Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mixing Roll Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

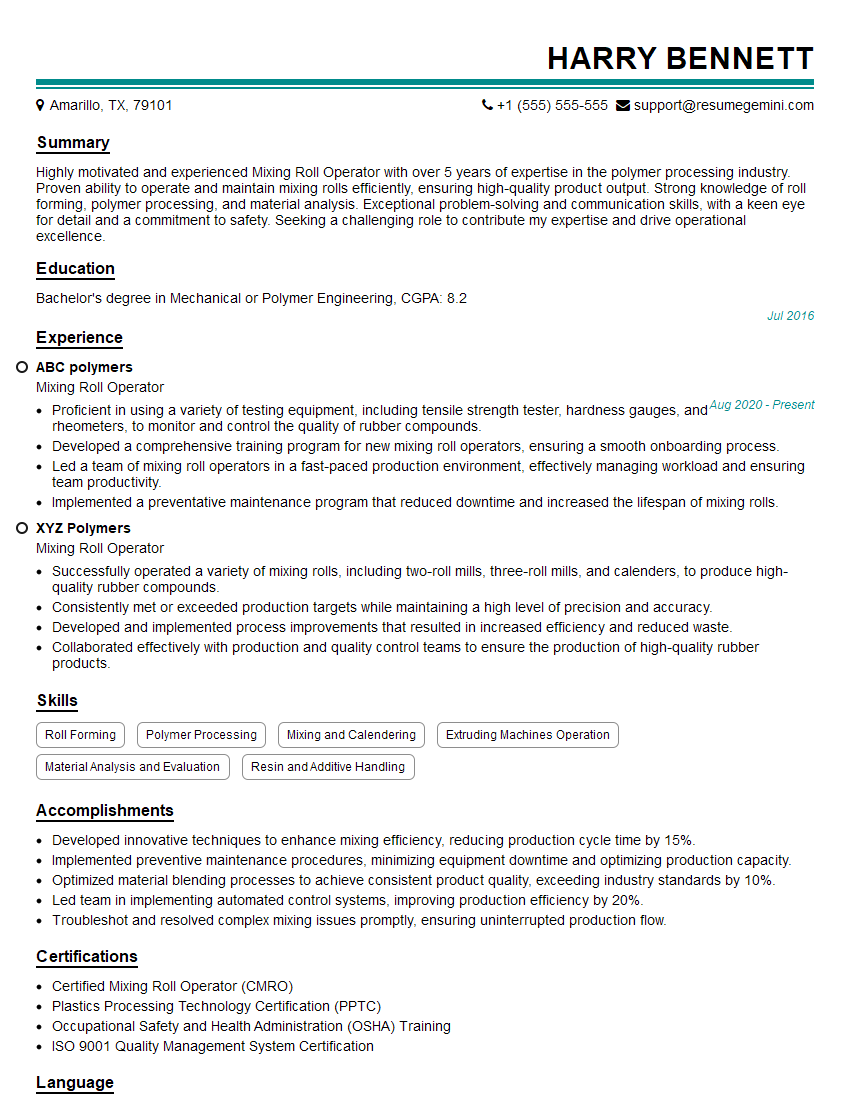

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixing Roll Operator

1. What are the key responsibilities of a Mixing Roll Operator?

As a Mixing Roll Operator, I would be responsible for a range of tasks, including:

- Operating mixing rolls to blend various ingredients according to specified formulations.

- Monitoring the mixing process to ensure proper consistency, texture, and quality of the blended materials.

2. What knowledge of mixing equipment is essential for a Mixing Roll Operator?

Technical Expertise

- Thorough understanding of the principles of mixing and the capabilities of different types of mixing equipment.

- Expert knowledge of mixing roll machinery, including its components, functions, and maintenance requirements.

Safety Measures

- In-depth knowledge of safety protocols and procedures related to operating mixing rolls, handling chemicals, and working in a manufacturing environment.

- Understanding of proper lockout/tagout procedures and emergency response protocols.

3. What quality control procedures should a Mixing Roll Operator follow?

To ensure the quality of the blended materials, I would adhere to the following quality control procedures:

- Regularly inspecting raw materials for quality and conformity to specifications.

- Monitoring the mixing process using appropriate instruments and techniques to ensure the desired consistency, texture, and quality are achieved.

- Conducting regular checks on equipment performance and calibration to maintain accuracy and prevent contamination.

- Maintaining detailed records of mixing parameters, including ingredients, mixing times, and equipment settings, for traceability and quality assurance.

4. How do you prioritize tasks and manage your time effectively when working as a Mixing Roll Operator?

To prioritize tasks and manage my time effectively, I would implement the following strategies:

- Create a daily or weekly schedule that outlines the tasks to be completed and allocates time accordingly.

- Prioritize tasks based on their urgency, importance, and deadlines.

- Break down complex tasks into smaller, manageable steps to avoid feeling overwhelmed.

- Utilize time management techniques such as the Pomodoro Technique to stay focused and avoid distractions.

- Delegate responsibilities to colleagues when appropriate to ensure timely completion of all tasks.

5. What maintenance procedures are crucial for Mixing Roll Operators to perform?

To ensure the smooth and efficient operation of mixing rolls, I would perform the following maintenance procedures:

- Regularly clean and inspect mixing rolls, blades, and other components for wear, damage, or contamination.

