Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mixer Lever Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

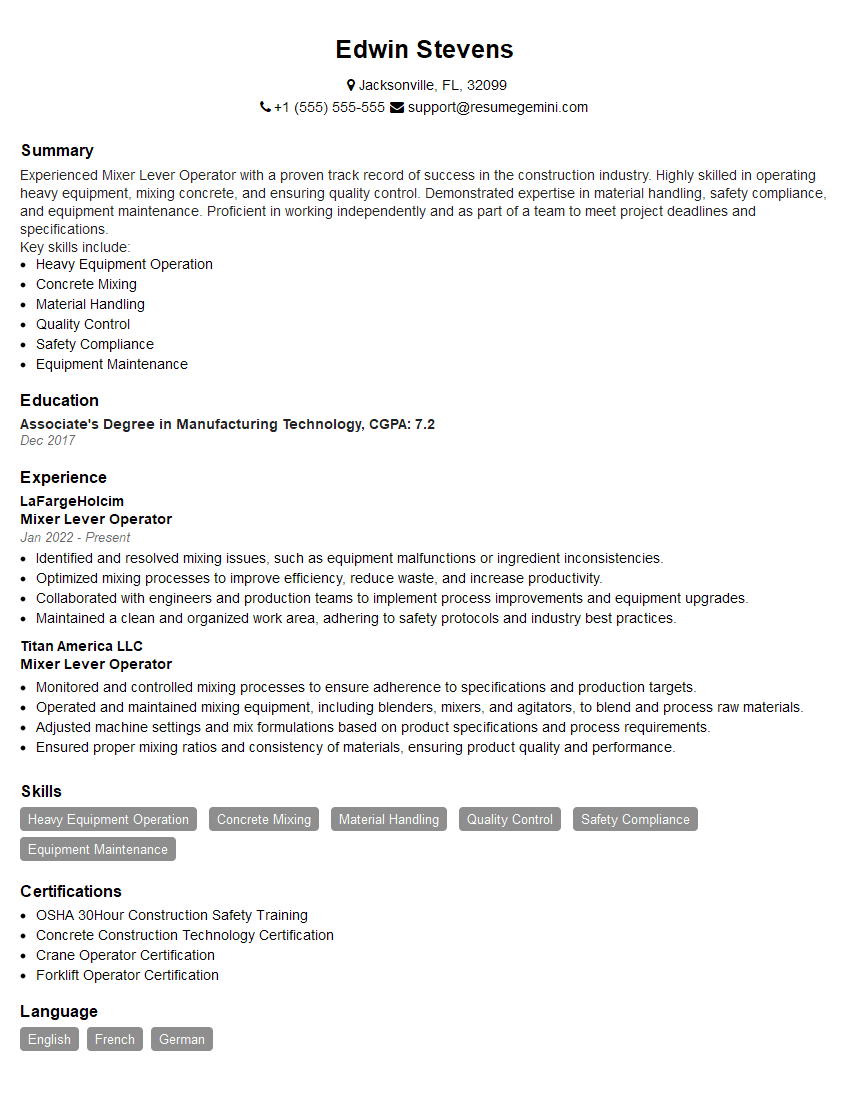

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixer Lever Operator

1. Explain the process of mixing different materials in the mixer?

- First, I would ensure that I have a clear understanding of the recipe and the desired proportions of each ingredient.

- Next, I would inspect the equipment and make sure it is clean and in good working order.

- I would then measure and add the ingredients to the mixer in the correct order and sequence.

- Once all the ingredients are added, I would start the mixing process and monitor the mixture closely.

- I would make adjustments to the mixing speed and time as needed to ensure that the mixture is properly blended.

- Finally, I would discharge the mixture from the mixer and clean the equipment thoroughly.

2. What are the different types of mixers and their applications?

Batch Mixers

- Used for small batches of material

- Ingredients are added to the mixer all at once

- Mixing is done for a set period of time

Continuous Mixers

- Used for large batches of material

- Ingredients are added to the mixer continuously

- Mixing is done as the material moves through the mixer

Pug Mill Mixers

- Used for mixing viscous materials

- Consists of a rotating shaft with blades that knead and mix the material

3. What are the safety precautions that should be taken when operating a mixer?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Never operate a mixer that is not properly guarded.

