Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Maintenance Equipment Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Maintenance Equipment Operator so you can tailor your answers to impress potential employers.

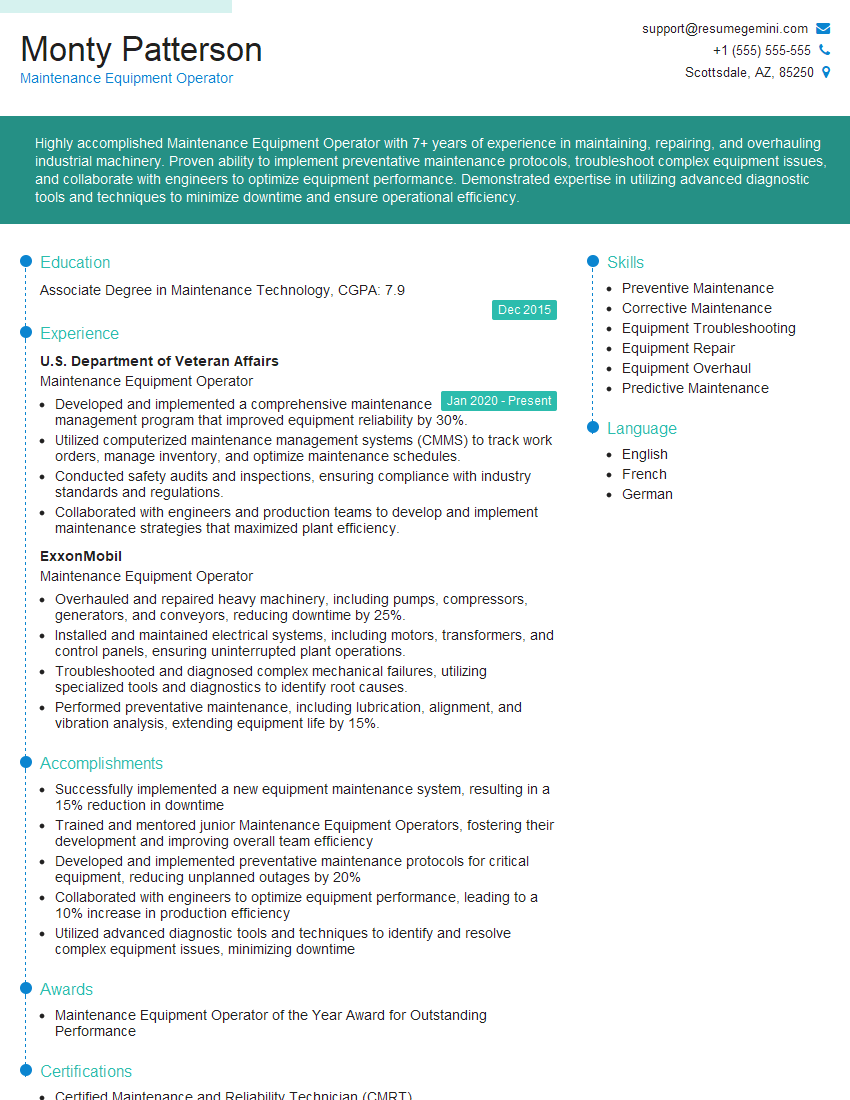

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maintenance Equipment Operator

1. Describe the key responsibilities of a Maintenance Equipment Operator?

As a Maintenance Equipment Operator, I would be responsible for:

- Performing preventive maintenance and repairs on a variety of equipment, including machinery, vehicles, and buildings.

- Operating and troubleshooting equipment to identify and resolve issues.

- Inspecting and diagnosing problems, and making necessary adjustments or repairs.

- Maintaining and updating equipment records and documentation.

- Ensuring that all equipment is operating safely and efficiently.

2. What are the most important skills and qualities for a successful Maintenance Equipment Operator?

- Strong mechanical skills and knowledge of equipment operation and maintenance.

- Excellent troubleshooting and problem-solving abilities.

- Attention to detail and ability to follow instructions precisely.

- Excellent communication and interpersonal skills.

- Physical fitness and ability to work in a variety of conditions.

3. How do you stay up-to-date on the latest equipment and maintenance techniques?

I stay up-to-date on the latest equipment and maintenance techniques by:

- Attending training sessions and workshops.

- Reading industry publications and technical manuals.

- Consulting with manufacturers and other experts.

- Participating in online forums and discussion groups.