- Lubricate moving parts according to the manufacturer’s specifications to minimize friction and prevent premature wear.

- Calibrate and adjust equipment as needed to maintain accuracy and precision in mixing operations.

- Monitor equipment performance and identify potential issues early on to prevent breakdowns and minimize downtime.

- Follow established lockout/tagout procedures during maintenance to ensure safety and prevent accidents.

6. How do you ensure the safety of yourself and others while operating mixing rolls?

To ensure the safety of myself and others in the workplace, I would adhere to the following safety protocols:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs, when operating mixing rolls.

- Follow established lockout/tagout procedures before performing any maintenance or repairs on equipment.

- Maintain a clean and organized work area to prevent slips, trips, or falls.

- Be aware of the location of emergency exits and fire extinguishers in case of an emergency.

- Report any unsafe conditions, accidents, or near misses to supervisors immediately.

7. What troubleshooting techniques do you employ when experiencing issues with mixing rolls?

To troubleshoot issues with mixing rolls effectively, I would follow a systematic approach:

- Identify the problem clearly and gather information about the symptoms and conditions under which it occurs.

- Consult technical manuals and consult with experienced colleagues or supervisors for guidance.

- Perform a visual inspection of the equipment to identify any obvious damage or wear.

- Check electrical connections, fuses, and other components to ensure they are functioning properly.

- Clean and adjust components as necessary, and monitor the equipment to verify that the issue has been resolved.

8. How do you handle situations when you are working under pressure and deadlines?

When working under pressure and deadlines, I employ the following strategies:

- Stay calm and organized, and prioritize tasks based on their importance and urgency.

- Break down complex tasks into smaller, more manageable steps to avoid feeling overwhelmed.

- Communicate effectively with supervisors and colleagues to ensure everyone is aware of the deadlines and expectations.

- Utilize time management techniques to stay focused and avoid distractions.

- Seek support from colleagues or supervisors if I encounter any difficulties or obstacles.

9. What are some of the challenges you have faced as a Mixing Roll Operator and how did you overcome them?

One of the challenges I faced as a Mixing Roll Operator was ensuring consistent quality of blended materials while working with varying raw materials.

To overcome this challenge, I:

- Collaborated with suppliers to establish clear specifications and quality control measures for incoming raw materials.

- Implemented rigorous quality control procedures throughout the mixing process, including regular inspections and testing.

- Fine-tuned mixing parameters and equipment settings to optimize the mixing process for different types of raw materials.

As a result, I was able to consistently produce high-quality blended materials, meeting the required specifications and customer expectations.

10. Why are you interested in working as a Mixing Roll Operator in our company?

I am highly interested in the Mixing Roll Operator position at your company because:

- Your company’s reputation as a leader in the industry and commitment to quality aligns with my own values and aspirations.

- The opportunity to work with state-of-the-art mixing equipment and contribute to the production of high-quality products excites me.

- I am confident that my skills and experience as a Mixing Roll Operator would be a valuable asset to your team.

- I am eager to learn and grow within your company and contribute to its continued success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixing Roll Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixing Roll Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mixing Roll Operators are responsible for the smooth operation of mixing rolls, ensuring the production of high-quality products. Their key responsibilities include:

1. Operating Mixing Rolls

Setting up, monitoring, and adjusting mixing rolls to achieve optimal mixing results.

- Loading and unloading materials into and from the mixing rolls.

- Controlling temperature, speed, and mixing time to achieve desired product specifications.

2. Monitoring Equipment

Regularly inspecting mixing rolls for any signs of wear, damage, or malfunction.

- Performing basic maintenance and repairs as necessary.

- Reporting any equipment issues to supervisors or maintenance personnel.

3. Maintaining Production Standards

Ensuring that mixing processes adhere to established quality standards and safety protocols.

- Following written operating procedures and using appropriate personal protective equipment.

- Monitoring the quality of the mixed product and making adjustments as needed.

4. Troubleshooting and Problem-solving

Identifying and resolving any issues that may arise during the mixing process.

- Analyzing production data, identifying deviations, and implementing corrective actions.

- Working with supervisors to resolve complex technical or operational problems.

Interview Tips

To ace an interview for a Mixing Roll Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the industry by researching their operations, products, and market position.

- Visit the company website, read industry publications, and attend trade shows.

- Connect with company employees on LinkedIn and ask for insights into the role.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience with operating mixing rolls, monitoring equipment, and maintaining production standards.

- Quantify your accomplishments with specific examples and metrics.

- Explain how your skills and experience align with the job requirements.

3. Demonstrate Problem-Solving Abilities

Mixing Roll Operators are often required to troubleshoot and resolve issues. Showcase your problem-solving skills by providing examples.

- Describe a situation where you identified a problem, analyzed the root cause, and implemented a solution.

- Explain your approach to problem-solving and how it has benefited your previous employers.

4. Emphasize Safety and Quality

Mixing Roll Operators play a crucial role in ensuring product quality and safety. Highlight your commitment to these principles.

- Describe your experience in following safety protocols and maintaining a clean and organized work environment.

- Explain how you prioritize product quality and ensure that products meet established specifications.

Next Step:

Now that you’re armed with the knowledge of Mixing Roll Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mixing Roll Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini