Are you gearing up for an interview for a Machine Loader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Machine Loader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

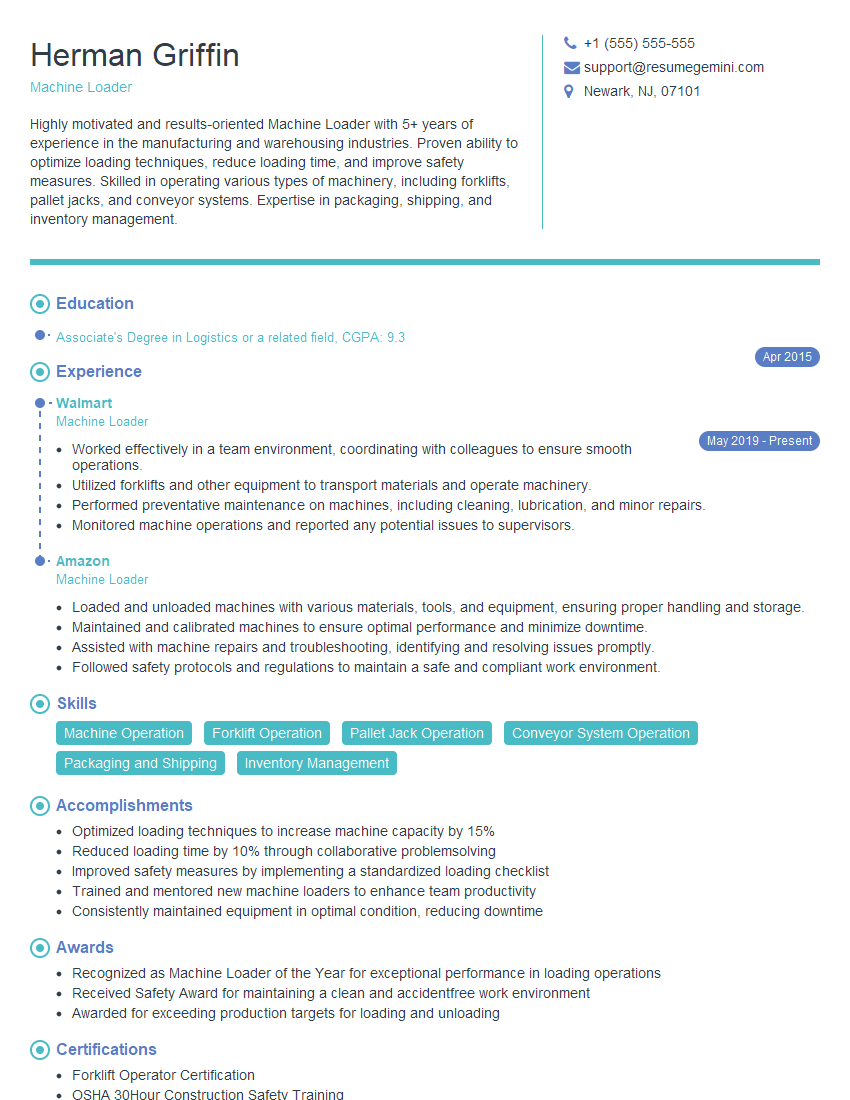

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Loader

1. Explain the process of loading and unloading materials using a machine loader?

The process of loading and unloading materials using a machine loader involves several key steps:

- Positioning the loader: The loader is positioned at the loading or unloading area, ensuring proper alignment with the truck or conveyor.

- Bucket operation: The loader’s bucket is extended and lowered to scoop up the material.

- Lifting and transporting: The bucket is raised and transported to the desired location.

- Unloading: The bucket is tilted or opened to discharge the material into the truck or conveyor.

- Bucket reset: The bucket is lowered and closed for the next cycle.

2. What factors influence the efficiency of a machine loader?

- Machine performance: The loader’s horsepower, bucket size, and hydraulic system affect its loading and unloading speed.

