Are you gearing up for an interview for a Mold Forms Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mold Forms Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

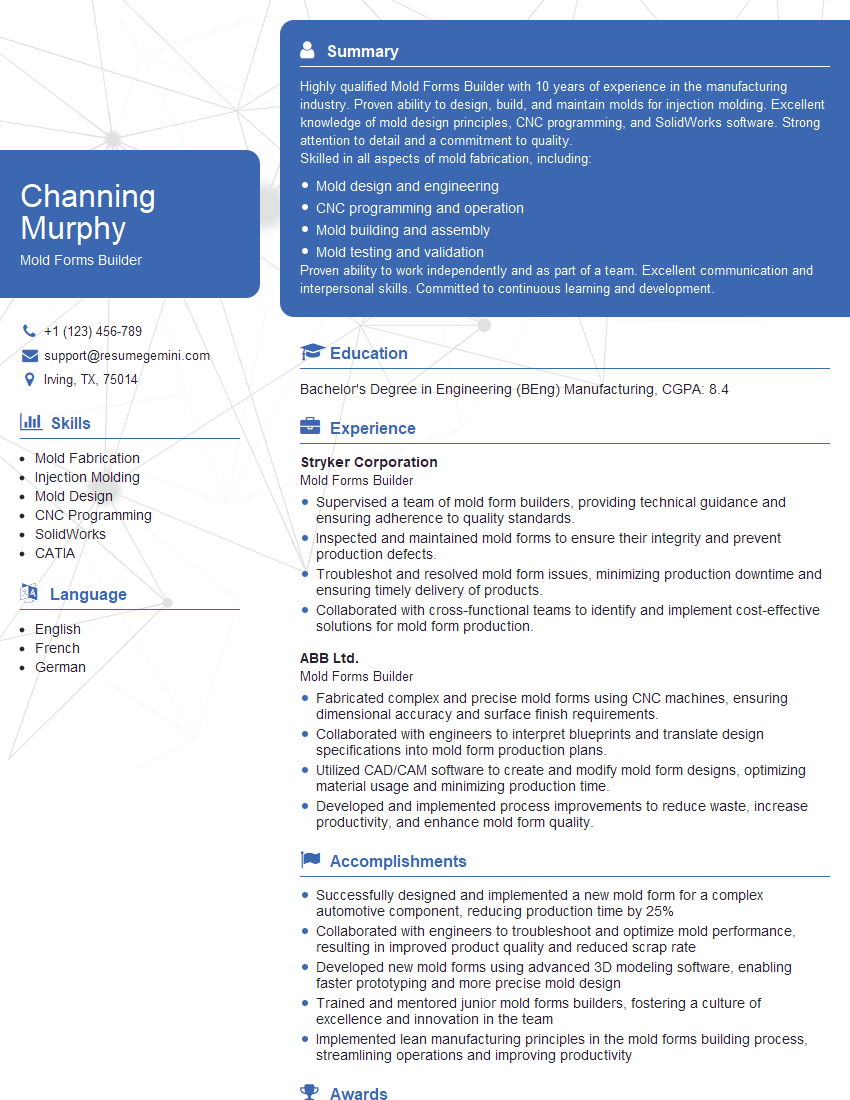

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Forms Builder

1. What are the key considerations when designing a mold form?

- Product geometry and dimensions

- Material properties of the molded part

- Type of molding process (e.g., injection molding, compression molding)

- Production volume and lead time requirements

- Cost and manufacturability considerations

2. What are the different types of mold materials and their properties?

Properties of steel molds:

- High strength and durability

- Good thermal conductivity

- Excellent wear resistance

Properties of aluminum molds:

- Lightweight and easy to machine

- Good thermal conductivity

- Lower strength and wear resistance than steel

3. How do you determine the appropriate gate location and size for a mold?

- Consider the flow characteristics of the molten plastic

- Optimize the fill pattern and reduce potential defects

- Balance the flow rates of different sections of the mold

- Minimize pressure drop and maximize part quality

4. How do you ensure proper cooling of the molded part in the mold?

- Design cooling channels in the mold

- Control the temperature of the cooling fluid

- Optimize the flow rate and pressure of the cooling fluid

- Use thermal insulation to minimize heat loss

5. What are the common troubleshooting techniques for mold design issues?

- Inspect the mold for signs of wear or damage

- Check the mold temperature and cooling system

- Review the gate design and flow simulation results

- Analyze the molded parts for defects and identify root causes

6. What are the latest trends and advancements in mold making technology?

- Use of advanced simulation software for mold design

- Development of new mold materials with improved properties

- Adoption of additive manufacturing for mold production

- Integration of sensors and IoT technology for mold monitoring

7. How do you stay updated with the latest industry practices and advancements?

- Attend industry conferences and workshops

- Read technical journals and articles

- Network with other mold designers and engineers

- Participate in online forums and discussion groups

8. What are your strengths and weaknesses as a Mold Forms Builder?

- Strong understanding of mold design principles

- Proficient in using mold design software

- Experience in designing molds for various applications

- Attention to detail and ability to work under pressure

- Limited experience in certain specialized molding processes

- Working on large-scale mold design projects

Strengths:

Weaknesses:

9. How do you manage multiple projects and meet deadlines effectively?

- Prioritize tasks based on importance and urgency

- Break down large projects into smaller, manageable chunks

- Utilize project management tools and techniques

- Communicate regularly with stakeholders to keep them informed of progress

- Delegate tasks to team members when necessary

10. Why are you interested in working for our company?

- Impressed by the company’s reputation and history in the industry

- Excited about the opportunity to work on challenging and innovative projects

- Interested in contributing to the company’s growth and success

- Confident in my ability to make a meaningful contribution to the team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Forms Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Forms Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Forms Builders are craftsmen responsible for designing, constructing, and repairing molds used in the manufacturing process. They use their knowledge of materials, fabrication techniques, and equipment to create molds that meet the specific requirements of the products being manufactured. Key job responsibilities of a Mold Forms Builder include:

1. Designing and Fabricating Molds

Mold Forms Builders work closely with engineers and designers to create molds that meet the specifications of the product being manufactured. They use a variety of materials, such as wood, metal, and plastic, to construct the molds. They also use specialized equipment, such as CNC machines, to create complex shapes and contours.

2. Inspecting and Maintaining Molds

Mold Forms Builders are responsible for inspecting and maintaining the molds they create. They check for defects, such as cracks or warpage, that could affect the quality of the products being manufactured. They also perform regular maintenance, such as cleaning and lubricating the molds, to ensure that they continue to operate properly.

3. Troubleshooting and Repairing Molds

Mold Forms Builders are also responsible for troubleshooting and repairing molds that have been damaged or worn out. They use their knowledge of materials and fabrication techniques to identify the problem and make the necessary repairs. They also work with other members of the manufacturing team to identify and correct any problems that may be affecting the quality of the products being manufactured.

4. Working with Other Members of the Manufacturing Team

Mold Forms Builders are part of a team of professionals who are responsible for the manufacturing process. They work closely with engineers, designers, and other members of the manufacturing team to ensure that the molds they create meet the specifications of the product being manufactured. They also work with quality control personnel to ensure that the products being manufactured meet the required standards.

Interview Tips

Preparing for an interview for a Mold Forms Builder position can be a daunting task, but there are a few things you can do to improve your chances of success.

1. Research the Company and the Position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company on their website and social media pages. You can also read articles about the company in trade publications and news outlets.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position, and to assess whether or not it is a good fit for you.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are respectful of their time and that you are serious about the position.

Next Step:

Now that you’re armed with the knowledge of Mold Forms Builder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold Forms Builder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini