Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Manual Machinist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Manual Machinist so you can tailor your answers to impress potential employers.

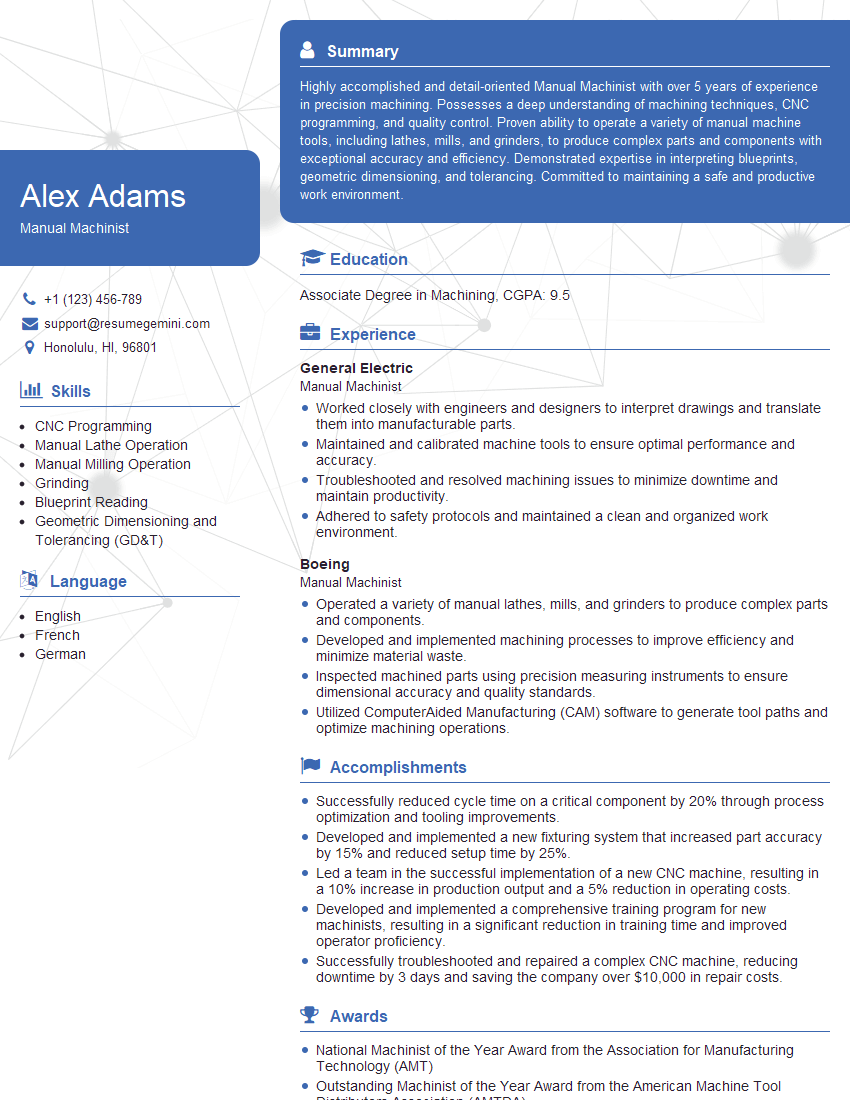

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manual Machinist

1. What are the different types of manual machining operations?

Manual machining involves various operations, including:

- Turning: Shaping cylindrical workpieces using a lathe.

- Milling: Removing material from a workpiece using rotating cutters.

- Drilling: Creating circular holes in workpieces using a drill bit.

- Grinding: Finishing or shaping workpieces using abrasive wheels.

- Sawing: Cutting workpieces using a saw.

2. Describe the process of setting up a manual lathe.

Mounting the workpiece

- Select and secure the appropriate chuck or collet.

- Center the workpiece in the chuck or collet.

- Tighten the chuck or collet to hold the workpiece securely.

Setting the cutting tool

- Select the appropriate cutting tool for the operation.

- Install the cutting tool in the tool post.

- Adjust the height and angle of the cutting tool.

Adjusting the speed and feed

- Determine the optimal cutting speed and feed rate for the material and operation.

- Set the lathe’s spindle speed and feed rate accordingly.

3. Explain the difference between HSS and carbide cutting tools.

- HSS (High-Speed Steel):

- Less expensive than carbide tools.

- Suitable for a wide range of materials.

- Lower wear resistance than carbide tools.

- Carbide:

- More expensive than HSS tools.

- Higher wear resistance, allowing for faster cutting speeds.

- Less versatile than HSS tools, may not be suitable for all materials.

4. What are the safety precautions to be followed while operating a manual mill?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Securely clamp the workpiece to the mill table.

- Ensure that the mill is properly grounded.

- Keep hands and loose clothing away from moving parts.

- Never leave the mill running unattended.

