Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Sander position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

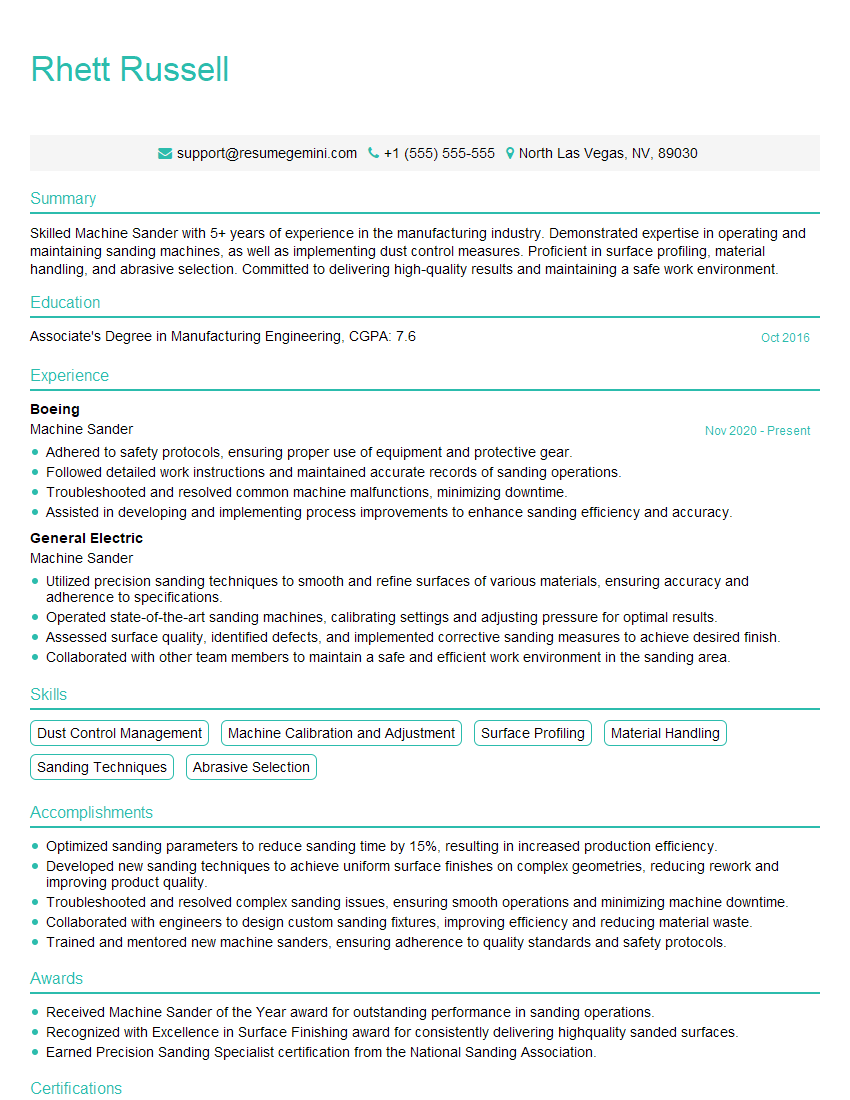

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Sander

1. What are the different types of sanding machines and their uses?

There are various types of sanding machines, each designed for specific applications. Some common types include:

- Belt Sander: A power tool with a continuous abrasive belt that rotates around two or more drums. It is used for general sanding and smoothing surfaces.

- Orbital Sander: A handheld machine with a circular pad that rotates in an orbital motion. It is ideal for fine sanding and finishing.

- Random Orbital Sander: Similar to an orbital sander but with a random orbital motion. It provides a smoother finish and is less likely to leave swirl marks.

- Drum Sander: A machine with a rotating drum covered with abrasive paper. It is suitable for sanding large, flat surfaces.

- Edge Sander: A specialized sander designed for sanding edges and curves. It has a narrow, vertical sanding belt.

2. What safety precautions should be taken when operating a sanding machine?

Preventing Inhalation of Dust

- Wear a dust mask or respirator to protect against inhaling fine particles generated during sanding.

- Use a dust collection system attached to the sander to minimize dust dispersal.

Protecting from Kickback

- Secure the workpiece firmly to prevent kickback caused by the machine catching or binding on the material.

- Hold the sander firmly and maintain control throughout the sanding process.

General Safety Measures

- Inspect the sanding machine regularly and ensure it is in good working condition.

- Read and follow the manufacturer’s instructions carefully.

- Wear appropriate safety gear such as safety glasses, gloves, and earplugs.

- Keep the work area well-ventilated.

3. How do you determine the correct grit of sandpaper for a specific sanding task?

Choosing the right grit of sandpaper depends on the material being sanded and the desired finish. Here are some guidelines:

- Coarse Grit (60-120): For removing large amounts of material or sanding rough surfaces.

- Medium Grit (150-220): For smoothing surfaces and removing minor imperfections.

- Fine Grit (240-400): For finishing and achieving a smooth surface.

- Very Fine Grit (600+): For polishing and achieving a high-gloss finish.

4. What techniques are used to sand different types of materials, such as wood, metal, and plastic?

Sanding different materials requires specific techniques to achieve optimal results:

Wood

- Use fine-grit sandpaper to avoid scratching the wood surface.

- Sand with the grain to prevent tear-out and splintering.

- Use a random orbital sander or hand sanding for smooth, even results.

Metal

- Start with a coarse grit to remove rust or imperfections.

- Gradually move to finer grits to achieve a smooth finish.

- Use a sanding block to ensure even pressure and prevent gouging.

Plastic

- Choose fine-grit sandpaper to avoid melting or damaging the plastic.

- Use a light touch and avoid applying excessive pressure.

