Are you gearing up for an interview for a Mixing Tumbler Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mixing Tumbler Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

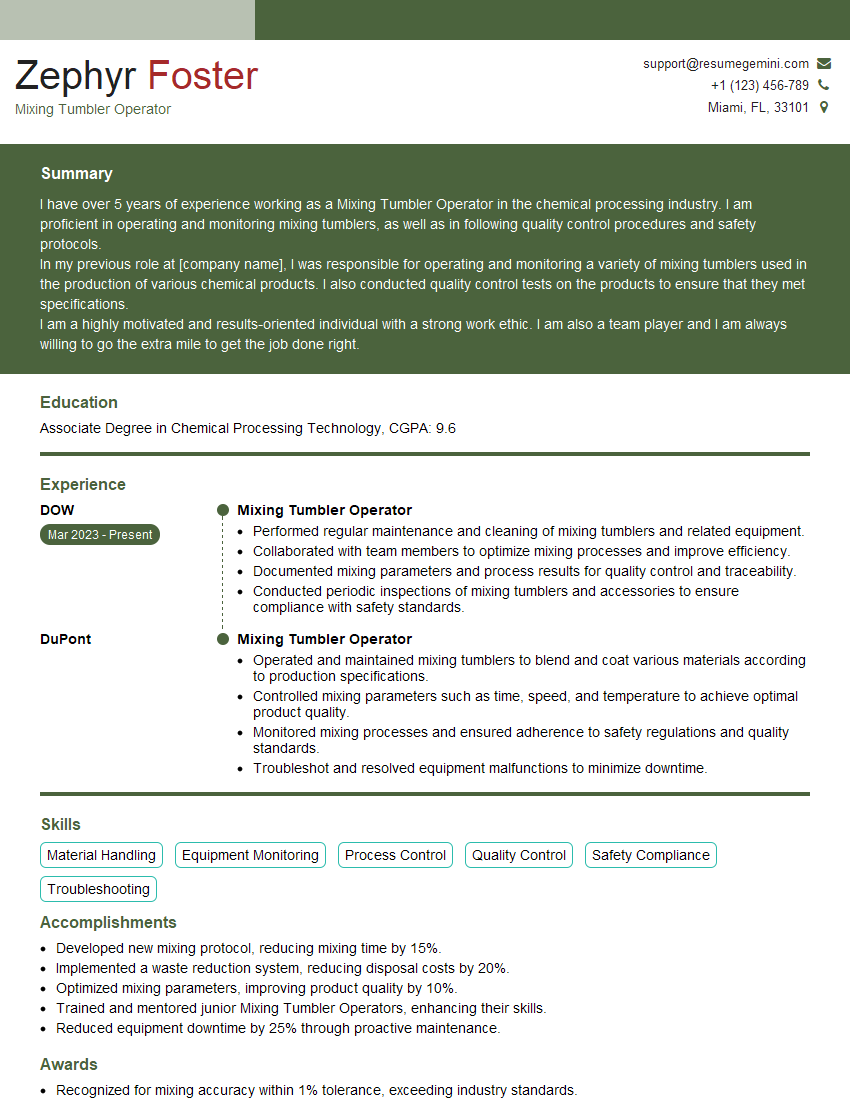

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixing Tumbler Operator

1. How would you determine the right amount of time to mix a batch of materials in a mixing tumbler?

- Consider the type of materials being mixed, their properties, and how they interact with each other.

- Calculate the optimal mixing time based on the desired level of mixing uniformity, as well as the equipment’s mixing rate.

2. What are some common problems that can occur during mixing, and how would you troubleshoot them?

Improper mixing:

- Verify that the correct materials and proportions are being used.

- Check if the mixing speed or time is adequate for the materials.

Material bridging or caking:

- Inspect the materials and equipment for any signs of moisture or clumping.

- Adjust the mixing speed or add flow agents to help disperse the materials.

3. What are some safety precautions you must take when operating a mixing tumbler?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Ensure that the tumbler is properly grounded and electrical connections are secure.

