Are you gearing up for an interview for a Lubricating Specialist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lubricating Specialist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

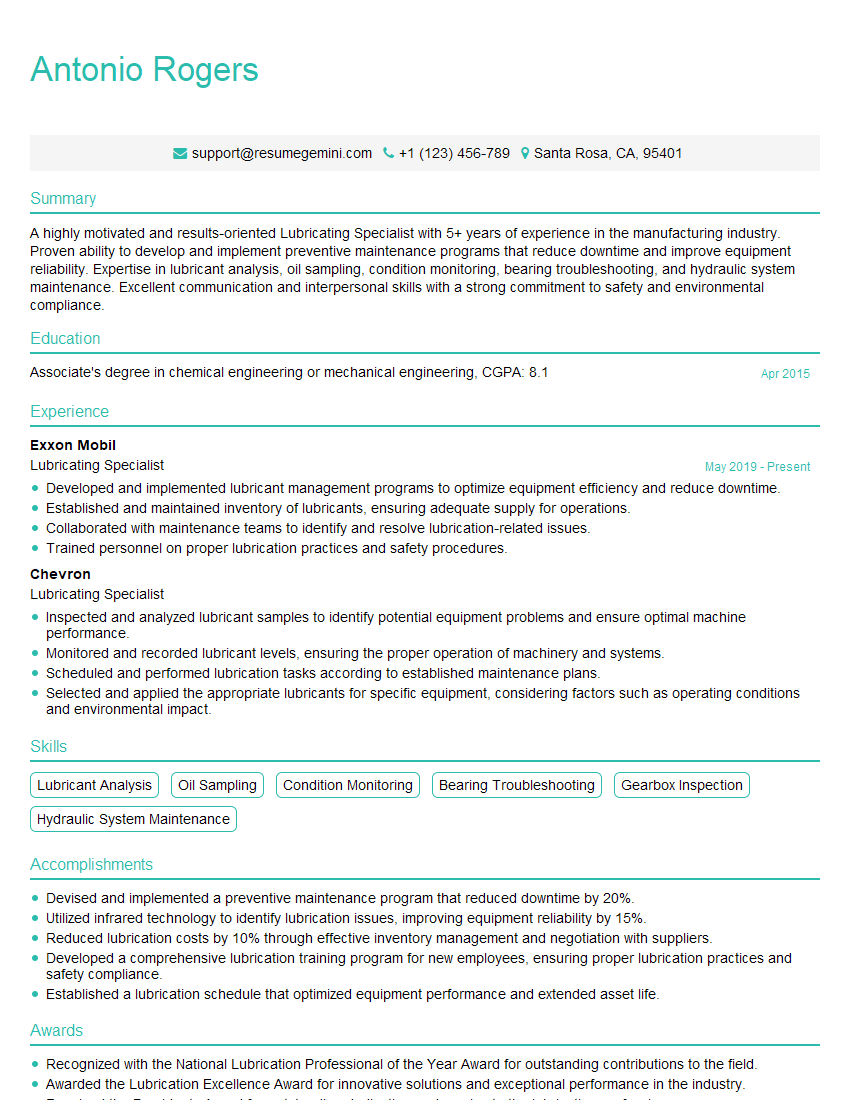

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubricating Specialist

1. How do you determine the correct lubricant for a specific application?

When determining the appropriate lubricant for a particular application, I consider various factors:

- Equipment Type and Operating Conditions: Understanding the equipment’s design, load, speed, and temperature range helps narrow down the lubricant options.

- Lubricant Specifications: Adhering to manufacturer’s recommendations and industry standards ensures compatibility and performance.

- Environmental Considerations: Lubricants must align with environmental regulations, such as biodegradability and sustainability.

2. Describe the key properties and performance characteristics of lubricating greases.

Consistency and Viscosity

- Consistency refers to the hardness or softness of the grease, affecting its ability to stay in place and withstand shear forces.

- Viscosity determines the grease’s resistance to flow, influencing its ability to lubricate moving surfaces effectively.

Additives

- Additives enhance lubricant performance, providing anti-wear, anti-oxidation, and extreme pressure protection.

Temperature Range

- Lubricating greases must withstand the temperature variations encountered in the application.

3. How do you monitor the condition of lubricants and determine when they need to be replaced?

Monitoring lubricant condition involves several techniques:

- Visual Inspection: Discoloration, sludge, or metal particles can indicate lubricant degradation.

- Oil Analysis: Tests conducted on lubricant samples provide insights into its physical and chemical properties.

- Maintenance Schedules: Regular lubricant replacement based on manufacturer recommendations ensures optimal performance and extends equipment life.

4. What are the different types of lubrication systems and their applications?

Lubrication systems vary based on the method of delivering lubricant to the components:

- Manual Lubrication: Applied manually using grease guns or oil cans for small-scale applications.

- Automatic Lubrication: Utilizes pumps, timers, or flow indicators to deliver lubricant automatically.

- Centralized Lubrication: A network of pipes and fittings distributes lubricant to multiple points from a central reservoir, ensuring consistent lubrication.

5. Describe the importance of proper lubrication for industrial machinery.

Proper lubrication is crucial for industrial machinery due to its numerous benefits:

- Reduces Friction and Wear: Lubricants create a protective film between moving parts, minimizing friction and preventing wear.

- Prevents Corrosion: Lubricants protect metal surfaces from rust and corrosion caused by moisture and contaminants.

- Extends Equipment Life: Regular and appropriate lubrication helps maintain optimal performance, increasing equipment lifespan.

