Feeling lost in a sea of interview questions? Landed that dream interview for Macerator Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Macerator Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

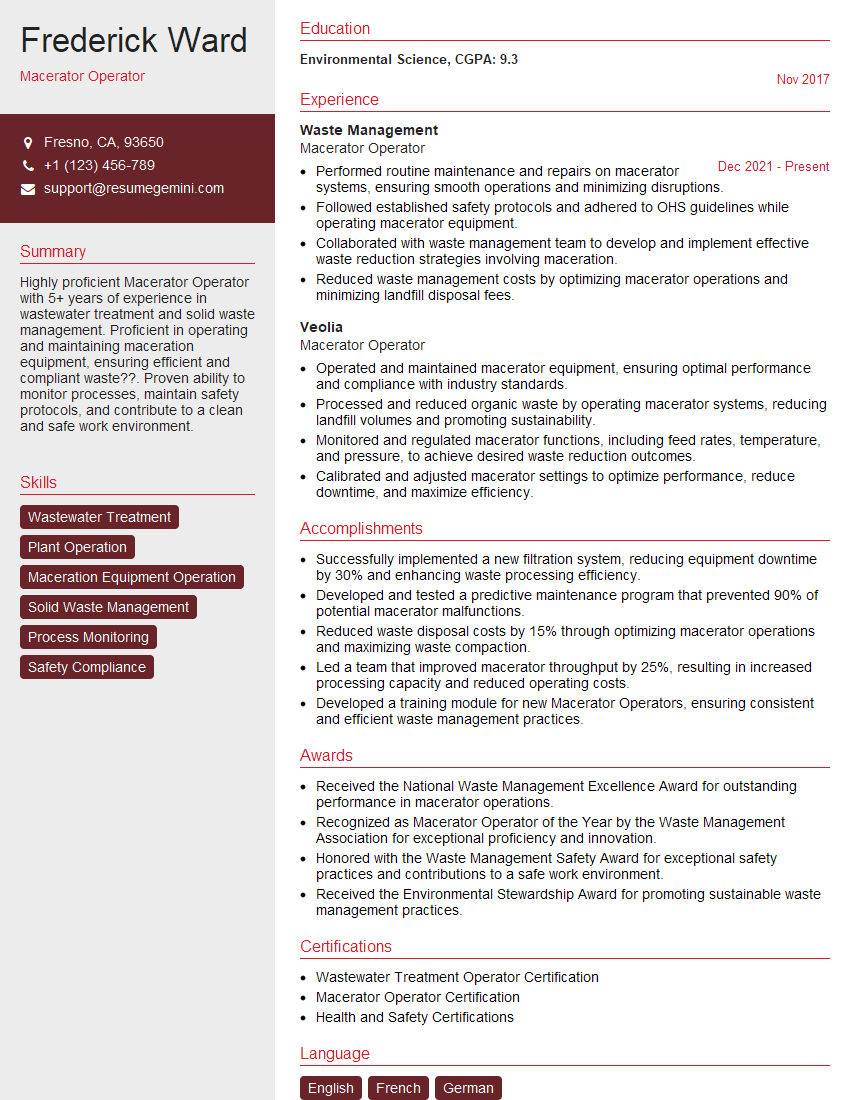

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Macerator Operator

1. What are the key responsibilities of a Macerator Operator?

- Monitor and operate macerator equipment to grind and reduce solid materials into smaller particles.

- Ensure that macerated materials meet the required size and consistency specifications.

- Perform routine maintenance and inspections on macerator equipment, including cleaning and replacing parts as necessary.

- Troubleshoot and resolve any operational issues with the macerator system.

- Follow established safety protocols and procedures to ensure a safe working environment.

- Maintain accurate records of macerator operations and any incidents or maintenance activities.

2. How do you handle blockages or jams in the macerator?

Troubleshooting and Resolution

- Stop the macerator and disconnect the power supply.

- Identify the location of the blockage or jam.

- Use appropriate tools or techniques to clear the obstruction, such as a wrench or a screwdriver.

Preventive Measures

- Regularly inspect and clean the macerator to prevent buildup of materials.

- Feed materials into the macerator gradually and avoid overloading it.

- Use a screen or filter to remove large or hard objects before they enter the macerator.

3. What types of materials can be macerated, and what are the limitations?

- Maceratable Materials:

- Organic materials: Food waste, paper, cardboard, yard waste

- Textiles: Clothing, rags

- Plastics: Thin plastics, packaging materials

- Limitations:

- Metals

- Glass

- Batteries

- Electronics

- Large or bulky items

4. How do you ensure that the macerated materials meet the desired consistency?

- Adjust the macerator’s settings and operating parameters, such as blade speed and feed rate.

