant for each vehicle?

Technical Expertise

- Consult and thoroughly understand the vehicle manufacturer’s lubrication specifications.

- Identify the proper lubricant type (e.g., oil weight, viscosity) and quantity for each make and model.

- Use precise measuring tools to dispense the exact amount of lubricant required.

Attention to Detail

- Double-check the lubricant type and quantity against the vehicle’s specifications.

- Inspect the lubrication points carefully to ensure they are clean and free of obstructions.

- Document all lubrication services performed, including the lubricant used and the amount applied.

3. What are some common signs that a vehicle may need lubrication?

I pay attention to various signs that indicate a vehicle may require lubrication:

- Unusual noises or vibrations, such as squeaks, grinding, or chattering, particularly during steering or acceleration.

- Stiff or sluggish operation of moving parts, including steering, suspension, or brakes.

- Visible leaks or drips of lubricant from components or seals.

- Excessively high or low fluid levels in the vehicle’s lubrication system (e.g., engine oil, transmission fluid).

- Extended periods of operation without proper lubrication maintenance.

4. How do you troubleshoot and resolve lubrication-related problems?

To troubleshoot lubrication-related problems, I follow a systematic approach:

- Identify the symptoms or issue reported by the customer or observed during inspection.

- Inspect the lubrication points, components, and fluid levels to locate the source of the problem.

- Determine the type and amount of lubricant required to address the issue.

- Lubricate the affected components as necessary, ensuring proper application techniques.

- Monitor the vehicle’s performance after lubrication to verify the resolution of the problem.

5. How do you handle customer inquiries or concerns related to lubrication services?

Communication and Customer Service

- Listen attentively to the customer’s concerns and ask clarifying questions to fully understand their issue.

- Provide clear and concise explanations about the lubrication services performed or recommended.

- Address any concerns professionally and offer solutions to resolve any dissatisfaction.

Technical Proficiency

- Explain the benefits and importance of regular lubrication based on technical knowledge and industry best practices.

- Recommend appropriate lubrication services tailored to the customer’s vehicle and driving habits.

- Provide documentation and warranties for lubrication services performed, as required.

6. How do you maintain and calibrate the equipment used in lubrication services?

To ensure accurate and efficient lubrication services, I meticulously maintain and calibrate the equipment:

- Follow established maintenance schedules for lubrication equipment and tools.

- Inspect and clean equipment regularly to prevent malfunctions and ensure optimal performance.

- Calibrate equipment according to manufacturer’s specifications using precise measuring devices.

- Document maintenance and calibration records to maintain traceability and compliance.

- Report any equipment issues or malfunctions promptly to ensure timely repairs or replacements.

7. What is your understanding of different types of lubricants and their applications?

I possess a comprehensive understanding of various types of lubricants and their specific applications:

- Engine oils: Designed to lubricate moving parts within the engine, protect against wear and tear, and enhance engine performance.

- Transmission fluids: Used to lubricate gears and bearings in transmissions, ensuring smooth shifting and power transfer.

- Brake fluids: Essential for hydraulic brake systems, transmitting pressure to actuate the brakes and preventing corrosion.

- Power steering fluids: Aid in steering systems, reducing friction, and assisting in turning maneuvers.

- Specialty lubricants: Tailored for specific applications, such as high-temperature or extreme-pressure conditions.

8. How do you stay updated with the latest developments and best practices in lubrication techniques?

To maintain my technical proficiency and stay abreast of industry advancements, I engage in the following practices:

- Attend training sessions and workshops conducted by lubricant manufacturers and industry experts.

- Read industry publications, technical articles, and online resources to expand my knowledge.

- Seek guidance and mentorship from experienced Lube Workers or supervisors.

- Participate in online forums and discussions to share knowledge and learn from others.

- Stay informed about new lubrication products, technologies, and industry regulations.

9. How do you organize and prioritize your daily workload as a Lube Worker?

Time Management

- Plan and prioritize tasks based on urgency and importance to ensure timely completion.

- Break down large tasks into smaller, manageable steps to improve efficiency.

- Use a checklist or schedule to track progress and stay organized.

Adaptability

- Adjust work schedule and priorities as needed to accommodate unexpected tasks or customer requests.

- Stay flexible and responsive to changing workloads and deadlines.

10. How do you ensure the cleanliness and organization of the lubrication work area?

Maintaining a clean and organized work area is crucial for efficient and safe operations. I adhere to the following practices:

- Regularly clean and disinfect work surfaces, tools, and equipment to prevent contamination.

- Properly store and dispose of used lubricants, filters, and other waste materials to maintain environmental compliance.

- Organize tools and supplies in designated areas to facilitate easy access and reduce clutter.

- Conduct routine inspections to identify and address any potential hazards or spills.

- Encourage a culture of cleanliness and organization among colleagues to maintain a professional work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lube Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lube Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lube Workers are responsible for a variety of tasks that help keep vehicles running smoothly and efficiently. These responsibilities may include:

1. Performing oil changes

This involves draining the old oil from the engine, replacing the oil filter, and adding new oil. Oil changes are essential for preventing engine damage and prolonging the life of the vehicle.

2. Greasing chassis components

This helps to reduce friction and wear on moving parts, such as the suspension and steering components. It also helps to prevent rust and corrosion.

3. Changing tires

This is a critical safety task that ensures that the tires are properly inflated and in good condition. It also helps to prevent flats and blowouts.

4. Inspecting vehicles for potential problems

This can help to identify minor issues before they become major problems. It also helps to keep the vehicle running safely and efficiently.

5. Maintaining a clean and organized work area

This helps to ensure that the Lube Worker can work safely and efficiently. It also makes the work area more pleasant for customers.

Interview Tips

Interviewing for a Lube Worker position can be a nerve-wracking experience. However, by following these tips, you can increase your chances of making a good impression and landing the job.

1. Research the company and the position

This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company’s website, Glassdoor, and other online resources.

2. Practice your answers to common interview questions

This will help you to feel more confident and prepared during the interview. Some common interview questions for Lube Workers include:

- Tell me about your experience with performing oil changes.

- How do you ensure that the tires are properly inflated and in good condition?

- What are some of the challenges you have faced as a Lube Worker?

- How do you stay up-to-date on the latest automotive repair techniques?

- Why are you interested in working for our company?

3. Dress professionally

This shows that you are taking the interview seriously and that you are respectful of the interviewer’s time. You should wear clean, pressed clothes and avoid wearing any revealing or distracting clothing.

4. Be on time for your interview

Punctuality is important for any job interview, but it is especially important for a Lube Worker position. This shows that you are reliable and that you are respectful of the interviewer’s time.

5. Be enthusiastic and positive

Interviewers are more likely to hire candidates who are enthusiastic and positive about the position. This shows that you are genuinely interested in the job and that you are excited about the opportunity to work for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lube Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.