Feeling lost in a sea of interview questions? Landed that dream interview for Metal Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

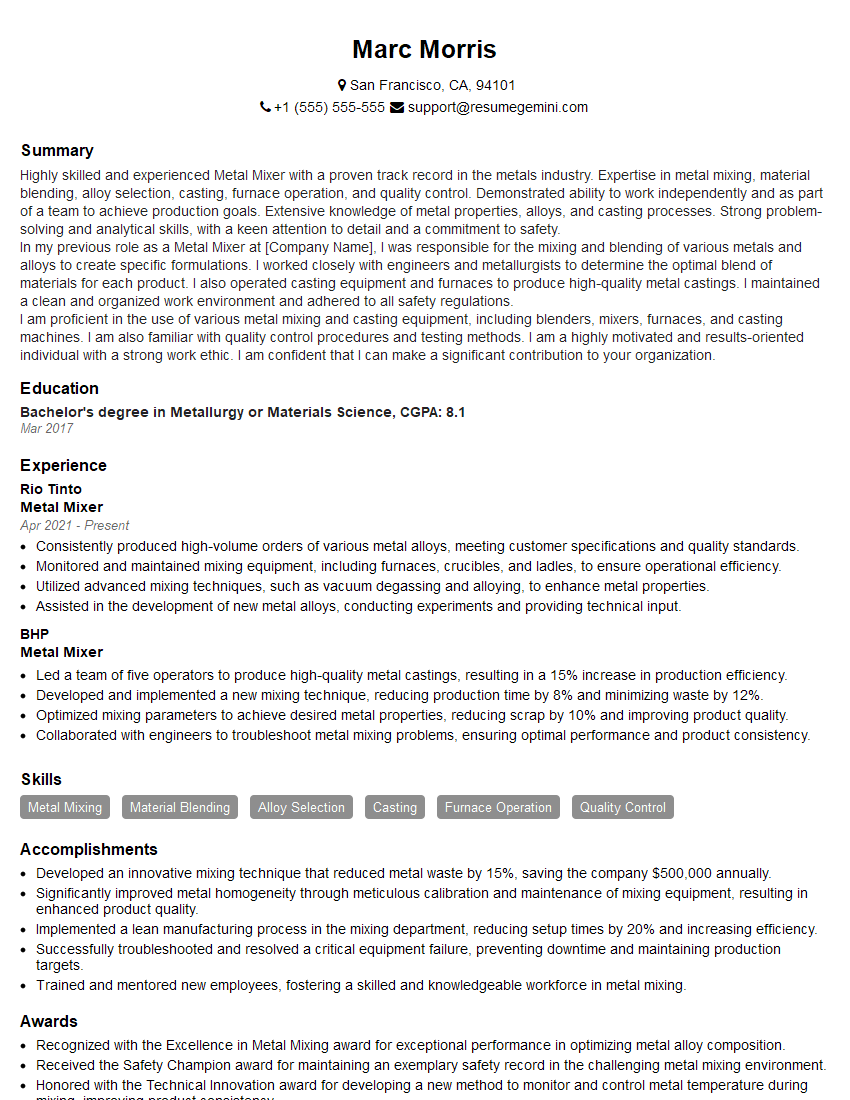

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Mixer

1. Explain the process of mixing different metals to create alloys?

- Melting the metals to be mixed at their respective melting points

- Homogenizing the molten metals by stirring or agitation to ensure even distribution of the components

- Controlling the cooling rate and temperature to obtain the desired microstructure and properties

- Solidifying the alloy by cooling, which can be done in various ways (e.g., casting, rolling, extrusion)

2. What factors should be considered when selecting the appropriate mixing technique for a particular alloy composition?

Melt temperature and viscosity

- The higher the temperature, the lower the viscosity, making it easier to mix the metals.

Metal reactivity

- Mixing metals with high reactivity can require specialized techniques to prevent undesirable reactions.

Desired alloy properties

- The mixing technique can influence the resulting grain structure and mechanical properties of the alloy.