5. Describe the process of drilling a hole using a manual drill press.

- Select the appropriate drill bit for the size and material of the hole.

- Securely clamp the workpiece to the drill press table.

- Set the drill press speed and feed rate.

- Align the drill bit with the desired hole location.

- Start drilling and maintain a steady pressure on the drill bit.

6. Explain the importance of coolant in manual machining operations.

- Lubricates the cutting tool, reducing friction and wear.

- Cools the workpiece and cutting tool, preventing overheating and tool damage.

- Flushes away chips and swarf, improving surface finish and tool life.

7. Describe the different types of measuring tools used in manual machining.

- Calipers: Measure the outside and inside dimensions of workpieces.

- Micrometers: Measure precise dimensions with high accuracy.

- Dial indicators: Measure small displacements and surface irregularities.

- Gauges: Verify specific dimensions or shapes, such as hole gauges or thread gauges.

8. What are the common errors that can occur during manual machining?

- Tool chatter: Vibrations that can affect the surface finish and accuracy.

- Overheating: Excessive heat can damage the workpiece or cutting tool.

- Poor tool selection: Using the wrong tool for the job can result in poor performance.

- Incorrect setup: Improper mounting of the workpiece or cutting tool can lead to errors.

- Human error: Mistakes can occur due to inattention, fatigue, or lack of skill.

9. Describe your experience in troubleshooting manual machining problems.

Provide specific examples of problems you have encountered and the steps you took to resolve them. Highlight your analytical, problem-solving, and troubleshooting skills.

10. How do you stay updated on the latest advancements in manual machining?

- Attend industry workshops and conferences.

- Read trade publications and technical articles.

- Network with other machinists and professionals in the field.

- Explore online resources and forums.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manual Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manual Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manual Machinists are responsible for operating and maintaining a variety of manual machinery to produce precision parts for various industries. They use their skills and knowledge to create complex components that meet exact specifications.

1. Operating Machinery

Manual Machinists are proficient in operating a wide range of manual machines, including lathes, milling machines, grinders, and drill presses. They are able to set up and operate these machines to produce precise parts according to blueprints and specifications.

- Set up and operate manual machines, such as lathes, milling machines, grinders, and drill presses

- Interpret blueprints and technical drawings to determine machining requirements

- Select and use appropriate cutting tools and materials

- Monitor the machining process and make adjustments as needed

2. Measuring and Inspecting Parts

Manual Machinists are responsible for measuring and inspecting parts to ensure that they meet specifications. They use a variety of measuring tools, including calipers, micrometers, and gauges, to ensure that parts are within tolerance.

- Measure and inspect parts to ensure that they meet specifications

- Use a variety of measuring tools, such as calipers, micrometers, and gauges

- Identify and correct any errors in parts

- Maintain a clean and organized work area

3. Maintaining Machinery

Manual Machinists are also responsible for maintaining the machinery they use. They perform regular maintenance tasks, such as cleaning, lubrication, and repairs, to ensure that the machinery is operating properly.

- Perform regular maintenance tasks on machinery

- Clean, lubricate, and repair machinery as needed

- Troubleshoot and resolve mechanical problems

- Maintain a safe and efficient work environment

4. Working with Other Team Members

Manual Machinists often work with other team members, including engineers, designers, and other machinists. They are able to communicate effectively and work cooperatively to complete projects on time and within budget.

- Work with other team members to complete projects

- Communicate effectively with engineers, designers, and other machinists

- Contribute to a positive and productive work environment

- Follow safety procedures and regulations

Interview Tips

Preparing for an interview can help you make a great impression on the interviewer and increase your chances of getting the job. Here are a few tips to help you prepare for your Manual Machinist interview:

1. Research the Company

Before your interview, take some time to research the company. This will help you understand the company’s culture, values, and products or services. You can also learn about the company’s history, mission, and goals. This information will help you answer questions about the company during your interview.

- Visit the company’s website

- Read news articles and press releases about the company

- Check out the company’s social media pages

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked during your Manual Machinist interview. It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with manual machining?

- What are your salary expectations?

3. Bring a Portfolio of Your Work

If you have a portfolio of your work, be sure to bring it to your interview. This will give the interviewer a chance to see your skills and abilities firsthand. Your portfolio should include examples of your best work, such as precision parts that you have machined.

- Include examples of your work that demonstrate your skills and abilities

- Organize your portfolio in a professional manner

- Be prepared to discuss your work with the interviewer

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean and pressed clothes that are appropriate for a business setting. You should also avoid wearing excessive jewelry or perfume.

- Wear clean and pressed clothes

- Dress in a business casual style

- Avoid wearing excessive jewelry or perfume

5. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early. This will give you time to relax and prepare before your interview begins.

- Arrive for your interview on time

- If you are running late, call or email the interviewer to let them know

Next Step:

Now that you’re armed with the knowledge of Manual Machinist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Manual Machinist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini