Are you gearing up for an interview for a Mold Burner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mold Burner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

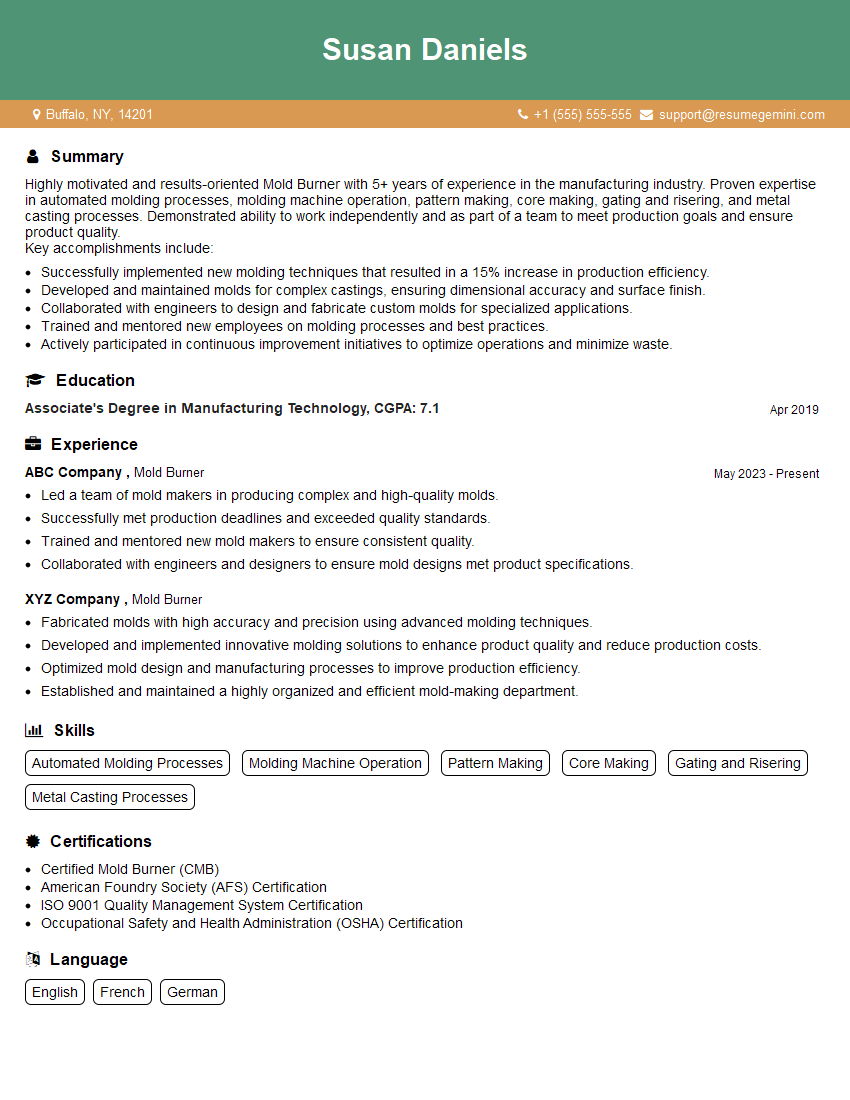

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Burner

1. What are the key responsibilities of a Mold Burner?

- Operate and monitor mold burning equipment to produce molds for various products.

- Inspect molds for defects and ensure they meet specifications.

- Clean and maintain mold burning equipment to ensure optimal performance.

- Follow safety protocols and regulations related to mold burning operations.

- Collaborate with other team members to ensure smooth production processes.

2. What safety precautions should be taken when operating mold burning equipment?

subheading of the answer

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure that the equipment is properly grounded and maintained.

- Operate the equipment in a well-ventilated area.

- Handle and store flammable materials safely.

- Follow established safety procedures and regulations.

subheading of the answer

- Be aware of potential hazards and take appropriate precautions.

- Report any safety concerns or incidents promptly.

- Stay informed about industry best practices and regulations.

- Participate in regular safety training and refreshers.

3. How do you ensure the quality of the molds produced?

- Inspect molds for defects such as cracks, warping, or contamination.

- Verify mold dimensions and specifications against design requirements.

- Use precision measuring tools and gauges to ensure accuracy.

- Follow established quality control procedures.

- Document inspection results and any necessary corrective actions.

4. What maintenance tasks are required for mold burning equipment?

- Clean and lubricate moving parts regularly.

- Inspect electrical components and wiring for damage or wear.

- Monitor and adjust temperature controls to ensure optimal performance.

- Calibrate and test safety devices and sensors.

- Perform regular preventative maintenance to minimize downtime.

5. What are the different types of molds used in manufacturing?

- Injection molds: Used to produce plastic parts.

