Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Meat Dresser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

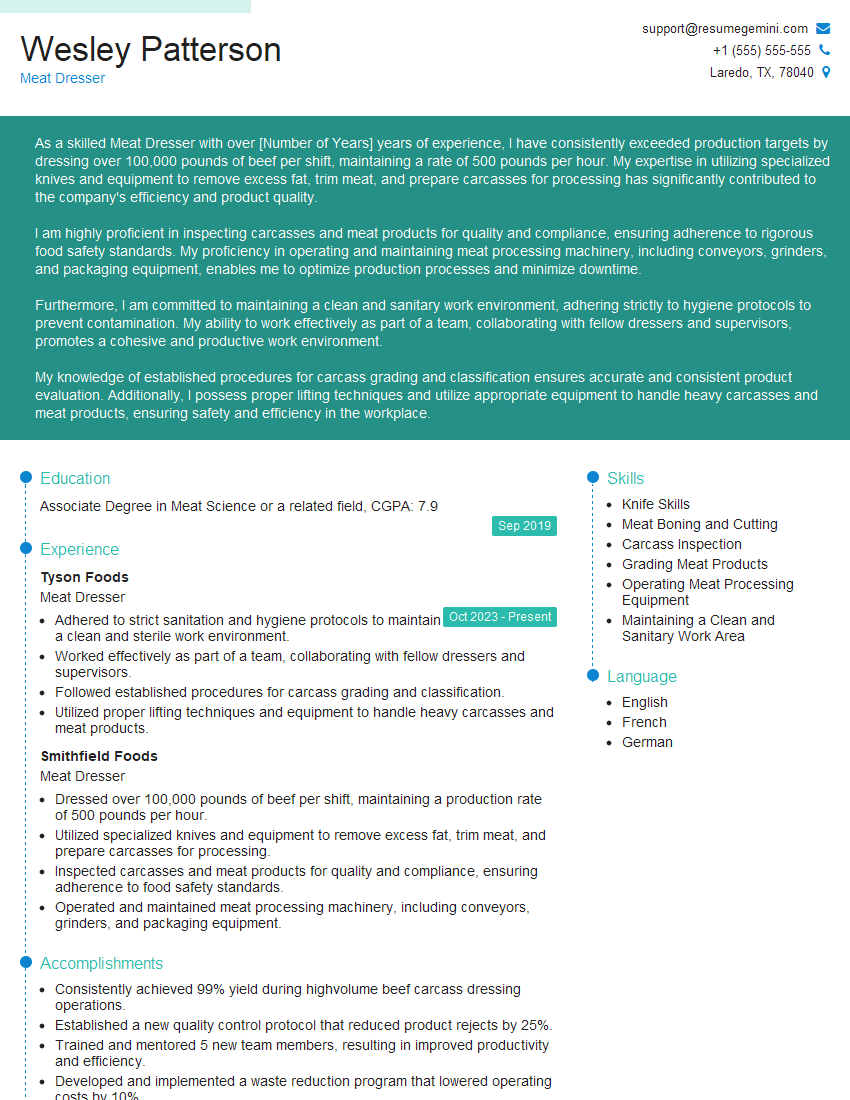

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Meat Dresser

1. Explain the process of deboning a beef carcass?

- First, the head and viscera are removed. Next, the carcass is split down the midline into two sides.

- Each side is then further divided into primal cuts, which are the major muscle groups of the animal.

- The deboning process involves removing the bones from the primal cuts. Depending on the desired end product, the deboning can be done either manually or mechanically.

- Once the bones have been removed, the meat is trimmed and further processed as needed.

2. What are the different grades of beef and how are they determined?

- The United States Department of Agriculture (USDA) grades beef according to its quality. The grades are Prime, Choice, Select, and Standard.

- The grade is determined by several factors, including the amount of marbling in the meat, the maturity of the animal, and the overall appearance of the carcass.

- Prime is the highest grade of beef and is characterized by its exceptional marbling and tenderness.

- Choice and Select are the most common grades of beef found in supermarkets and restaurants.

- Standard is the lowest grade of beef and is typically used for ground beef and other processed meats.

3. What are the most common cuts of beef and how are they best cooked?

- The most common cuts of beef include the ribeye, strip loin, filet mignon, and ground beef.

- Ribeye is a flavorful and juicy cut that is best cooked grilled or roasted.

- Strip loin is a leaner cut that is best cooked grilled or pan-fried.

- Filet mignon is a tender and flavorful cut that is best cooked grilled or pan-seared.

- Ground beef is a versatile cut that can be used in a variety of dishes, such as hamburgers, tacos, and spaghetti sauce.

4. What are the different types of meat inspection and what are their purposes?

- Ante-mortem inspection is performed on live animals before they are slaughtered. The purpose of ante-mortem inspection is to identify any animals that are sick or injured and to prevent them from entering the food supply.

- Post-mortem inspection is performed on slaughtered animals after they have been killed. The purpose of post-mortem inspection is to identify any carcasses that are diseased or otherwise unfit for human consumption.

- Process inspection is performed on meat products during processing to ensure that they are safe and wholesome.

5. What are the most common hazards associated with meat processing and how can they be controlled?

- The most common hazards associated with meat processing include bacterial contamination, chemical contamination, and physical hazards.

