Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Bender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Bender so you can tailor your answers to impress potential employers.

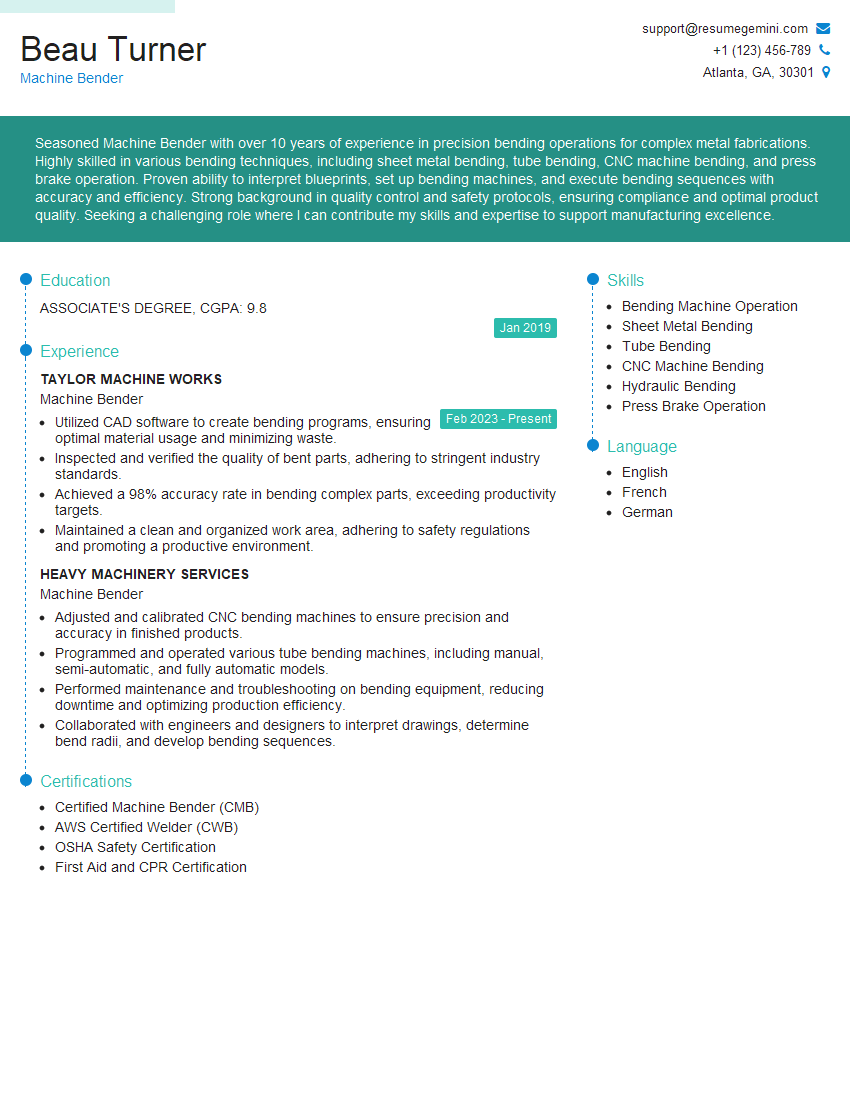

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Bender

1. What are the different types of machine bending processes?

- Rotary draw bending

- Three-roll bending

- Air bending

- Roll bending

2. What are the factors to consider when choosing a machine bending process?

Material thickness

- Thicker materials require more force and a different bending process.

Material type

- Different materials have different bending properties.

Bend radius

- The bend radius must be achievable with the chosen process.

Production volume

- The bending process must be able to meet the production requirements.

3. What are the advantages and disadvantages of different machine bending processes?

Rotary draw bending

Advantages

- High precision

- Can bend complex shapes

Disadvantages

- Slow

- Expensive

Three-roll bending

Advantages

- Fast

- Inexpensive

Disadvantages

- Not as precise as rotary draw bending

- Can’t bend complex shapes

Air bending

Advantages

- Fast

- Inexpensive

- Can bend a variety of materials

Disadvantages

- Not as precise as rotary draw bending or three-roll bending

Roll bending

Advantages

- Can bend long pieces of material

- Produces a consistent bend

Disadvantages

- Slow

- Expensive

4. What are the common problems that occur during machine bending?

- Springback

- Wrinkling

- Tearing

- Buckling

5. How can these problems be prevented or corrected?

Springback

- Use a smaller bend radius

- Overbend the material

- Use a springback allowance

Wrinkling

- Use a larger bend radius

- Use a wipe die

- Anneal the material

Tearing

- Use a sharper bend radius

- Use a thicker material

- Anneal the material

Buckling

- Use a larger bend radius

- Use a thicker material

- Use a support die

6. What are the safety precautions that must be followed when operating a machine bender?

- Wear appropriate safety gear

- Keep hands and feet clear of the bending area

- Do not overload the machine

- Follow the manufacturer’s instructions

7. What are the maintenance procedures that must be performed on a machine bender?

- Lubricate the machine regularly

- Check the machine for wear and tear

- Calibrate the machine regularly

- Follow the manufacturer’s maintenance instructions

8. What are the different types of materials that can be bent on a machine bender?

- Steel

- Aluminum

- Stainless steel

- Copper

- Brass

9. What are the different types of bends that can be made on a machine bender?

- 90-degree bends

- 180-degree bends

- U-bends

- V-bends

- Channel bends

10. What are the different types of tooling that can be used on a machine bender?

- Dies

- Punches

- Clamps

- Wipes

- Support dies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Benders play a pivotal role in the manufacturing industry by utilizing specialized equipment to transform metal sheets and rods into various shapes and components. Their key responsibilities include:

1. Machine Operation and Maintenance

Operate and maintain a variety of bending machines, such as press brakes, tube benders, and wire benders.

- Set up and calibrate machines according to specifications.

- Monitor and adjust machine settings throughout operation.

- Perform regular maintenance and troubleshooting to ensure optimal performance.

2. Material Handling and Preparation

Handle and prepare raw materials for bending processes.

- Inspect materials for defects and ensure they meet specifications.

- Cut, straighten, and clean materials as required.

- Load materials onto machines and unload finished parts.

3. Bending and Forming

Bend, shape, and form metal sheets and rods using specialized machines.

- Follow blueprints and technical drawings to achieve desired shapes and dimensions.

- Adjust machine settings to produce bends with accurate angles and radii.

- Inspect finished parts to ensure they meet quality standards.

4. Quality Control and Inspection

Perform quality control checks and inspections throughout the bending process.

- Measure and verify dimensions of finished parts using precision instruments.

- Identify and correct any deviations from specifications.

- Maintain records and document inspection results.

Interview Preparation Tips

To ace an interview for a Machine Bender position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific products or services. Research the job description thoroughly to understand the key responsibilities and requirements.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in machine operation, material handling, bending techniques, and quality control. Provide specific examples of your accomplishments and the impact you made.

4. Showcase your Attention to Detail

Machine Benders are known for their attention to detail. Highlight your ability to follow specifications precisely, identify errors, and produce high-quality parts.

5. Be Prepared to Discuss Technical Questions

Expect technical questions related to bending machines, materials, and processes. Review basic machine principles and different types of bending techniques.

6. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving on time for your interview. This shows respect for the interviewer and conveys your commitment to the position.

7. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your interest in the role and the company, and gives you an opportunity to clarify any information.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Bender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!