- Material characteristics: Factors such as material density, size, and shape influence the ease of loading and unloading.

- Operator skill: An experienced operator can optimize the loader’s performance and minimize cycle times.

- Environmental conditions: Weather, ground conditions, and visibility can impact the loader’s efficiency.

- Maintenance and repairs: Regular maintenance and timely repairs ensure optimal loader performance and minimize downtime.

3. How do you ensure safety when operating a machine loader?

Safety is paramount when operating a machine loader, and several measures are taken to ensure it:

- Pre-operation checks: Inspecting the loader’s controls, hydraulics, and bucket condition before operation.

- Proper training: Completing comprehensive training to understand the loader’s operation and safety procedures.

- Protective equipment: Wearing appropriate safety gear, including a hard hat, safety glasses, and high-visibility vest.

- Hazard awareness: Identifying potential hazards in the work area, such as overhead obstacles, slopes, and unstable ground.

- Following safety guidelines: Adhering to established industry standards and regulations for machine loader operation.

4. Describe the different types of attachments that can be used with a machine loader?

Machine loaders can be equipped with various attachments to enhance their functionality:

- Buckets: Different bucket sizes and shapes are available for specific applications, such as general loading, material handling, or excavation.

- Forks: Used to lift and transport pallets or other materials that require forks for stability.

- Grapples: Designed to handle irregular or heavy materials, such as logs, rocks, or scrap metal.

- Snow plows: Used to remove snow from roads, parking lots, and other surfaces.

- Brooms and brushes: Utilized for cleaning and sweeping floors, walkways, and other surfaces.

5. How do you troubleshoot common problems that occur with machine loaders?

Common problems with machine loaders and their troubleshooting steps include:

- Engine not starting: Check battery connections, fuel level, and spark plugs.

- Hydraulic system leaks: Inspect hoses, fittings, and cylinders for signs of damage or leaks.

- Bucket not operating: Verify hydraulic fluid levels, check for blockages in the hydraulic lines, and inspect the bucket’s cylinders.

- Loader overheating: Monitor coolant levels, check for radiator blockages, and ensure proper hydraulic fluid flow.

- Electrical system issues: Test batteries, wiring, and fuses to identify any faults.

6. Explain the importance of regular maintenance for machine loaders?

Regular maintenance is crucial for machine loaders to ensure:

- Optimal performance: Regular servicing helps maintain the loader’s performance and efficiency.

- Extended lifespan: Proper maintenance extends the loader’s lifespan by preventing premature wear and tear.

- Reduced downtime: Timely maintenance identifies and addresses potential issues, minimizing unscheduled downtime.

- Enhanced safety: Regular inspections help ensure the loader’s safety features and systems are functioning correctly.

- Warranty preservation: Adhering to maintenance schedules helps maintain the loader’s warranty coverage.

7. Describe the different types of machine loader controls?

Machine loaders utilize various types of controls:

- Lever controls: Traditional levers are used to operate the loader’s functions, such as boom movement, bucket tilt, and travel.

- Joystick controls: Joysticks provide intuitive and precise control over the loader’s hydraulic functions.

- Foot pedal controls: Foot pedals are often used for auxiliary functions, such as bucket shake or attachment control.

- Remote controls: Wireless or wired remote controls allow operators to operate the loader from a distance.

- Touchscreen controls: Advanced loaders may feature touchscreen displays for system monitoring and control.

8. What is the significance of load-sensing hydraulics in machine loaders?

Load-sensing hydraulics in machine loaders offer several key advantages:

- Improved efficiency: The system adjusts hydraulic pressure based on the load, reducing energy consumption.

- Enhanced control: Operators have better control over load handling and precise movements.

- Faster cycle times: The system responds quickly to load changes, enabling faster loading and unloading cycles.

- Reduced wear and tear: By matching hydraulic pressure to the load, the system reduces stress on components and extends their lifespan.

- Increased productivity: Overall, load-sensing hydraulics contribute to increased productivity and reduced operating costs.