- Improves Energy Efficiency: Reduced friction due to lubrication improves energy efficiency and lowers operating costs.

6. What are the emerging trends and advancements in lubrication technology?

Lubrication technology is evolving with innovative advancements:

- Bio-Based Lubricants: These environmentally friendly lubricants are derived from renewable resources, reducing environmental impact.

- Nano-Lubricants: Utilizing nanoparticles, these lubricants provide enhanced anti-wear and extreme pressure properties.

- Lubrication Sensors: Sensors integrated into lubrication systems monitor lubricant condition, enabling predictive maintenance.

7. How do you stay up-to-date with the latest developments in the lubrication industry?

To stay abreast of industry advancements, I actively engage in the following:

- Continuing Education: Attending conferences, webinars, and workshops to expand my knowledge and skills.

- Trade Publications and Journals: Subscribing to industry-specific publications to stay informed about research and best practices.

- Professional Organizations: Joining lubrication-related professional organizations for networking and knowledge sharing.

8. Describe a challenging lubrication issue you encountered and how you resolved it.

In a recent project, we faced an issue with premature bearing failure in a high-temperature application:

- Analysis and Investigation: I analyzed the failed bearing, lubricant properties, and operating conditions.

- Solution Identification: Determined that the lubricant’s viscosity was too low for the high temperatures, resulting in insufficient film thickness.

- Implementation: Recommended and implemented a lubricant with higher viscosity, suitable for the extreme temperature conditions.

- Monitoring and Evaluation: Monitored the bearing performance and confirmed reduced failure rates, validating the solution.

9. What safety precautions should be considered when working with lubricants?

Safety is paramount when handling lubricants:

- Material Safety Data Sheets (MSDS): Familiarizing myself with MSDSs to understand the potential hazards of lubricants.

- Personal Protective Equipment (PPE): Utilizing appropriate PPE, such as gloves, eye protection, and respirators, to minimize exposure.

- Proper Handling and Storage: Adhering to safe handling and storage practices to prevent spills, contamination, and fire hazards.

- Waste Disposal: Ensuring proper disposal of used lubricants and contaminated materials to minimize environmental impact.

10. How do you contribute to environmental sustainability in your role as a Lubricating Specialist?

Environmental sustainability is integral to my role:

- Lubricant Selection: Prioritizing bio-based and environmentally friendly lubricants to reduce environmental impact.

- Lubricant Management: Implementing programs to optimize lubricant usage, minimize waste, and extend lubricant life.

- Collaboration with Suppliers: Working with suppliers to explore and adopt sustainable lubricant solutions.

- Awareness and Training: Educating colleagues and customers on the importance of environmental sustainability in lubrication practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubricating Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubricating Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubricating Specialists play a vital role in maintaining the smooth operation and longevity of machinery and equipment across various industries. Their key responsibilities include:

1. Lubrication Management

Developing and implementing lubrication schedules to ensure optimal lubrication of machinery and equipment.

- Selecting and applying appropriate lubricants based on equipment specifications and operating conditions.

- Monitoring and adjusting lubrication intervals to extend equipment lifespan and prevent breakdowns.

2. Equipment Maintenance

Inspecting and maintaining equipment to identify potential lubrication issues and prevent failures.

- Performing visual inspections, oil sampling, and other diagnostic tests to assess lubrication quality and equipment condition.

- Making necessary repairs and adjustments to lubrication systems, such as replacing filters, hoses, and seals.

3. Troubleshooting and Problem Solving

Diagnosing and resolving lubrication-related problems to minimize downtime and ensure equipment efficiency.

- Analyzing equipment performance data, identifying patterns, and isolating root causes of issues.

- Recommending corrective actions, implementing solutions, and verifying their effectiveness.

4. Training and Supervision

Providing training and guidance to maintenance staff on proper lubrication practices and procedures.

- Developing and delivering training programs on lubrication theory, best practices, and safety protocols.

- Supervising lubrication technicians, ensuring adherence to established standards and safety guidelines.

Interview Tips

To ace the interview for a Lubricating Specialist position, it is crucial to prepare thoroughly and showcase your knowledge and skills. Here are some interview tips and hacks to help you succeed:

1. Research the Industry and Company

Before the interview, research the lubrication industry, the company you are applying to, and the specific role you are seeking. This will help you understand the company’s culture, challenges, and expectations.

- Visit the company’s website to gather information about their products, services, and recent news.

- Read industry publications and articles to stay up-to-date on current trends and best practices.

2. Quantify Your Experience

When describing your experience, use specific numbers and data to quantify your accomplishments. This will make your achievements more tangible and impressive to the interviewer.

- Instead of saying “I improved lubrication practices,” say “I implemented a new lubrication schedule that reduced equipment downtime by 15%.”

- Provide specific examples of how your actions led to measurable results.

3. Highlight Your Technical Skills

Lubrication Specialists are expected to possess strong technical skills. Highlight your expertise in equipment maintenance, lubrication analysis, and problem-solving during the interview.

- Discuss your experience using specific lubrication tools and equipment.

- Provide examples of how you have successfully diagnosed and resolved lubrication-related issues.

4. Emphasize Your Safety Awareness

Safety is paramount in any industrial setting, including lubrication. Emphasize your commitment to safety and your understanding of proper lubrication practices to minimize risks.

- Describe your experience adhering to safety regulations and protocols.

- Explain how you ensure the safe handling, storage, and disposal of lubricants and hazardous materials.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Lubricating Specialist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.