Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Plaster Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

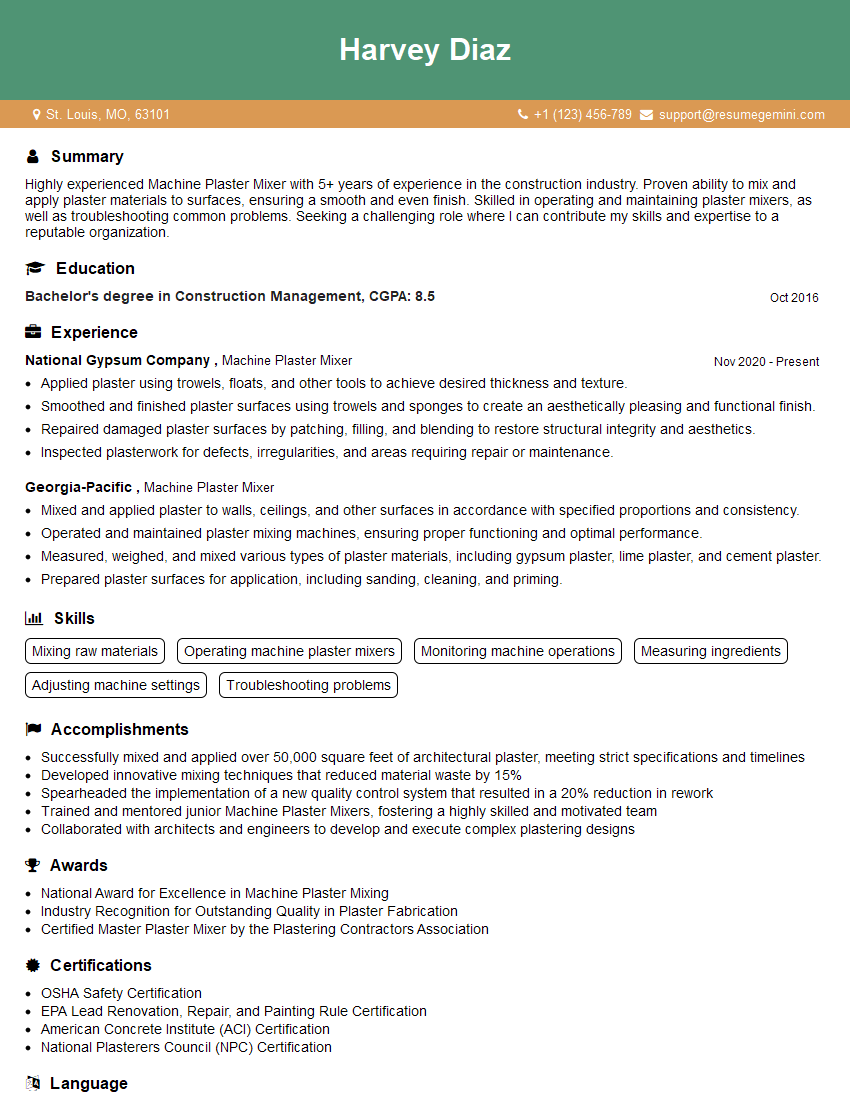

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Plaster Mixer

1. Describe the process of mixing plaster using a machine plaster mixer?

The process of mixing plaster using a machine plaster mixer involved several steps:

- Prepare the materials: Gather the necessary materials, including plaster powder, water, and any additives or pigments.

- Set up the mixer: Place the mixer in a suitable location and connect it to a power source.

- Add water to the mixer: Pour the required amount of water into the mixer’s drum.

- Add plaster powder to the mixer: Gradually add the plaster powder to the water while the mixer is running.

- Mix the plaster: Allow the mixer to run for the specified mixing time, ensuring that the plaster is thoroughly combined.

- Adjust consistency: If necessary, add more water or plaster powder to achieve the desired consistency.

- Unload the plaster: Once mixed, unload the plaster from the mixer into a suitable container.

2. Explain the different types of plaster used in construction and their applications?

Gypsum Plaster

- Versatile plaster used for interior wall and ceiling finishes.

- Suitable for both residential and commercial buildings.

- Provides a smooth, durable surface for painting or wallpapering.

Cement Plaster

- Stronger and more durable than gypsum plaster.

- Suitable for exterior walls and areas exposed to moisture.

- Often used as a base coat for tile or stone finishes.

Lime Plaster

- Traditional plaster with breathable properties.

- Suitable for historic buildings and renovations.

- Provides a distinctive, textured finish.

3. What are the key factors to consider when selecting a machine plaster mixer?

When selecting a machine plaster mixer, several key factors should be considered:

- Capacity: Determine the required mixing capacity based on the project scale and plaster quantity.

- Speed and efficiency: Choose a mixer with an appropriate mixing speed to ensure efficient and timely mixing.

- Portability and maneuverability: Consider the accessibility of the worksite and the ability to move the mixer easily.

- Reliability and durability: Ensure the mixer is well-built and reliable to withstand the demands of construction.

- Maintenance and availability of spare parts: Consider the maintenance requirements and the availability of spare parts to keep the mixer operational.

4. Describe the safety precautions to observe when operating a machine plaster mixer?

To ensure safety when operating a machine plaster mixer, several precautions should be observed:

- Wear appropriate safety gear: Including gloves, eye protection, and respiratory mask.

- Secure the mixer properly: Place the mixer on a stable surface and connect it to a grounded power source.

- Avoid overloading the mixer: Do not exceed the manufacturer’s recommended capacity to prevent accidents.

