Are you gearing up for an interview for a Miller Apprentice position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Miller Apprentice and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

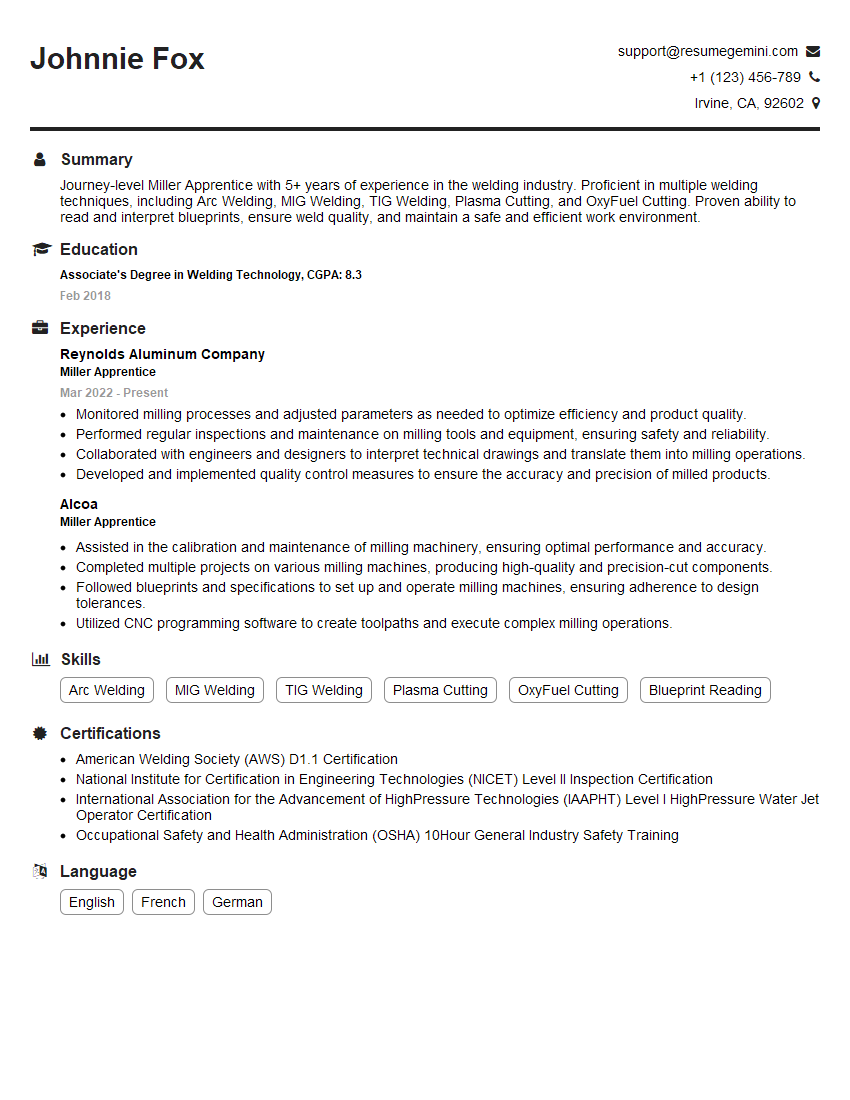

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Miller Apprentice

1. How do you ensure the accuracy and precision of your grinding operations?

- Regularly calibrating and maintaining grinding machines to meet specified tolerances.

- Using precision measuring instruments such as micrometers, calipers, and gauges to verify dimensions.

- Adhering to established grinding parameters and following quality control procedures.

- Inspecting finished workpieces thoroughly to ensure they meet specifications.

- Implementing statistical process control techniques to monitor and improve grinding processes.

2. How do you troubleshoot common grinding problems, such as chatter, burrs, and surface finish issues?

Identifying the root cause of the problem:

- Analyzing machine settings, workpiece material, grinding wheel selection, and coolant conditions.

- Inspecting the grinding wheel for wear, damage, or improper dressing.

- Verifying the rigidity of the workpiece setup and machine components.

Applying corrective actions:

- Adjusting machine parameters such as speed, feed, and depth of cut.

- Selecting an appropriate grinding wheel with the correct grit, bond, and dressing method.

- Optimizing coolant flow and concentration to reduce heat and improve lubrication.

- Re-dressing or replacing the grinding wheel as necessary.

- Tightening loose components or reinforcing the workpiece setup.

3. How do you calculate the grinding wheel speed and feed rate for a specific grinding operation?

- Determining the desired surface finish, material removal rate, and workpiece material.

- Referring to grinding wheel manufacturer’s specifications for recommended speed ranges.

- Calculating the grinding wheel speed based on its diameter and the desired surface feet per minute (SFPM).

- Adjusting the feed rate based on the workpiece material, grinding wheel grit, and desired stock removal.

- Performing test runs and fine-tuning the speed and feed rate to optimize grinding performance.

4. What safety precautions do you take when operating grinding machines?

- Wearing appropriate personal protective equipment (PPE), including eye protection, gloves, and hearing protection.

- Ensuring the machine is properly grounded and shielded to prevent electrical hazards.