9. How do you evaluate the performance of a machine loader?

Evaluating machine loader performance involves considering several key metrics:

- Cycle time: The time taken to complete a full loading or unloading cycle.

- Material throughput: The amount of material handled per unit of time.

- Fuel consumption: The amount of fuel used during operation.

- Maintenance costs: The costs incurred for regular maintenance and repairs.

- Operator feedback: Gathering insights from operators on the loader’s ease of use, comfort, and overall performance.

10. What are the career advancement opportunities for a Machine Loader?

With experience and additional training, Machine Loaders can advance their careers in various directions:

- Supervisor: Oversee a team of Machine Loaders, ensuring efficient operations and safety.

- Maintenance Technician: Specialize in maintaining and repairing machine loaders, diagnosing issues and performing necessary repairs.

- Equipment Operator Trainer: Train new Machine Loaders on proper operating techniques and safety protocols.

- Safety Manager: Develop and implement safety programs and procedures for machine loader operations.

- Fleet Manager: Manage a fleet of machine loaders, optimizing maintenance schedules and ensuring equipment availability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Loader is a crucial part of any manufacturing or production environment, responsible for loading and unloading materials into and out of machines, ensuring the smooth flow of operations. Key job responsibilities include:

1. Loading and Unloading Materials

The primary responsibility of a Machine Loader is to load and unload materials from machines, following specified instructions and procedures. This involves accurately placing and securing materials into the machine, and removing finished products or waste once the process is complete.

- Manually or using equipment, lift and move heavy materials, including raw materials, components, and finished products.

- Inspect materials for any defects or irregularities before loading into the machine.

2. Operating and Monitoring Machines

Machine Loaders may also be responsible for operating and monitoring certain types of machines. This includes starting, stopping, and adjusting machine settings to ensure optimal performance.

- Set up and operate machinery according to established procedures.

- Monitor machine performance, make adjustments as needed, and identify potential issues.

3. Maintaining Equipment

To prevent breakdowns and ensure efficient operations, Machine Loaders are often tasked with maintaining the equipment they work with. This involves routine cleaning, lubrication, and minor repairs.

- Perform basic maintenance and cleaning tasks to keep equipment in good working order.

- Report any equipment issues or malfunctions to supervisors for timely repairs.

4. Adhering to Safety Protocols

Working in a manufacturing environment requires strict adherence to safety protocols. Machine Loaders are responsible for following all established safety guidelines and procedures.

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

- Follow established safety procedures and regulations to minimize the risk of accidents or injuries.

Interview Tips

To ace an interview for a Machine Loader position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, culture, and the specific requirements of the Machine Loader role. This will help you tailor your answers and demonstrate your suitability for the job.

- Visit the company’s website and social media pages to gather information about their operations and values.

- Carefully review the job description and identify the key skills and qualifications they are seeking.

2. Practice Common Interview Questions

Prepare for commonly asked interview questions, such as those related to your experience, skills, and motivation. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and highlight your relevant experiences.

- Describe a situation where you successfully loaded and unloaded heavy materials under tight deadlines.

- Explain how you prioritize tasks and manage multiple responsibilities in a fast-paced environment.

3. Emphasize Safety and Attention to Detail

Safety is paramount in manufacturing environments. Highlight your commitment to adhering to safety protocols and your attention to detail in performing tasks. Provide examples of your safety practices and how you ensure accuracy in your work.

- Describe your experience with using personal protective equipment and following safety guidelines.

- Provide an example of a situation where your attention to detail led to the identification and resolution of a potential issue with equipment.

4. Showcase Physical Strength and Endurance

Machine Loaders often perform physically demanding tasks. During the interview, be prepared to discuss your physical strength and endurance. Share examples of your ability to lift and move heavy objects, and highlight your stamina for extended periods of work.

- Describe a time when you had to lift or move particularly heavy objects, and how you managed the task.

- Explain how you maintain your physical fitness and ensure you are able to meet the physical demands of the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Loader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.