- Use a wet sanding technique with water or lubricant to prevent heat buildup.

5. How do you maintain a sanding machine and extend its lifespan?

- Regularly clean and inspect the machine to remove dust and debris.

- Replace the sandpaper or sanding belt when it becomes worn or clogged.

- Lubricate the moving parts as per the manufacturer’s instructions.

- Store the machine in a dry and clean environment when not in use.

- Avoid overloading the machine and using it for extended periods without breaks.

6. What troubleshooting steps would you take if a sanding machine is not operating correctly?

Troubleshooting steps for a malfunctioning sanding machine may include:

- Check the power source: Ensure the machine is plugged in properly and receiving electricity.

- Inspect the sandpaper or sanding belt: Replace it if it is worn, clogged, or torn.

- Examine the motor and brushes: Clean or replace them if necessary.

- Lubricate the moving parts: Apply lubricant to reduce friction and prevent overheating.

- Check the dust collection system: Ensure it is functioning properly and clear of obstructions.

7. How do you ensure the quality of sanded surfaces?

- Use the appropriate grit of sandpaper and sanding technique for the material.

- Inspect the surface regularly during sanding to avoid over-sanding or unevenness.

- Use a sanding block or orbital sander to achieve a consistent and smooth finish.

- Clean the sanded surface thoroughly to remove any dust or debris.

- Apply a protective coating, such as paint or varnish, to protect the sanded surface from damage.

8. What are the common problems encountered during sanding and how do you resolve them?

Some common sanding problems and their solutions include:

- Swirl marks: Use a random orbital sander and fine-grit sandpaper to remove them.

- Gouging or scratching: Use a sanding block or apply lighter pressure when sanding.

- Sandpaper clogging: Choose a higher-quality sandpaper or clean the existing one with compressed air.

- Uneven sanding: Use a sanding block or orbital sander to achieve a consistent finish.

- Dust buildup: Use a dust collection system or vacuum cleaner to remove dust during sanding.

9. How do you stay updated with the latest advancements and techniques in sanding technology?

- Attend industry events and conferences.

- Read trade publications and articles.

- Consult with sanding machine manufacturers and distributors.

- Participate in online forums and discussions.

- Seek training opportunities from experienced professionals.

10. Describe a challenging sanding project you have worked on and how you overcame the difficulties.

In a previous role, I was tasked with sanding a large, antique wooden table that had been damaged and neglected. The surface was uneven, scratched, and stained, requiring a significant amount of work. I approached the project by:

- Assessment: Carefully examining the table to determine the extent of damage and the appropriate sanding techniques.

- Preparation: Removing the old finish and cleaning the surface to create a clean base for sanding.

- Sanding: Using a combination of coarse and fine-grit sandpaper with an orbital sander, I gradually removed the damaged areas and imperfections.

- Refining: Hand sanding with fine-grit sandpaper to achieve a smooth, even surface.

- Finishing: Applying a protective coating to seal and enhance the table’s appearance.

- Evaluation: Regularly inspecting the surface during sanding and after finishing to ensure a high-quality result.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Sanders are responsible for operating and maintaining sanding machines to prepare surfaces for painting, refinishing, or other treatments. Their primary duties include:

1. Machine Operation

Setting up and operating sanding machines, including adjusting speed, feed, and depth of cut

- Selecting and installing appropriate abrasives for different materials and finishes

- Loading and unloading workpieces onto and off of the machine

2. Surface Preparation

Preparing and cleaning surfaces prior to sanding to ensure proper adhesion and finish quality

- Removing old paint, stains, or other contaminants from surfaces

- Leveling or smoothing surfaces to create a uniform finish

3. Quality Control

Inspecting sanded surfaces to ensure they meet desired specifications

- Checking for defects, imperfections, or uneven sanding

- Making adjustments to machine settings or abrasives to improve surface quality

4. Machine Maintenance

Performing regular maintenance on sanding machines to ensure optimal performance and safety

- Lubricating moving parts, changing abrasives, and inspecting for wear and tear

- Troubleshooting and resolving any operational issues

Interview Tips

Preparation is key for a successful interview. Here are some tips to help you ace the interview for a Machine Sander position:

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and industry standing. Also, thoroughly review the job description and identify the key requirements and duties of the Machine Sander position.

- Tailor your responses to demonstrate how your skills and experience align with the specific needs of the company and position.

- Use specific examples from your past experiences to highlight your capabilities and accomplishments.

2. Practice Your Answers

Take time to prepare thoughtful and concise answers to common interview questions. Practice your responses out loud or in front of a mirror to gain confidence and ensure clarity.

- Prepare for questions about your experience operating and maintaining sanding machines.

- Consider questions related to your understanding of surface preparation techniques and quality control measures.

3. Emphasize Relevant Skills and Experience

Highlight your proficiencies in machine operation, surface preparation, quality control, and machine maintenance. Provide specific examples of how you’ve applied these skills in previous roles.

- Quantify your accomplishments whenever possible. For instance, explain how your efforts improved productivity or reduced downtime.

- If you have any certifications or training related to sanding techniques or machine operation, be sure to mention them.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the opportunity. Prepare questions that demonstrate your enthusiasm and curiosity about the position and the company.

- Inquire about the company’s goals and objectives.

- Ask about the specific challenges or opportunities associated with the Machine Sander position.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive for your interview on time. Your appearance and punctuality convey respect and attention to detail.

- Consider wearing clothing that is appropriate for a manufacturing environment, such as comfortable and closed-toed shoes.

- Be sure to arrive a few minutes early to allow for any unexpected delays or unforeseen circumstances.

Next Step:

Now that you’re armed with the knowledge of Machine Sander interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Sander positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini