Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Maintenance Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

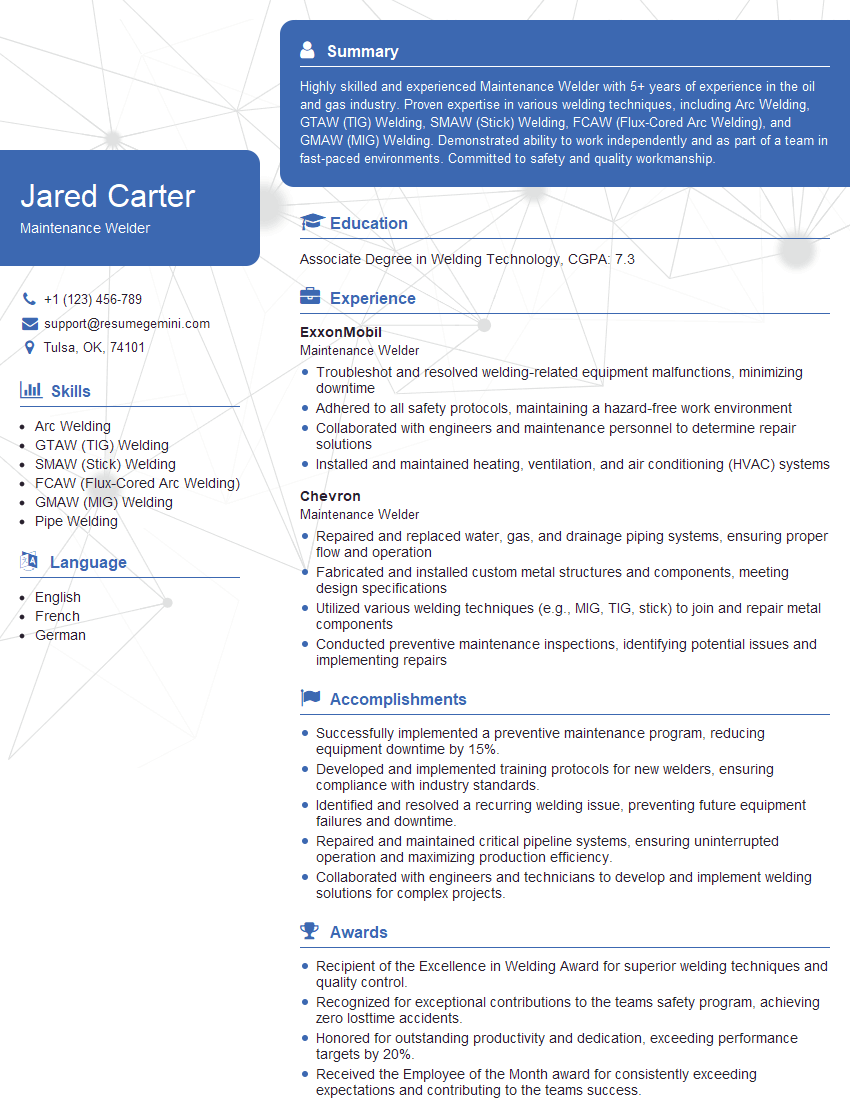

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Maintenance Welder

1. Can you describe the various welding processes you are proficient in?

I am highly proficient in a diverse range of welding processes, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW) also known as MIG Welding

- Flux-Cored Arc Welding (FCAW)

- Tungsten Inert Gas Welding (TIG)

- Plasma Arc Welding (PAW)

2. How do you ensure the quality of your welds?

Inspection and Verification

- Conduct thorough visual inspections to identify any apparent defects.

- Utilize non-destructive testing methods such as radiographic testing or ultrasonic testing to ensure weld integrity.

Compliance with Standards

- Adhere to industry standards and specifications, such as ASME, AWS, and API, to maintain quality.

- Follow welding procedures and specifications to ensure consistent results.

3. Can you explain the importance of proper joint preparation for welding?

Proper joint preparation is crucial for successful welding as it:

- Ensures proper penetration and fusion of the weld metal.

- Minimizes the risk of defects such as porosity, slag inclusions, and undercut.

- Improves the mechanical strength and integrity of the weld joint.

4. Describe the steps involved in troubleshooting a welding machine.

Troubleshooting a welding machine involves a systematic approach:

- Identify the problem accurately by observing symptoms and gathering information.

- Inspect the power source, cables, and connections for any loose connections or damage.

- Check the welding torch and consumables, such as the tip and nozzle, for wear or blockages.

- Review the welding parameters and adjust them if necessary based on the material and joint configuration.

- Consult the manufacturer’s manual or seek assistance from a qualified technician if the issue persists.

5. What are the potential safety hazards associated with welding and how do you mitigate them?

Welding involves several potential hazards, and I take the following precautions to mitigate them:

- Fumes and Gases: Use proper ventilation and wear a respirator to prevent inhalation of harmful fumes.

- Arc Radiation: Wear appropriate protective clothing and welding helmet to shield from intense ultraviolet and infrared radiation.

- Electrical Hazards: Ensure proper grounding and insulation to prevent electrical shocks.

- Fire and Explosions: Keep the work area clean and free of flammable materials, and have fire extinguishers readily available.

- Eye Injuries: Always wear safety glasses or a welding helmet to protect eyes from sparks and molten metal.

6. How do you stay up-to-date with the latest welding techniques and technologies?

To stay current with advancements in welding, I engage in continuous learning through:

- Attending industry conferences, workshops, and training programs.

- Reading technical journals, articles, and online resources.

- Networking with other welders and professionals in the field.

- Seeking certifications and qualifications to demonstrate my proficiency.

7. Can you describe a challenging welding project you have worked on and how you overcame the difficulties?

Project Description

I was tasked with welding a complex piping system with tight tolerances and limited accessibility.

Challenges

- Confined workspaces and awkward joint positions

- Precise alignment and fitting requirements

- Ensuring high-quality welds in challenging conditions

Solutions

- Utilized specialized welding techniques and tools to access difficult areas.

- Developed innovative fixtures and supports to maintain proper alignment.

- Conducted thorough pre-weld planning and preparation to minimize errors.

- Collaborated with engineers and inspectors to ensure compliance with specifications.

8. How do you prioritize tasks and manage your time effectively in a fast-paced maintenance environment?

In a fast-paced maintenance environment, I prioritize tasks and manage my time effectively by:

- Assessing Urgency and Importance: Evaluating work orders to determine the criticality and impact of each task.

- Planning and Scheduling: Creating a schedule that optimizes the use of my time and resources.

- Delegating and Collaborating: Assigning tasks to other team members or collaborating with specialists when necessary.

- Utilizing Technology: Leveraging tools such as work order management systems and maintenance software to streamline processes.

- Continuous Improvement: Regularly reviewing my workflow and seeking opportunities to enhance efficiency.

9. How do you ensure that your welding work meets the required quality standards?

I ensure the quality of my welding work by adhering to the following practices:

- Compliance with Standards: Following industry standards and specifications, such as AWS, ASME, and API.

- Rigorous Inspection: Conducting thorough visual inspections and utilizing non-destructive testing methods to verify weld integrity.

- Documentation and Certification: Maintaining detailed records of welding procedures and qualifications.

- Continuous Improvement: Seeking feedback and actively working to enhance my skills and knowledge.

- Collaboration with Quality Assurance: Cooperating with quality assurance personnel to ensure adherence to quality standards.

10. Describe your experience in working with blueprints and technical drawings.

I am proficient in interpreting blueprints and technical drawings and have extensive experience in using them to guide my welding work:

- Decoding Symbols and Specifications: Accurately interpreting welding symbols, dimensions, and tolerances.

- Visualizing Complex Structures: Understanding the spatial relationships and assembly sequences depicted in drawings.

- Identifying Material Requirements: Determining the appropriate welding materials and techniques based on the specified materials.

- Collaborating with Engineers: Effectively communicating with engineers to clarify design intent and ensure accurate implementation.

- Maintaining Quality Control: Using drawings as a reference for weld quality and adherence to specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Maintenance Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Maintenance Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Maintenance Welder is responsible for maintaining, repairing, and fabricating metal structures, equipment, and components. The key job responsibilities include:

1. Welding and Fabrication

Weld and fabricate metal components, parts, and structures using a variety of welding processes, including arc welding, MIG welding, and TIG welding.

- Analyze and interpret welding specifications and drawings.

- Select and set up welding equipment and materials.

2. Maintenance and Repair

Perform maintenance and repair on metal structures, equipment, and components, including inspection, troubleshooting, and replacement of worn or damaged parts.

- Inspect equipment and structures for defects.

- Repair or replace damaged or worn parts.

3. Safety and Quality Assurance

Follow safety protocols and procedures while performing welding and fabrication tasks.

- Ensure the quality of welding work meets industry standards.

- Maintain a clean and organized work area.

4. Other Responsibilities

Perform other tasks as assigned, such as assisting with installation of equipment or training new employees.

- Communicate with other maintenance personnel and departments.

- Maintain accurate records of welding and repair activities.

Interview Tips

To prepare for an interview for a Maintenance Welder position, consider the following tips.

1. Research the Company and Industry

Familiarize yourself with the company you are applying to and the industry they operate in.

- Visit the company website and LinkedIn page.

- Research industry trends and publications.

2. Practice Your Welding Skills

Demonstrate your welding skills by practicing before the interview.

- If possible, set up a welding station at home or in a community workshop.

- Practice welding different types of joints and materials.

3. Prepare for Technical Questions

Expect questions about your welding techniques, knowledge of welding processes, and experience with welding equipment.

- Review welding specifications and codes.

- Familiarize yourself with different welding equipment and their applications.

4. Showcase Your Safety Awareness

Emphasize your commitment to safety by highlighting your knowledge of safety regulations and your experience in following safety protocols.

- Explain how you ensure the safety of yourself and others in the workplace.

- Discuss your experience with using personal protective equipment and following lockout/tagout procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Maintenance Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.