- Monitor the output of the macerator and make adjustments as needed to achieve the desired particle size.

- Use sieves or screens to separate macerated materials based on size and consistency.

- Conduct regular quality checks and maintain accurate records to ensure ongoing consistency.

5. What are the safety precautions that must be taken when operating a macerator?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Never operate a macerator that is not properly grounded.

- Keep hands and loose clothing away from moving parts.

- Do not attempt to clear blockages or jams while the macerator is running.

- Follow established lockout/tagout procedures when performing maintenance or repairs.

- Be aware of potential hazards, such as electrical shock, mechanical failure, and chemical spills.

6. How do you maintain and troubleshoot a macerator?

Maintenance

- Regularly clean and inspect the macerator.

- Lubricate moving parts according to the manufacturer’s instructions.

- Replace worn or damaged parts promptly.

Troubleshooting

- Refer to the manufacturer’s manual for specific troubleshooting procedures.

- Identify the symptoms of the problem and check for common causes, such as blockages, electrical issues, or mechanical failures.

- Use appropriate tools and techniques to diagnose and resolve the problem safely.

7. What are the environmental considerations related to macerator operations?

- Proper disposal of macerated materials to avoid contamination or pollution.

- Minimizing noise and vibration to comply with environmental regulations.

- Using energy-efficient macerators and implementing sustainable practices to reduce the environmental impact.

- Adhering to waste management regulations and following best practices for environmental protection.

8. What is your understanding of the latest advancements in macerator technology?

- Improved blade designs for enhanced efficiency and durability.

- Advanced control systems for precise operation and automation.

- Integration of sensors and monitoring devices for real-time data collection and analysis.

- Development of self-cleaning macerators to reduce maintenance requirements.

- Focus on sustainable designs that prioritize energy efficiency and environmental protection.

9. How do you handle and dispose of macerated materials?

- Methods of Disposal:

- Landfill

- Composting

- Incineration

- Considerations:

- Environmental regulations and waste management guidelines

- Type and volume of macerated materials

- Availability of disposal facilities and transportation options

- Cost-effectiveness and sustainability

10. How would you approach a situation where the macerator is experiencing excessive vibrations?

Troubleshooting

- Check the macerator’s mounting and ensure it is securely fastened.

- Inspect the blades for any imbalances or damage.

- Examine the bearings and lubrication system to identify potential issues.

- Monitor the feed rate and adjust it to reduce strain on the macerator.

Resolution

- Tighten loose bolts or replace damaged mounting hardware.

- Rebalance or replace the blades.

- Lubricate the bearings and ensure proper operation.

- Adjust the feed rate to prevent overloading and excessive vibrations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Macerator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Macerator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Macerator Operator is responsible for the safe and efficient operation of maceration equipment. This includes:

1. Equipment Operation and Maintenance

• Operating macerators to process and reduce the size of various materials.

• Monitoring macerators during operation and making necessary adjustments to ensure efficient performance.

• Conducting regular maintenance and repairs on macerators to ensure optimal functionality.

2. Material Handling

• Loading materials into macerators and ensuring they are processed properly.

• Removing processed materials from macerators and disposing of them or recycling them as appropriate.

• Maintaining a clean and organized work area.

3. Health and Safety

• Following established safety protocols and procedures when operating macerators.

• Wearing appropriate personal protective equipment (PPE) to minimize exposure to hazards.

• Reporting any accidents or near-misses to supervisors immediately.

4. Other Responsibilities

• Keeping accurate records of macerator operations and maintenance activities.

• Working with other team members to achieve production goals.

• Maintaining a positive attitude and willingness to learn.

Interview Tips

To prepare for a Macerator Operator interview, it’s essential to:

1. Research the Company and Position

• Visit the company’s website to learn about its products, services, and culture.

• Read the job description thoroughly to understand the specific duties and responsibilities of the Macerator Operator role.

2. Practice Answering Common Interview Questions

• Prepare for questions about your experience with macerators, material handling, and safety procedures.

• Practice answering questions about your teamwork skills, problem-solving abilities, and attention to detail.

3. Highlight Your Skills and Experience

• In your resume and interview answers, emphasize your relevant skills and experience in maceration operations.

• Quantify your accomplishments whenever possible to demonstrate your impact.

4. Show Enthusiasm and Motivation

• Express your passion for working with macerators and your desire to learn more about the industry.

• Share examples of how you have gone above and beyond in previous roles.

5. Prepare Questions for the Interviewer

• Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position.

• Prepare questions about the company’s safety protocols, training opportunities, and growth potential for the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Macerator Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.