- Bacterial contamination can be controlled by using proper sanitation practices, such as washing hands and equipment, and by controlling the temperature of the meat.

- Chemical contamination can be controlled by using safe and approved chemicals, and by following proper storage and handling procedures.

- Physical hazards can be controlled by using proper equipment and by following safe work practices.

6. What are the different types of meat processing equipment and what are their uses?

- The different types of meat processing equipment include grinders, mixers, and slicers.

- Grinders are used to grind meat into smaller pieces.

- Mixers are used to combine different ingredients together to create meat products, such as sausage and ground beef.

- Slicers are used to slice meat into thin slices.

7. What are the different types of meat packaging and what are their advantages and disadvantages?

- The different types of meat packaging include vacuum packaging, modified atmosphere packaging, and shrink wrapping.

- Vacuum packaging removes the air from the package, which helps to extend the shelf life of the meat.

- Modified atmosphere packaging uses a mixture of gases to create an atmosphere inside the package that is not conducive to bacterial growth, which also helps to extend the shelf life of the meat.

- Shrink wrapping uses a plastic film to tightly wrap the meat, which helps to protect it from moisture loss and contamination.

8. What are the different types of meat products and how are they made?

- The different types of meat products include fresh meat, cured meat, and processed meat.

- Fresh meat is meat that has not been subjected to any processing other than chilling or freezing.

- Cured meat is meat that has been treated with salt or other curing agents to preserve it.

- Processed meat is meat that has been subjected to a process that changes its texture or flavor, such as smoking, canning, or drying.

9. What are the different types of meat by-products and how are they used?

- The different types of meat by-products include bones, hides, and offal.

- Bones are used to make bone meal, which is a fertilizer, and to make gelatin, which is used in a variety of food products.

- Hides are used to make leather.

- Offal is used to make pet food and other animal feed products.

10. What are the different types of meat industry regulations and what are their purposes?

- The different types of meat industry regulations include those that govern the production, processing, and distribution of meat.

- The purpose of these regulations is to ensure that meat is safe, wholesome, and properly labeled.

- The Food Safety and Inspection Service (FSIS) of the USDA is responsible for enforcing these regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Meat Dresser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Meat Dresser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Meat Dressers are responsible for the daily operations of a meat processing plant. They are responsible for slaughtering, dressing, and cutting meat, as well as ensuring that all meat products meet quality and safety standards.

1. Slaughter and Dress Animals

Meat Dressers begin their day by slaughtering animals. They use a variety of tools to humanely kill the animals, including knives, stun guns, and bolt guns. Once the animals are dead, they are dressed by removing their skin, head, and internal organs.

- Use knives, stun guns, and bolt guns to humanely kill animals

- Remove the skin, head, and internal organs of animals

2. Cut and Package Meat

Meat Dressers cut and package meat according to customer specifications. They use a variety of knives and saws to cut meat into different shapes and sizes. They also package meat in a variety of ways, including vacuum sealing, shrink wrapping, and boxing.

- Use knives and saws to cut meat into different shapes and sizes

- Package meat in a variety of ways, including vacuum sealing, shrink wrapping, and boxing

3. Maintain a Clean and Safe Work Environment

Meat Dressers are responsible for maintaining a clean and safe work environment. They clean and disinfect work surfaces and equipment on a regular basis. They also follow all safety protocols, including wearing protective clothing and using sharp knives safely.

- Clean and disinfect work surfaces and equipment

- Follow all safety protocols, including wearing protective clothing and using sharp knives safely

4. Other Duties

In addition to their primary responsibilities, Meat Dressers may also be responsible for other duties, such as:

- Loading and unloading meat products

- Operating and maintaining meat processing equipment

- Keeping records of meat production

- Assisting with other tasks as needed

Interview Tips

To prepare for an interview for a Meat Dresser position, you should:

1. Research the Company

Before you go for your interview, take some time to research the company. This will help you better understand the company’s culture, values, and goals. You can do this by visiting the company’s website, reading articles about the company, and talking to people who work there.

- Visit the company’s website

- Read articles about the company

- Talk to people who work there

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked when interviewing for a Meat Dresser position. These questions include:

- Tell me about your experience in the meat industry.

- What are your strengths as a Meat Dresser?

- What are your weaknesses as a Meat Dresser?

- Why do you want to work for this company?

- What are your salary expectations?

Take some time to practice answering these questions so that you can give confident and concise answers during your interview.

3. Be Prepared to Work in a Fast-Paced Environment

Meat processing plants are fast-paced environments. You will need to be able to work quickly and efficiently to keep up with the demand. Be prepared to work long hours and weekends, and to be on your feet for most of the day.

- Work quickly and efficiently to keep up with the demand

- Be prepared to work long hours and weekends

- Be on your feet for most of the day

4. Be Aware of the Physical Demands of the Job

Meat Dressers perform physically demanding work. You will need to be able to lift heavy weights, stand for long periods of time, and work in cold and wet conditions. Be sure to be in good physical condition before applying for this job.

- Lift heavy weights

- Stand for long periods of time

- Work in cold and wet conditions

5. Be a Team Player

Meat Dressers work as part of a team. You will need to be able to work well with others and be willing to help out your team members. You should be able to take direction from your supervisor and follow instructions.

- Work well with others

- Be willing to help out your team members

- Take direction from your supervisor and follow instructions

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Meat Dresser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!