- Avoid touching moving parts or reaching into the tumbler while it is operating.

- Keep the work area clean and free of tripping hazards or spilled materials.

4. How would you ensure that the materials being mixed do not contaminate each other?

- Clean the tumbler and all equipment thoroughly before starting the mixing process.

- Segregate different materials and avoid mixing incompatible substances.

- Use separate mixing tools for different materials to prevent cross-contamination.

5. How would you maintain the mixing tumbler to ensure it operates efficiently?

- Regularly inspect and clean the tumbler’s interior and mixing paddles.

- Check and adjust the drive belts or chains to ensure proper tension and alignment.

- Lubricate moving parts according to the manufacturer’s guidelines.

- Monitor the tumbler’s temperature and vibration levels to prevent overheating or damage.

6. How would you handle a situation where the mixing tumbler malfunctions during operation?

- Immediately shut down the tumbler and disconnect the power supply.

- Identify the source of the malfunction and take necessary precautions to prevent further damage.

- Contact a qualified technician for repairs or troubleshooting.

- Document the incident and report it to the supervisor.

7. How would you optimize the mixing process to achieve the most homogenous mixture?

- Use proper mixing techniques such as rotating or tumbling the materials.

- Control the mixing speed and time to maximize mixing efficiency.

- Add mixing aids or surfactants to enhance the dispersion of particles.

8. What quality control measures would you implement to ensure the accuracy of the mixing process?

- Regularly test the mixed materials to verify their composition and uniformity.

- Maintain records and documentation of the mixing process parameters.

- Conduct periodic audits to assess the overall performance and compliance of the mixing operation.

9. How would you train new employees on the proper operation and maintenance of the mixing tumbler?

- Provide clear instructions and demonstrations on the operating procedures.

- Explain the importance of safety precautions and proper equipment handling.

- Supervise and evaluate new employees during hands-on training sessions.

- Provide written materials and training aids for ongoing reference.

10. How do you stay up-to-date on the latest advancements and best practices in mixing technology?

- Attend industry conferences and workshops.

- Read trade publications and research papers related to mixing technologies.

- Consult with experts and manufacturers to gain knowledge of new equipment and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixing Tumbler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixing Tumbler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mixing Tumbler Operator is responsible for operating and maintaining mixing tumblers used in industrial processes. They ensure that the machines operate efficiently and produce high-quality products. Here are some key job responsibilities:

1. Operation of Mixing Tumblers

Operate mixing tumblers to mix various materials according to specified formulations.

- Load and unload materials into the tumbler.

- Set and adjust machine parameters, such as speed, time, and temperature.

2. Quality Control

Monitor the mixing process to ensure that materials are mixed thoroughly and meet quality standards.

- Inspect the final product for consistency, color, and other quality attributes.

- Make adjustments to the mixing process as needed.

3. Maintenance and Troubleshooting

Perform routine maintenance on mixing tumblers to ensure optimal performance.

- Clean and lubricate machine components.

- Identify and troubleshoot any mechanical or electrical issues.

4. Health and Safety

Adhere to safety regulations and follow established procedures to prevent accidents.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Mixing Tumbler Operator position:

1. Research the Company and Position

Familiarize yourself with the company’s history, mission, and products. Research the specific Mixing Tumbler Operator role to understand the company’s expectations.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Practice answering questions about your experience, skills, and knowledge of mixing processes.

- Example Outline:

- Tell me about your experience operating mixing tumblers.

- How do you ensure the quality of the final product?

- Describe a time when you had to troubleshoot a mechanical issue with a mixing tumbler.

3. Highlight Your Skills

Emphasize your relevant skills, such as attention to detail, problem-solving abilities, and mechanical knowledge. Quantify your accomplishments whenever possible.

- Example:

- “I have 5 years of experience operating mixing tumblers in a manufacturing environment. During that time, I consistently met production targets while maintaining a high level of quality.”

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s growth plans, safety protocols, or opportunities for professional development.

5. Dress Professionally

First impressions matter. Dress appropriately for the interview, typically business casual attire.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mixing Tumbler Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.