- Keep the work area clean: Clear away any spills or debris to maintain a safe work environment.

- Follow manufacturer’s instructions: Carefully read and follow the manufacturer’s instructions for safe operation and maintenance.

5. Explain how to troubleshoot common problems that may occur during plaster mixing?

During plaster mixing, common problems may include:

- Uneven mixing: Check the mixer blades and ensure they are properly aligned and rotating correctly.

- Improper consistency: Adjust the water or plaster powder ratio as needed to achieve the desired consistency.

- Clogged mixer: Clean the mixer drum and blades of any plaster buildup to prevent clogging and ensure smooth operation.

- Electrical issues: Check the power supply and ensure the mixer is properly connected and not overloaded.

- Excessive noise or vibration: Inspect the mixer for any loose parts or misalignment and address them promptly.

6. How do you ensure the quality of plaster mixed using a machine plaster mixer?

To ensure the quality of plaster mixed using a machine plaster mixer:

- Follow the manufacturer’s instructions: Use the recommended plaster powder and water ratios.

- Mix thoroughly: Allow the mixer to run for the specified mixing time to ensure a homogeneous mixture.

- Test the consistency: Perform consistency tests to ensure the plaster meets the required specifications.

- Monitor the mixing process: Observe the mixing process to identify any irregularities or problems.

- Clean the mixer regularly: Maintain the mixer by cleaning it after each use to prevent contamination.

7. Describe the maintenance procedures for a machine plaster mixer?

Regular maintenance is crucial for the optimal performance and longevity of a machine plaster mixer:

- Clean the mixer thoroughly: Clean the mixer drum, blades, and other components after each use.

- Lubricate moving parts: Apply lubricant to all moving parts as per the manufacturer’s instructions.

- Inspect the electrical system: Check the wiring, connections, and motor for any damage or wear.

- Tighten loose parts: Ensure all bolts, nuts, and screws are tightened securely.

- Store the mixer properly: Store the mixer in a dry, protected area when not in use.

8. What are the different types of plastering techniques used in construction?

- Float and set: A traditional method involving applying a base coat, followed by a smooth finishing coat.

- Drywalling: Using pre-fabricated gypsum boards to create wall and ceiling surfaces.

- Venetian plaster: A decorative technique creating a smooth, polished finish with multiple layers of plaster.

- Stucco: A durable, weather-resistant plaster used for exterior walls and surfaces.

- Lime render: A breathable, traditional plaster often used in historic buildings.

9. How do you handle and store plaster materials safely?

- Proper storage: Store plaster powder in a dry, moisture-free environment.

- Handling with care: Wear appropriate safety gear when handling plaster, as it can cause irritation.

- Disposal: Dispose of plaster waste properly according to local regulations.

10. Describe your experience in working with machine plaster mixers and any specific techniques you have developed?

Throughout my career, I have extensively used machine plaster mixers in various construction projects. I have developed specific techniques to enhance efficiency and quality:

- Optimizing mixing ratios: I have experimented with different plaster powder and water ratios to achieve optimal consistency and workability.

- Efficient mixing techniques: I utilize proper blade alignment and mixing speeds to ensure thorough and homogeneous mixing.

- Problem-solving: I have encountered and resolved various issues during plaster mixing, such as uneven mixing, clogging, and consistency problems.

- Maintenance and troubleshooting: I am proficient in maintaining and troubleshooting machine plaster mixers to prevent downtime and ensure smooth operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Plaster Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Plaster Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Machine Operation

Operate and maintain machine plaster mixer to produce plaster and other related materials

- Monitor machine performance and make necessary adjustments to ensure optimal operation

- Troubleshoot and resolve any issues that arise during the mixing process

2. Material Handling

Load and unload raw materials, including cement, sand, and water, into the machine

- Ensure that the materials meet the required specifications

- Maintain a clean and organized work area

3. Quality Control

Monitor the quality of the plaster produced by the machine

- Conduct regular tests to ensure that the plaster meets the desired consistency and strength

- Make adjustments to the mixing process as needed to improve the quality of the plaster

4. Maintenance and Repair

Perform routine maintenance and repairs on the machine plaster mixer

- Lubricate moving parts, clean the machine, and replace worn components

- Work with maintenance personnel to resolve any major issues

Interview Tips

Preparing for an interview for a Machine Plaster Mixer position requires a combination of technical knowledge, industry understanding, and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Job Description

Thoroughly review the company’s website, LinkedIn page, and any available job descriptions. This will provide you with a good understanding of the company’s culture, values, and specific requirements for the role.

2. Highlight Your Technical Expertise

Emphasize your experience operating and maintaining machine plaster mixers. Quantify your accomplishments by providing specific examples of how you have improved efficiency, reduced downtime, or ensured the quality of plaster produced.

3. Showcase Your Quality Control Knowledge

Demonstrate your understanding of quality control procedures and your ability to monitor and maintain the desired specifications for plaster. Highlight your experience in conducting tests, analyzing results, and implementing corrective actions.

4. Prepare for Common Interview Questions

* Tell me about your experience operating a machine plaster mixer. * What are the most important factors to consider when producing high-quality plaster? * How do you handle troubleshooting and resolving issues with the machine? * What is your experience with maintenance and repair tasks? * How do you stay updated on the latest advancements in the industry?5. Practice Your Communication Skills

Practice answering interview questions clearly and concisely. Be prepared to provide specific examples and quantify your accomplishments. Pay attention to your body language and maintain eye contact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Plaster Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!