4. What is your experience with using computerized maintenance management systems (CMMS)?

I have experience using CMMS in my previous role at [Previous Company]. I was responsible for inputting and tracking maintenance data, generating work orders, and scheduling repairs.

I am familiar with the following CMMS systems:

- Maximo

- SAP

- Oracle

5. What is your approach to safety when working on equipment?

Safety is my top priority when working on equipment. I always follow the manufacturer’s instructions and safety protocols.

- I wear appropriate personal protective equipment (PPE).

- I inspect the equipment before starting any work.

- I ensure that the work area is clean and free of hazards.

- I never operate equipment unless I am authorized to do so.

- I report any safety concerns to my supervisor immediately.

6. How do you handle working in a team environment?

I am a team player and I am comfortable working with others. I am always willing to help out my colleagues and I am always willing to learn from others.

In my previous role, I worked on a team of maintenance technicians. We were responsible for maintaining a fleet of vehicles and equipment. We worked together to identify and resolve issues, and we always made sure that all equipment was operating safely and efficiently.

7. How do you handle working under pressure?

I am able to handle working under pressure. I am able to stay calm and focused, even in stressful situations.

In my previous role, I was often responsible for working on critical equipment. I knew that it was important to get the equipment up and running as quickly as possible, but I never compromised on safety.

I am also able to prioritize my work and make sure that the most important tasks are completed first.

8. What is your experience with working with electrical equipment?

I have experience working with electrical equipment in my previous role at [Previous Company]. I was responsible for maintaining and repairing a variety of electrical equipment, including motors, transformers, and switchgear.

I am also familiar with the National Electrical Code (NEC) and I am always careful to follow all safety precautions when working with electrical equipment.

9. What is your experience with working with hydraulic equipment?

I have experience working with hydraulic equipment in my previous role at [Previous Company]. I was responsible for maintaining and repairing a variety of hydraulic equipment, including pumps, valves, and cylinders.

I am also familiar with the principles of hydraulics and I am always careful to follow all safety precautions when working with hydraulic equipment.

10. What is your experience with working with pneumatic equipment?

I have experience working with pneumatic equipment in my previous role at [Previous Company]. I was responsible for maintaining and repairing a variety of pneumatic equipment, including compressors, valves, and cylinders.

I am also familiar with the principles of pneumatics and I am always careful to follow all safety precautions when working with pneumatic equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maintenance Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maintenance Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Maintenance Equipment Operators play a vital role in ensuring the smooth and efficient operation of various industries. Their primary responsibilities include:

1. Equipment Maintenance and Repair

Inspecting, diagnosing, and repairing a wide range of equipment, including machinery, vehicles, and electrical systems.

- Identifying and resolving equipment malfunctions promptly.

- Performing preventative maintenance to minimize downtime and extend equipment life.

2. Troubleshooting and Problem-Solving

Analyzing equipment issues, diagnosing root causes, and implementing effective solutions.

- Using diagnostic tools and techniques to identify problems.

- Working with other technicians and engineers to resolve complex issues.

3. Equipment Monitoring and Inspection

Monitoring equipment performance, identifying potential problems, and taking corrective actions.

- Conducting regular inspections and testing.

- Maintaining detailed maintenance records and logs.

4. Safety and Regulatory Compliance

Ensuring compliance with safety regulations and industry standards.

- Following established safety protocols.

- Using personal protective equipment (PPE) appropriately.

Interview Tips

Preparing for an interview for a Maintenance Equipment Operator position requires thorough research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain an in-depth understanding of the company’s business, industry trends, and specific job requirements.

- Visit the company’s website and social media pages.

- Read industry publications and attend industry events.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize your technical skills, problem-solving abilities, and safety consciousness.

- Quantify your accomplishments using specific examples.

- Use action verbs to describe your responsibilities and contributions.

3. Practice Common Interview Questions

Prepare for common interview questions related to your experience, technical skills, and troubleshooting abilities.

- Anticipate questions about your experience with specific equipment or maintenance procedures.

- Rehearse how you would respond to questions about safety and problem-solving.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for the interview.

- Choose attire that is appropriate for the industry and position.

- Plan your route and allow ample time for traffic or unexpected delays.

5. Be Enthusiastic and Confident

Convey your enthusiasm for the position and the industry.

- Show your passion for maintenance and equipment operation.

- Maintain eye contact, speak clearly, and express yourself confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Maintenance Equipment Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.