- Never reach into a mixer while it is running.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for the safe operation of the mixer.

4. What are the common problems that can occur with mixers and how can they be resolved?

- Problem: The mixer is not mixing properly.

- Possible causes: The blades are worn or damaged, the mixer is not properly calibrated, or the ingredients are not being added in the correct order.

- Solutions: Inspect the blades and replace them if necessary, calibrate the mixer according to the manufacturer’s instructions, and ensure that the ingredients are being added in the correct order.

- Problem: The mixer is overheating.

- Possible causes: The motor is overloaded, the mixer is not properly ventilated, or the bearings are worn.

- Solutions: Reduce the load on the motor, ensure that the mixer is properly ventilated, and replace the bearings if necessary.

5. What are the maintenance procedures that should be performed on a mixer?

- Regularly inspect the mixer for any signs of wear or damage.

- Lubricate the mixer according to the manufacturer’s instructions.

- Clean the mixer thoroughly after each use.

- Have the mixer inspected by a qualified technician on a regular basis.

6. What is the difference between a dry mix and a wet mix?

- Dry mix: A dry mix is a mixture of dry ingredients, such as cement, sand, and gravel.

- Wet mix: A wet mix is a mixture of dry ingredients and water.

7. What are the advantages and disadvantages of using a mixer?

Advantages

- Mixers can be used to mix a wide variety of materials.

- Mixers can be used to achieve a consistent mix.

- Mixers can be used to increase the efficiency of the mixing process.

Disadvantages

- Mixers can be expensive to purchase and maintain.

- Mixers can be noisy and dusty.

- Mixers can be dangerous to operate.

8. How do you ensure the quality of the mixed product?

- Follow the recipe and mixing instructions carefully.

- Use high-quality ingredients.

- Monitor the mixing process closely and make adjustments as needed.

- Test the mixed product to ensure that it meets the desired specifications.

- Keep records of the mixing process and the test results.

9. What is your experience with troubleshooting mixer problems?

I have experience troubleshooting a variety of mixer problems, including:

- Mixer not mixing properly

- Mixer overheating

- Mixer leaking

- Mixer making noise

I am able to quickly identify the cause of the problem and take the necessary steps to resolve it.

10. What are your career goals?

My career goal is to become a production manager in a manufacturing environment. I am confident that my skills and experience would make me a valuable asset to any organization.

I am eager to learn new things and take on new challenges. I am also a team player and I am always willing to go the extra mile.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixer Lever Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixer Lever Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mixer Lever Operators perform these key job responsibilities:

1. Operate Machinery

Mixer Lever Operators use a variety of equipment and machinery in order to perform their duties. This includes machines such as:

- Concrete mixers

- Forklifts

- Wheel loaders

- Bulldozers

2. Monitor Production

Mixer Lever Operators are also responsible for monitoring the production process. This involves keeping an eye on the quality of the concrete being produced. They make sure that the concrete meets the required specifications. They also make sure that the production process is running smoothly and efficiently.

3. Maintain Equipment

Mixer Lever Operators are also responsible for maintaining the equipment they use. This involves keeping the equipment clean and in good working condition. They also perform minor repairs and adjustments as needed.

4. Follow Safety Procedures

Mixer Lever Operators are required to follow all safety procedures. This is to ensure their own safety as well as the safety of those around them. They wear protective gear and follow all safety guidelines.

Interview Tips

Here are some interview tips to help you ace your Mixer Lever Operator interview:

1. Research the Company

Before your interview, take some time to research the company. This will help you learn more about the company’s culture and values. It will also help you understand the company’s business model and goals. This knowledge will help you answer questions about the company in a more informed way.

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident during your interview. It will also help you stay on track and avoid rambling.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and pressed.

4. Be Yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you. So don’t try to be someone you’re not. Just be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mixer Lever Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!