- Die-casting molds: Used to produce metal parts.

- Lost-foam molds: Used to produce castings with complex geometries.

- Investment casting molds: Used to produce high-precision metal parts.

- Sand molds: Used to produce castings in large quantities.

6. What factors affect the choice of mold material?

- Type of product being produced.

- Quantity of parts required.

- Production speed and efficiency.

- Cost and availability of materials.

- Durability and lifespan of the mold.

7. Describe the different techniques used in mold burning?

- Gas burners: Use a mixture of gases to create a flame for burning molds.

- Electric burners: Use electrical resistance to generate heat for burning molds.

- Induction burners: Use electromagnetic induction to create heat for burning molds.

- Laser burners: Use a high-powered laser to burn molds with precision.

- Plasma burners: Use ionized gas to create a high-temperature plasma for burning molds.

8. How do you troubleshoot common problems encountered in mold burning?

- Uneven burning: Adjust burner settings or check for obstructions in the flame path.

- Mold defects: Inspect molds for damage or contamination, and adjust burning parameters if necessary.

- Equipment malfunctions: Check for electrical or mechanical problems, and refer to the manufacturer’s instructions for troubleshooting.

- Safety issues: Identify and address any potential hazards, and ensure compliance with safety protocols.

- Quality issues: Analyze production data and identify areas for improvement in mold quality and production efficiency.

9. How do you stay updated on the latest advancements in mold burning technology?

- Attend industry conferences and exhibitions.

- Read technical publications and journals.

- Participate in online forums and discussions.

- Collaborate with other professionals and share knowledge.

- Seek training and certification opportunities.

10. What are your strengths and weaknesses as a Mold Burner?

- Strengths:

- Thorough understanding of mold burning processes and techniques.

- Excellent attention to detail and quality control.

- Strong troubleshooting and problem-solving skills.

- Proven ability to work independently and as part of a team.

- Commitment to safety and compliance.

- Weaknesses:

- Limited experience with certain types of molds or materials.

- Need to improve communication skills when explaining technical concepts to non-technical personnel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Burners are pivotal in manufacturing processes, shaping molds and ensuring product quality. Their responsibilities encompass:

1. Mold Preparation

Thoroughly cleaning and inspecting molds before use, removing any imperfections that could compromise the final product.

- Utilizing specialized tools to polish and refinish molds, ensuring their optimal performance.

- Applying protective coatings to prevent corrosion and extend mold life.

2. Burning Process

Operating burners to heat molds to specified temperatures, ensuring even heat distribution and optimal curing of molded products.

- Monitoring and adjusting burner settings to maintain precise temperatures and achieve desired part characteristics.

- Inspecting molds during the burning process to identify and address any potential issues.

3. Quality Control

Performing regular inspections of molds and burned parts to ensure conformance to specifications and quality standards.

- Utilizing measuring tools and gauges to verify dimensions and tolerances, adhering to stringent quality requirements.

- Identifying and documenting any non-conformities or defects, ensuring timely corrective actions.

4. Equipment Maintenance

Maintaining and servicing burners and related equipment, including cleaning, lubrication, and minor repairs.

- Conducting regular inspections to identify potential issues and prevent breakdowns.

- Collaborating with maintenance teams to resolve more complex equipment issues.

Interview Tips

To ace a Mold Burner interview, it’s crucial to prepare effectively and showcase your relevant skills and experience. Here are some key tips:

1. Research the Company and Role

Thoroughly research the company you’re applying to, its products, and the specific role you’re interested in. This will help you tailor your answers and demonstrate your understanding of their business needs.

- Visit the company’s website and social media profiles to gather information about their history, culture, and industry standing.

- Review the job description carefully to identify the essential skills and qualifications required.

2. Practice Your Answers

Anticipate common interview questions and prepare concise and compelling answers that highlight your relevant experience and abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Quantify your results whenever possible to demonstrate the impact of your contributions.

3. Emphasize Safety and Attention to Detail

Mold Burners play a crucial role in ensuring the quality and safety of manufactured products. In your interview, stress your commitment to safety procedures and your meticulous attention to detail.

- Provide examples of how you’ve identified and resolved safety hazards in previous roles.

- Explain your quality control processes and how you ensure the accuracy of your work.

4. Showcase Your Technical Skills

Mold Burners must possess a solid understanding of burner operations and mold maintenance. Highlight your technical expertise in the interview.

- Describe your experience in operating different types of burners and controlling temperature settings.

- Explain your knowledge of mold materials, finishes, and inspection techniques.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the role and the company.

- Inquire about the company’s growth plans and how the Mold Burner position contributes to those goals.

- Ask about the training and development opportunities available for employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!