Are you gearing up for an interview for a Lubrication Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lubrication Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

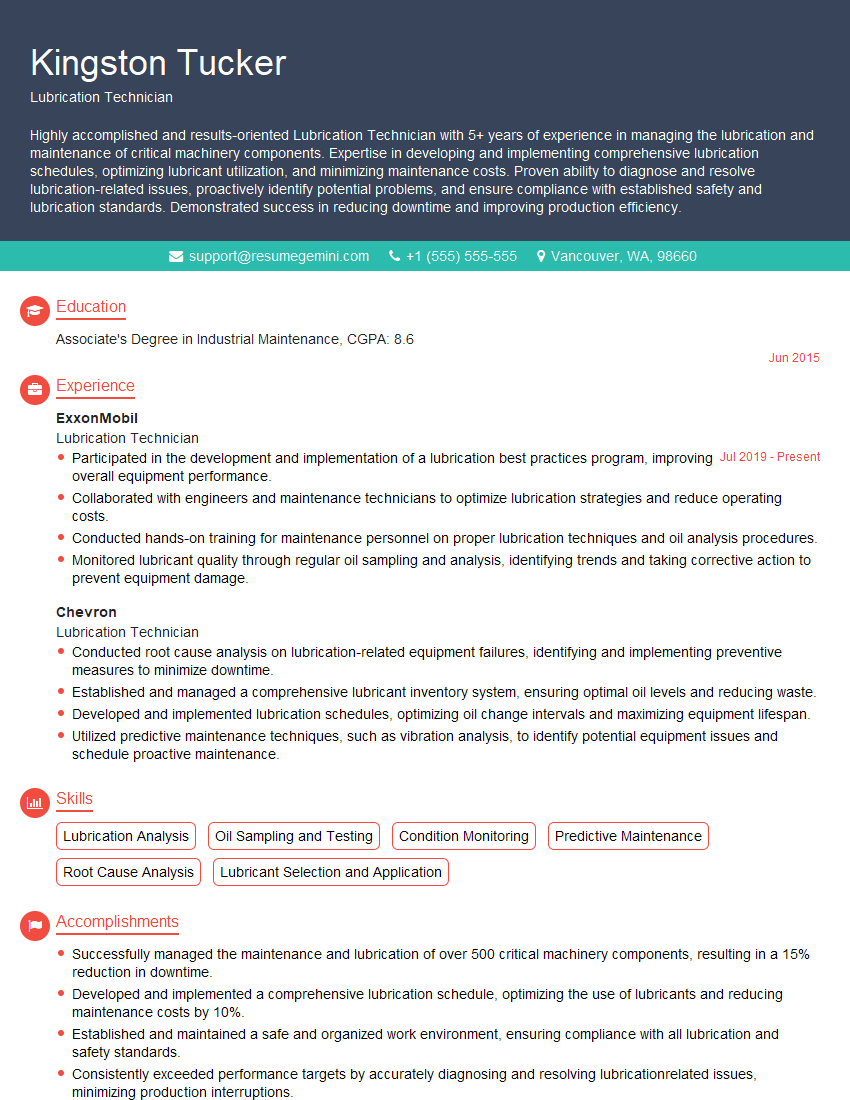

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubrication Technician

1. What are the key responsibilities of a Lubrication Technician?

- Lubricate machinery and equipment to prevent wear and tear and ensure smooth operation.

- Monitor and maintain lubrication systems, including oil and grease levels, to ensure optimal performance.

- Analyze oil samples to identify wear, contamination, and other potential issues.

- Troubleshoot and resolve lubrication-related problems.

- Maintain and calibrate lubrication equipment, such as grease guns, oil dispensers, and oil filtration systems.

- Follow safety procedures and environmental regulations related to lubrication and hazardous materials.

- Adhere to quality assurance standards and documentation requirements.

2. Describe the different types of lubricants used in industrial settings and their applications.

Oils

- Mineral oils

- Synthetic oils

- Bio-based oils

Greases

- Mineral greases

- Synthetic greases

- Specialty greases (e.g., high temperature, low friction)

Other Lubricants

- Solid lubricants (e.g., graphite, molybdenum disulfide)

- Dry lubricants (e.g., PTFE coatings)

- Specialty lubricants (e.g., food-grade, extreme pressure lubricants)

3. Explain the importance of lubrication in maintaining the efficiency and lifespan of machinery.

- Reduces friction and wear

- Cools and dissipates heat

- Prevents corrosion and contamination

- Improves energy efficiency

- Extends the lifespan of equipment

- Ensures smooth operation and minimizes downtime

4. What are the common signs and symptoms of inadequate lubrication?

- Increased noise and vibration

- Elevated temperatures

- Abnormal wear

- Power loss

- Reduced efficiency

- Premature failure

5. Describe the steps involved in developing and implementing a lubrication program.

- Assess machinery and lubrication needs

- Select appropriate lubricants

- Determine lubrication frequency and methods

- Establish lubrication routes and schedules

- Train personnel on lubrication procedures

- Monitor and evaluate lubrication program effectiveness

- Make adjustments and improvements as needed

6. What are the safety precautions that must be observed when working with lubricants?

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses, respirators)

- Handle and store lubricants properly

- Avoid skin contact with lubricants

- Dispose of used lubricants and rags in accordance with environmental regulations

- Be aware of potential hazards, such as spills, leaks, and fires

7. What are the latest trends and technologies in the field of lubrication?

- Synthetic lubricants

- Bio-based lubricants

- Solid and dry lubricants

- Automated lubrication systems

- Condition monitoring and predictive maintenance

- Lubrication software and data analytics

8. How do you stay up-to-date on industry best practices for lubrication?

- Attend industry conferences and webinars

- Read trade journals and technical publications

- Network with other lubrication professionals

- Participate in professional development programs

- Follow industry standards and guidelines

9. What is your approach to problem-solving when it comes to lubrication-related issues?

- Gather information and diagnose the problem

- Identify potential causes and solutions

- Evaluate and select the best solution

- Implement the solution and monitor its effectiveness

- Make necessary adjustments and improvements

10. Can you tell me about a particularly challenging lubrication problem you encountered and how you resolved it?

- Describe the problem in detail

- Explain the steps you took to diagnose the problem

- Discuss the solutions you considered and why you chose the one you did

- Describe how you implemented the solution and monitored its effectiveness

- Explain what you learned from the experience

11. How do you prioritize lubrication tasks in a busy industrial environment?

- Critical equipment

- Time-sensitive tasks

- Safety concerns

- Lubrication frequency and intervals

- Availability of resources

12. What is your experience with lubrication software and data analytics?

- Specific software programs or tools used

- Benefits and challenges of using lubrication software

- How data analytics improves lubrication practices

- Examples of how you have used lubrication software or data analytics in the past

13. How do you handle situations where you need to troubleshoot complex lubrication systems?

- Logical troubleshooting approach

- Use of diagnostic tools and testing equipment

- Consultation with experts or manufacturers

- Review of maintenance records and schematics

- Safety considerations and risk assessment

14. What are your strengths and weaknesses as a Lubrication Technician?

Strengths

- Expertise in lubrication principles and practices

- Strong technical skills and problem-solving abilities

- Excellent attention to detail and a high level of accuracy

- Proficient in using lubrication equipment and software

Weaknesses

- Limited experience with certain specialized lubrication systems

- Working in confined spaces or at heights can be a challenge

- Balancing multiple tasks and prioritizing lubrication activities

15. Why are you interested in this Lubrication Technician position?

- Passion for maintaining and optimizing machinery through effective lubrication

- Desire to contribute to the smooth operation and efficiency of industrial processes

- Opportunity to apply my skills and knowledge to real-world applications

- Alignment with the company’s commitment to equipment reliability and safety

- Potential for professional growth and development in the field of lubrication

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubrication Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubrication Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubrication Technicians are responsible for performing various lubrication and maintenance tasks to ensure smooth and efficient operation of equipment and machinery in different areas.

1. Lubrication and Maintenance

Lubrication technicians apply lubricants such as oils, greases, and other fluids to moving parts and equipment to reduce friction and wear, and to prevent breakdowns.

- Selecting appropriate lubricants based on equipment specifications and operating conditions

- Manually or automatically applying lubricants to machinery and components

2. Equipment Inspection and Monitoring

Inspect and monitor machinery and equipment regularly to identify and address potential issues, and to ensure proper functioning and lubrication.

- Inspecting equipment for wear, damage, or any signs of malfunction

- Using instruments and tools to monitor lubrication levels and fluid conditions

3. Maintenance and Repair

Perform minor repairs and maintenance tasks on lubricated equipment, such as adjusting or replacing components, to maintain optimal performance.

- Replacing worn or damaged parts, such as bearings, seals, and filters

- Adjusting and aligning equipment for proper operation

4. Record Keeping and Reporting

Maintain accurate records of lubrication activities, including the type of lubricant used, quantity applied, and dates of service. Provide reports and recommendations to management on lubrication-related issues.

- Maintaining detailed logs and records of lubrication schedules and activities

- Reporting any lubrication deficiencies or equipment concerns to supervisors

Interview Tips

Preparing for a lubrication technician interview requires a good understanding of the job’s responsibilities, as well as general interview best practices. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, research the company and the specific lubrication technician role. Familiarize yourself with the company’s size, industry, products or services, and company culture. Also, carefully review the job description to understand the key responsibilities and requirements for the position.

- Visit the company’s website and social media pages

- Read industry news and articles related to the company

2. Practice Answering Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Think about your experiences and skills, and prepare specific examples that highlight your qualifications for the job.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Emphasize your technical skills, experience with different types of equipment, and knowledge of lubrication best practices

3. Highlight Your Technical Skills and Experience

In the interview, clearly showcase your technical skills and experience in lubrication. Discuss your knowledge of different types of lubricants, lubrication systems, and maintenance procedures. Mention any specific equipment or industries you have experience with.

- Quantify your accomplishments to provide concrete evidence of your skills

- Use industry-specific terminology and concepts to demonstrate your knowledge

4. Show Enthusiasm and a Positive Attitude

Throughout the interview, maintain a positive and enthusiastic attitude. Express your interest in the role and the company, and be prepared to share why you are passionate about lubrication and maintenance.

- Be professional and courteous, and dress appropriately

- Be confident in your abilities, but avoid being overly aggressive

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lubrication Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!