- Inspecting the grinding wheel for cracks or damage before mounting it on the machine.

- Following proper wheel mounting procedures and using the correct flanges and guards.

- Maintaining a clean and organized work area to prevent tripping hazards.

- Being aware of the machine’s operating limits and avoiding overloading it.

5. How do you maintain and care for grinding wheels?

- Regularly cleaning the grinding wheel with a brush or compressed air to remove swarf and debris.

- Dressing the grinding wheel to maintain its shape and cutting efficiency.

- Storing grinding wheels properly in a dry, controlled environment to prevent moisture absorption.

- Inspecting grinding wheels for signs of wear or damage before each use.

- Following manufacturer’s recommendations for wheel storage, handling, and disposal.

6. What types of abrasives are used in grinding wheels, and how do their properties affect the grinding process?

- Aluminum oxide: Hard and durable, suitable for grinding ferrous metals and producing a fine finish.

- Silicon carbide: Sharper and more friable than aluminum oxide, ideal for grinding non-ferrous metals and achieving a coarse finish.

- Ceramic: High hardness and wear resistance, used for precision grinding and high-speed applications.

- Cubic boron nitride (CBN): Extremely hard and durable, used for grinding hardened steels and superalloys.

- Diamond: The hardest abrasive, used for grinding very hard materials such as ceramics and composites.

7. How do you select the appropriate grinding wheel for a specific grinding operation?

- Considering the material to be ground and the desired surface finish.

- Matching the abrasive type and grit size to the workpiece material and grinding application.

- Selecting the appropriate wheel bond and structure based on the grinding conditions.

- Referring to grinding wheel manufacturer’s recommendations for specific applications.

- Conducting test runs to optimize grinding performance and verify wheel selection.

8. What are the different types of grinding machines, and what are their advantages and disadvantages?

- Advantages: High production rates, precise roundness and surface finish, no center holes required.

- Disadvantages: Limited to cylindrical workpieces, requires specialized equipment.

- Advantages: Precision grinding of cylindrical surfaces, high accuracy and surface finish.

- Disadvantages: Slower than centerless grinding, requires centering and fixturing.

- Advantages: Flat and parallel surfaces, high precision, suitable for large workpieces.

- Disadvantages: Slower than cylindrical grinding, requires careful setup.

- Advantages: Grinds internal surfaces, such as bores and holes, precision and surface finish.

- Disadvantages: Complex setup, limited access to internal surfaces.

Centerless grinding:

Cylindrical grinding:

Surface grinding:

Internal grinding:

9. How do you ensure quality and consistency in your grinding operations?

- Following established grinding procedures and specifications.

- Regularly calibrating and maintaining grinding machines.

- Using precision measuring instruments to verify workpiece dimensions.

- Inspecting finished workpieces thoroughly for defects and non-conformities.

- Implementing statistical process control techniques to monitor and improve grinding processes.

10. What are your strengths and weaknesses as a Miller Apprentice?

- Proficient in various grinding techniques, including centerless, cylindrical, surface, and internal grinding.

- Strong knowledge of grinding wheel selection and maintenance.

- Excellent attention to detail and commitment to quality.

- Ability to work independently and as part of a team.

- Limited experience with advanced grinding techniques, such as creep feed grinding.

- Working on complex, high-tolerance workpieces.

- I am actively seeking opportunities to expand my skills and knowledge in these areas.

Strengths:

Weaknesses:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Miller Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Miller Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Miller Apprentices assist experienced millers in the production of flour, animal feed, and other mill products. They perform a variety of tasks, including operating and maintaining milling machinery, conducting quality control checks, and assisting with shipping and receiving operations.

1. Miller Apprentice Responsibilities

- Operate and maintain milling machinery

- Conduct quality control checks

- Assist with shipping and receiving operations

- Clean and maintain work area

- Perform other duties as assigned

Interview Tips

Preparing for an interview for a Miller Apprentice position involves researching the company and the position, practicing your answers to common interview questions, and dressing professionally. Here are some additional tips that may help you ace your interview:

1. Research the Company and the Position

It is important to take the time to learn about the company you are interviewing with, and the specific position you are applying for. This will help you to understand the company’s culture, values, and goals, and to tailor your answers to the interviewer’s questions accordingly.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

- Review the job description carefully

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write out your answers to some of the most common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Avoid wearing casual clothing, such as jeans or t-shirts

- If you are unsure about what to wear, err on the side of caution and dress more formally

- Make sure your clothes are clean and free of wrinkles

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and positive about their work. Show the interviewer that you are excited about the opportunity to work for their company, and that you are confident in your abilities.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be passionate about your work experience and skills

5. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Prepare a few questions to ask the interviewer at the end of the interview

- These questions should be specific to the position and the company

- Avoid asking questions that are already answered in the job description or on the company’s website

6. Follow Up

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position, and that you appreciate their time.

- Send a thank-you note to the interviewer

- In your thank-you note, reiterate your interest in the position and thank the interviewer for their time

- If you have any additional questions, you can include them in your thank-you note

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Miller Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.