Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mechanical Ordnance Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

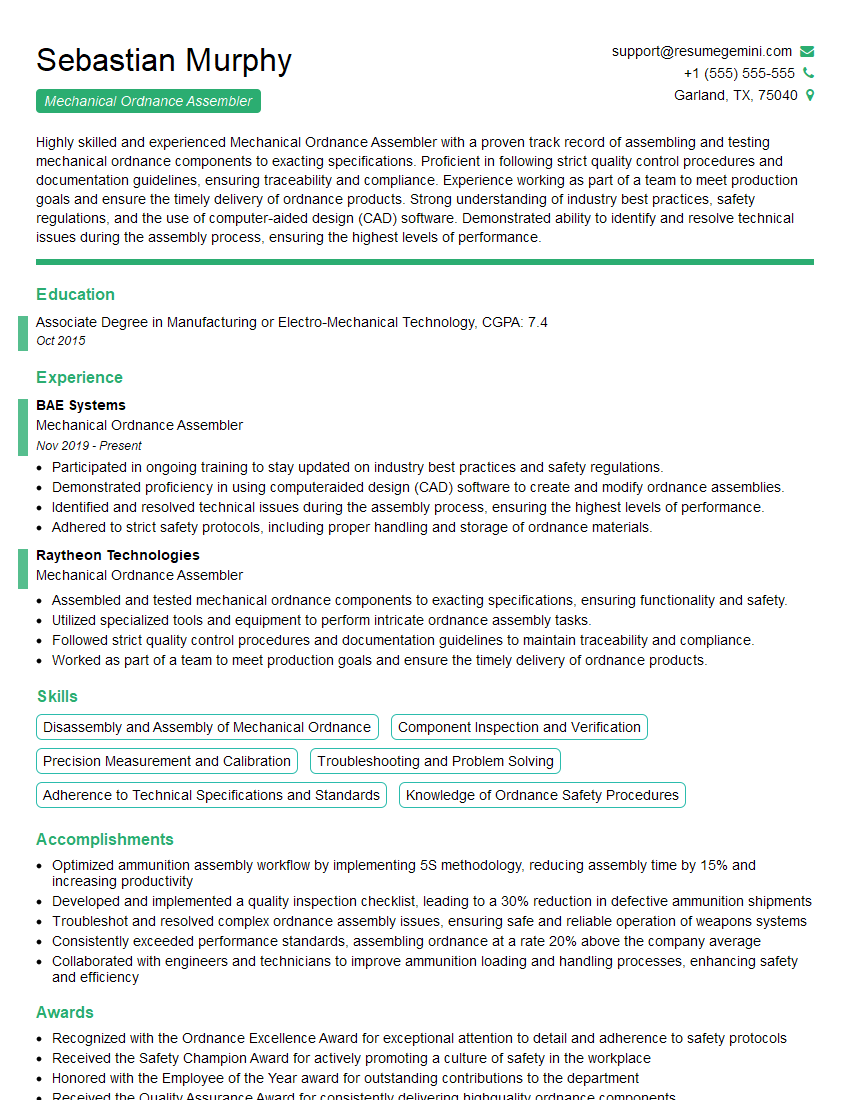

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Ordnance Assembler

1. Explain the process of assembling a mechanical ordnance component?

The process of assembling a mechanical ordnance component involves several steps:

- Receiving and inspecting the component parts

- Preparing the parts for assembly, including cleaning and lubricating

- Assembling the parts according to the technical drawings and specifications

- Testing and inspecting the assembled component to ensure it meets the required standards

- Packaging and shipping the component

2. What are the different types of mechanical ordnance components you have experience assembling?

Experience with various components

- Artillery shells

- Rockets

- Mortar rounds

- Guided missiles

- Bombs

Experience with specific components

- Fuzes

- Warheads

- Propellants

- Guidance systems

- Control surfaces

3. What are the safety precautions you take when assembling mechanical ordnance components?

When assembling mechanical ordnance components, it is crucial to follow strict safety precautions to prevent accidents and injuries:

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection

- Work in a designated and controlled environment

- Follow established procedures and protocols

- Inspect components carefully before handling

- Use proper tools and equipment

- Be aware of the potential hazards associated with the components

- Never attempt to disassemble or modify components

- Report any safety concerns or incidents immediately

4. What are the quality control procedures you follow when assembling mechanical ordnance components?

To ensure the quality and reliability of the assembled components, I adhere to stringent quality control procedures:

- Inspecting components upon receipt and before assembly

- Following technical drawings and specifications precisely

- Using calibrated measuring equipment

- Performing functional tests and inspections

- Documenting all assembly and inspection processes

- Maintaining a clean and organized work area

- Receiving ongoing training and certification

5. How do you stay up-to-date on the latest techniques and technologies in mechanical ordnance assembly?

To stay abreast of advancements in the field, I employ various strategies:

- Attending industry conferences, workshops, and training programs

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Consulting with experts and colleagues

- Seeking feedback from supervisors and quality control personnel

6. What are the challenges you have faced in assembling mechanical ordnance components and how did you overcome them?

Challenge 1

Assembling a complex guidance system with tight tolerances

Solution

- Used precision measuring tools and followed detailed technical drawings

- Consulted with engineers and quality control personnel

- Conducted multiple tests and inspections to ensure accuracy

Challenge 2

Working with hazardous materials in a high-pressure environment

Solution

- Followed established safety protocols and wore appropriate PPE

- Maintained a clean and organized work area

- Communicated effectively with colleagues to ensure coordination

7. Describe a time when you had to work independently to assemble a critical mechanical ordnance component

Situation

Assembling a fuze for a guided missile

Actions

- Carefully reviewed technical drawings and specifications

- Inspected all components and ensured they met the required standards

- Assembled the component following the established procedures

- Conducted thorough testing and inspection to verify proper functionality

- Documented all assembly and inspection processes

Outcome

Successfully assembled the critical component, which met all specifications and passed all quality control tests

8. What motivates you to work as a Mechanical Ordnance Assembler?

- Passion for working with complex mechanical systems

- Desire to contribute to national security and defense

- Appreciation for the precision and attention to detail required

- Commitment to safety and quality

- Opportunity for continuous learning and advancement

9. How do you handle the stress and pressure of assembling critical mechanical ordnance components?

- Stay calm and focused under pressure

- Follow established procedures and protocols

- Communicate effectively with colleagues and supervisors

- Take breaks when needed to clear my mind and refocus

- Maintain a positive and proactive attitude

10. Why are you interested in working for our company?

I am highly interested in working for your company because:

- Your company is a leader in the ordnance industry with a strong reputation

- I am impressed by your commitment to safety, quality, and innovation

- I believe my skills and experience would be a valuable asset to your team

- I am eager to contribute to your company’s success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Ordnance Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Ordnance Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mechanical Ordnance Assembler is responsible for assembling, installing, maintaining, and repairing mechanical and electrical ordnance systems and components, ensuring their proper functioning.

1. Assembly and Installation

Assembles and installs ordnance systems and components, including weapons, ammunition, and guidance systems.

- Reads and interprets technical drawings, schematics, and specifications.

- Uses specialized tools, equipment, and measuring devices to assemble and install components.

2. Maintenance and Repair

Conducts scheduled and unscheduled maintenance on ordnance systems and components.

- Inspects and tests systems for defects or malfunctions.

- Disassembles and reassembles components to replace or repair damaged parts.

3. Troubleshooting and Calibration

Troubleshoots and resolves malfunctions in ordnance systems.

- Uses diagnostic equipment and techniques to identify the cause of malfunctions.

- Calibrates systems to ensure accuracy and performance.

4. Quality Assurance and Control

Maintains quality standards and follows safety protocols.

- Inspects assembled and installed systems to verify compliance with specifications.

- Follows safety regulations and hazardous materials handling procedures.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some key tips to help you ace your interview for a Mechanical Ordnance Assembler position.

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific role you’re interviewing for. This will help you understand the company’s culture, values, and specific requirements for the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay updated on the latest developments in the field.

2. Practice Your Answers

Anticipate common interview questions and practice your answers ahead of time. This will help you feel more confident and articulate during the interview.

- Prepare a brief introduction that highlights your relevant skills and experience.

- Rehearse answering questions about your technical expertise, troubleshooting abilities, and safety protocols.

3. Highlight Your Hands-on Experience

Mechanical Ordnance Assemblers require strong hands-on skills. Emphasize your practical experience in assembling, maintaining, and repairing ordnance systems.

- Provide specific examples of projects you’ve worked on and the techniques you’ve used.

- Quantify your accomplishments whenever possible, using metrics such as the number of systems assembled or repaired.

4. Demonstrate Your Safety Awareness

Safety is paramount in this role. Showcase your understanding of safety protocols and your commitment to following them.

- Describe your experience with hazardous materials handling and safety regulations.

- Explain how you ensure the safe operation and maintenance of ordnance systems.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanical Ordnance Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!