3. Describe the role of post-mixing processes, such as heat treatment, in the production of metal alloys?

- Improving mechanical properties (e.g., strength, hardness, ductility) by modifying the microstructure

- Relieving internal stresses introduced during mixing or forming

- Enhancing corrosion resistance or other specific properties

4. How do you ensure the quality and consistency of the mixed alloys?

- Establishing and adhering to standardized mixing procedures

- Regularly calibrating and maintaining mixing equipment

- Conducting quality control tests on the mixed alloys (e.g., chemical analysis, mechanical testing) to verify compliance with specifications

- Implementing a quality management system to monitor and continuously improve processes

5. Explain the importance of understanding the phase diagram of a metal alloy system?

- Predicting the phases present and their relative proportions at different temperatures and compositions

- Determining the solidification behavior and identifying potential issues like segregation or precipitation

- Guiding the design of heat treatment processes to achieve desired properties

6. How do you address challenges related to mixing and processing of reactive metals, such as titanium and aluminum?

- Using specialized equipment and inert atmospheres to prevent oxidation and contamination

- Optimizing mixing parameters to balance reactivity control and alloy homogeneity

- Employing post-mixing treatments to remove impurities and enhance alloy properties

7. Describe your experience in working with different types of mixing equipment, such as induction furnaces, planetary mixers, and vacuum mixers?

- Induction furnaces: High-temperature melting and mixing under controlled atmosphere

- Planetary mixers: Thorough mixing of viscous or powdered materials

- Vacuum mixers: Mixing under vacuum to remove gases and impurities

8. How do you stay updated on the latest advancements and best practices in metal mixing technology?

- Attending industry conferences and workshops

- Reading research papers and technical journals

- Consulting with experts and vendors

9. Can you provide an example of a successful mixing project you have worked on?

10. How do you ensure safety and environmental compliance during metal mixing operations?

- Following established safety protocols and wearing appropriate protective gear

- Properly handling and storing hazardous materials

- Maintaining a clean and organized work area

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Mixers are responsible for operating and maintaining equipment that mixes molten metal to create alloys. They also ensure that the metal is of the correct composition and temperature for casting or other processes.

1. Operate and maintain mixing equipment

Metal Mixers operate and maintain a variety of equipment, including furnaces, mixers, and casting machines. They must be able to troubleshoot and repair problems with this equipment.

- Operate furnaces to melt and mix metals.

- Control the temperature and composition of the molten metal.

- Pour the molten metal into molds or casting machines.

2. Ensure the quality of the metal

Metal Mixers must ensure that the metal they produce is of the correct composition and temperature for casting or other processes. They must be able to test the metal and make adjustments as needed.

- Test the molten metal to ensure that it meets the required specifications.

- Make adjustments to the metal’s composition or temperature as needed.

- Maintain records of the metal’s composition and temperature.

3. Safety

Metal Mixers must follow all safety procedures and wear the appropriate personal protective equipment (PPE). They must be aware of the hazards of working with molten metal and be able to take steps to prevent accidents.

- Follow all safety procedures and wear the appropriate PPE.

- Be aware of the hazards of working with molten metal.

- Take steps to prevent accidents.

4. Other duties

Metal Mixers may also perform other duties, such as cleaning and maintaining the work area, and assisting other workers.

- Clean and maintain the work area.

- Assist other workers.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go on an interview, it’s important to research the company and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and make note of the key requirements.

- Talk to people who work at the company or have worked there in the past.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Think about your skills and experience and how they relate to the job requirements.

- Prepare a brief and engaging answer to the question “Tell me about yourself.”

- Be prepared to discuss your interest in the position and why you’re the right person for the job.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the job and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location on time, or even a few minutes early.

4. Be confident and enthusiastic

Confidence and enthusiasm are two important qualities that interviewers look for in candidates. Be confident in your abilities and show the interviewer that you’re excited about the opportunity to work for their company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic about the position and the company.

5. Ask questions

Asking questions at the end of an interview shows the interviewer that you’re interested in the position and that you’re taking the interview seriously.

- Prepare a few questions to ask the interviewer about the job, the company, or the industry.

- Ask questions that are specific and relevant to the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!