Feeling lost in a sea of interview questions? Landed that dream interview for Mill Beam Fitter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mill Beam Fitter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

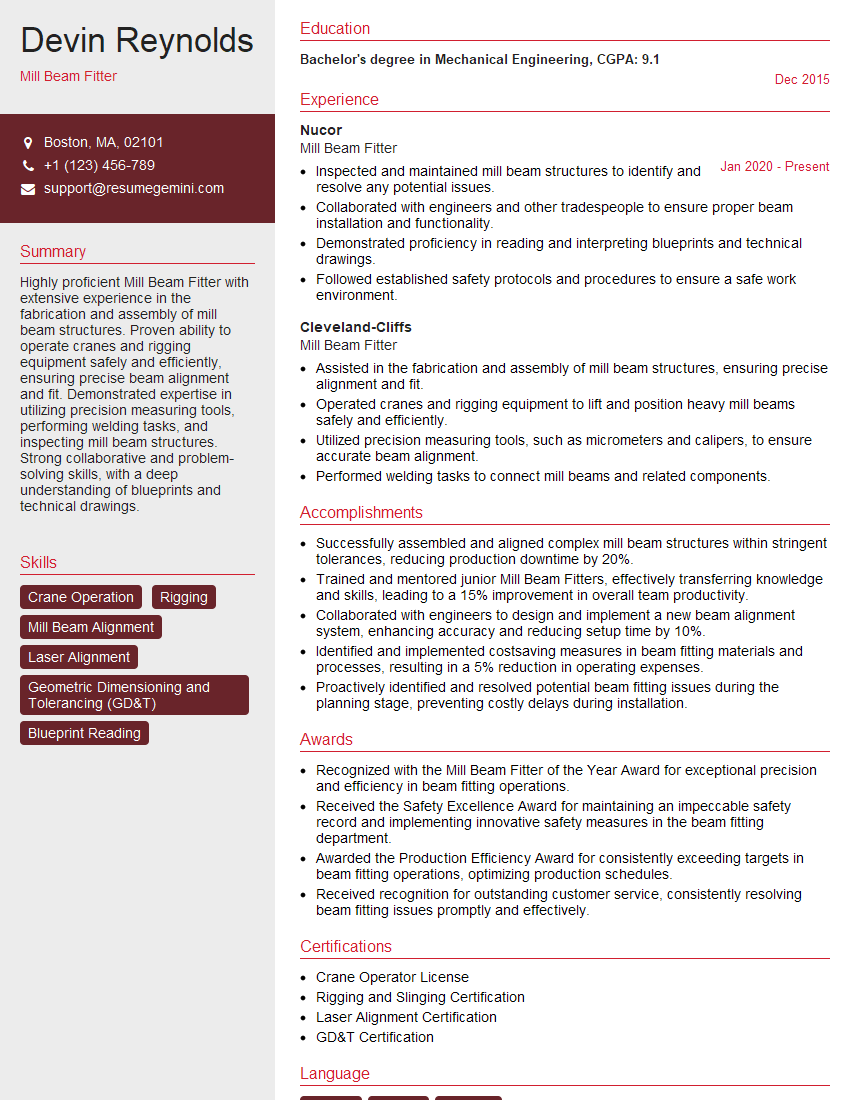

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Beam Fitter

1. What are the key responsibilities of a Mill Beam Fitter?

As a Mill Beam Fitter, my primary responsibilities would include:

- Accurately and precision-fit mill beams, columns, and supporting structures.

- Install, align, and level components using specialized tools and techniques.

2. Describe your experience in using surveying and alignment equipment.

Surveying Equipment

- Proficient in using laser levels, transit levels, and total stations.

- Experience in establishing benchmarks, site lines, and transferring measurements precisely.

Alignment Equipment

- Skilled in operating optical alignment tools, such as theodolites and laser trackers.

- Expertise in aligning shafts, couplings, and other critical components.

3. How do you approach the installation of a new mill beam?

My approach to installing a new mill beam involves:

- Thoroughly reviewing blueprints and specifications.

- Establishing precise reference points using surveying equipment.

- Preparing the beam and supporting structures for installation.

- Safely lifting and positioning the beam using cranes or other lifting devices.

- Securing and aligning the beam to exact tolerances.

4. What techniques do you use to ensure that beams are installed level and plumb?

I employ the following techniques to ensure that beams are installed level and plumb:

- Precisely measure and level the base of the beam’s support structure using laser levels.

- Use shims and leveling bolts to adjust the beam’s position.

- Constantly monitor the beam’s alignment using plumb bobs, laser trackers, or string lines.

5. Describe your experience with fabricating and welding support structures.

I am proficient in fabricating and welding support structures, including:

- Reading and interpreting fabrication drawings.

- Cutting, bending, and assembling steel components.

- Performing welding operations using various welding techniques (e.g., GMAW, SMAW).

- Verifying the structural integrity and alignment of the fabricated structures.

6. How do you maintain and calibrate your precision measuring tools?

Regularly maintain and calibrate my precision measuring tools to ensure their accuracy and reliability:

- Follow manufacturer’s calibration procedures using certified calibration equipment.

- Perform daily zero checks and routine inspections.

- Record calibration results for traceability and quality control purposes.

7. What safety precautions do you take when working with heavy machinery and materials?

I prioritize safety when working with heavy machinery and materials by:

- Wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, and earplugs.

- Inspect equipment for potential hazards and ensure it is in good working order.

- Follow established safety protocols and operate machinery according to manufacturer’s guidelines.

- Maintain a clean and organized work area to minimize risks.

8. How do you stay updated on the latest industry standards and best practices for mill beam fitting?

I stay abreast of industry standards and best practices by:

- Attending industry conferences and seminars.

- Reading technical journals and publications.

- Consulting with experienced professionals and manufacturers.

- Participating in continuing education programs.

9. Describe a situation where you had to troubleshoot and resolve a complex issue with a mill beam installation.

In a previous project, I encountered a complex issue where a mill beam was not aligning properly. I methodically:

- Verified the accuracy of my surveying equipment and calibration.

- Inspected the beam and support structures for any defects or damage.

- Re-measured and re-established reference points to ensure precision.

- Identified a slight misalignment in the support structure and made adjustments using shims and leveling bolts.

- Successfully installed the beam within the required tolerances, resolving the alignment issue.

10. How do you prioritize and manage multiple tasks in a fast-paced work environment?

In fast-paced environments, I prioritize and manage tasks effectively by:

- Creating a clear list of tasks and assigning priorities based on urgency and importance.

- Breaking down large tasks into smaller, manageable steps.

- Delegating responsibilities to team members when appropriate.

- Utilizing project management tools to track progress and identify potential bottlenecks.

11. What is your experience with working in confined spaces?

I have experience working in confined spaces, including:

- Assessing and mitigating potential hazards, such as limited ventilation and obstructed access.

- Using specialized equipment and tools designed for working in confined spaces.

- Maintaining constant communication with colleagues and following established safety protocols.

12. Describe how you would handle a situation where you are working on a team and have a disagreement with a colleague.

When working in a team and encountering a disagreement with a colleague, I would approach the situation professionally by:

- Respectfully expressing my perspective and providing supporting evidence.

- Actively listening to the other person’s point of view and seeking common ground.

- Exploring alternative solutions and finding a compromise that benefits the team.

- Prioritizing the project’s success and maintaining a positive and collaborative environment.

13. What is your availability to work overtime or on weekends?

My availability to work overtime or on weekends is flexible. I understand that project deadlines and unexpected events may require additional hours, and I am committed to supporting the team’s needs:

- I am available to work overtime as needed, with reasonable notice.

- For weekend work, I am usually available with prior arrangement and notice.

- I prioritize completing tasks on time and to a high standard, even if it requires additional hours.

14. Are there any questions that you have for us regarding the role or the company?

Yes, I do have a few questions:

- What is the company’s track record in terms of safety and quality standards?

- Can you provide more details about the opportunities for professional development and advancement within the organization?

- What is the company’s environmental sustainability policy?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Beam Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Beam Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Beam Fitters play a crucial role in maintaining and repairing milling equipment in various industries, including manufacturing, mining, and construction.

1. Installation and Maintenance of Mill Beams

Mill Beam Fitters are responsible for installing, aligning, and maintaining mill beams, which are structural components that support grinding equipment in mills.

- Read and interpret blueprints and specifications to determine beam placement and alignment.

- Position and secure mill beams using precision measuring tools and techniques.

- Inspect beams regularly for wear, damage, or misalignment, and perform necessary repairs or adjustments.

2. Equipment Modification and Repair

Mill Beam Fitters also handle equipment modifications and repairs to ensure optimal performance of the milling process.

- Modify and adjust mill beams to accommodate changes in equipment or process requirements.

- Troubleshoot and repair mill beams, including welding, grinding, and machining.

- Replace worn or damaged beam components to maintain structural integrity and equipment efficiency.

3. Safety and Compliance

Ensuring safety and compliance with industry regulations is a primary responsibility of Mill Beam Fitters.

- Adhere to safety protocols and wear appropriate protective gear during installation, maintenance, and repairs.

- Follow established procedures and guidelines to ensure proper equipment operation and minimize risks.

- Stay updated on industry best practices and regulatory requirements related to mill beam fitting.

4. Teamwork and Communication

Mill Beam Fitters often work as part of a team, collaborating with other maintenance personnel and engineers.

- Communicate effectively with team members to coordinate tasks, share information, and resolve issues.

- Provide clear and concise reports on beam inspections, repairs, and modifications.

- Seek assistance and guidance from supervisors and engineers when necessary.

Interview Tips

To ace a Mill Beam Fitter interview, it’s essential to prepare thoroughly and showcase your skills and experience aligned with the key job responsibilities.

1. Research and Knowledge

Demonstrate your understanding of the industry, mill beam fitting techniques, and safety regulations.

- Read industry publications and online resources to stay updated on best practices.

- Review relevant certification programs offered by professional organizations.

- Familiarize yourself with the company’s specific equipment and processes.

2. Highlight Experience and Skills

Emphasize your practical experience in mill beam installation, maintenance, and repair.

- Quantify your accomplishments using specific metrics and examples.

- Describe your problem-solving abilities and how you handled challenging situations.

- Showcase your proficiency in using precision measuring tools, welding equipment, and other relevant tools.

3. Teamwork and Communication

Highlight your ability to work effectively in a team environment and communicate clearly.

- Provide examples of successful team projects where you collaborated effectively.

- Explain how you communicate complex technical information to non-technical personnel.

4. Safety and Compliance

Demonstrate your commitment to safety and compliance with industry regulations.

- Discuss your adherence to safety protocols and your understanding of risk assessment procedures.

- Explain your experience with relevant safety certifications or compliance programs.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mill Beam Fitter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.