Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molding Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molding Machine Tender so you can tailor your answers to impress potential employers.

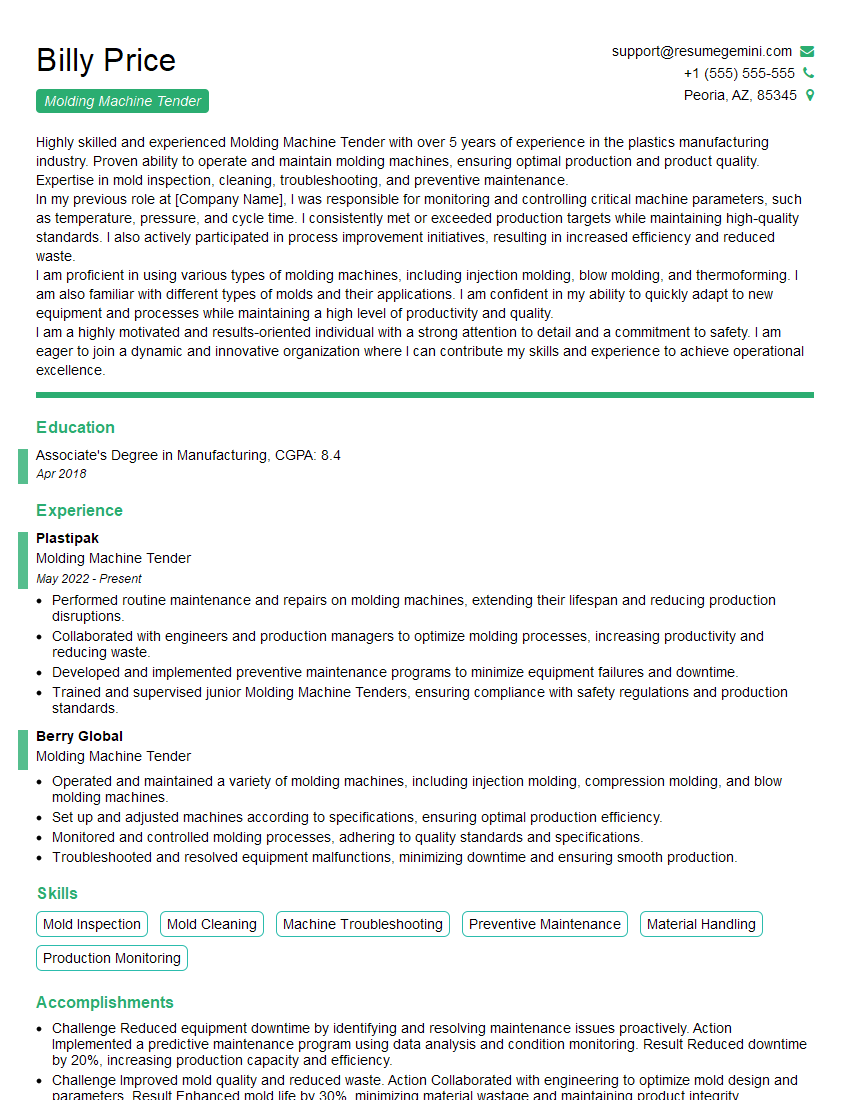

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Machine Tender

1. Explain the process of setting up a molding machine for a new job.

The process of setting up a molding machine for a new job involves several steps to ensure accurate and efficient production. Here’s a detailed explanation:

- Review work order and specifications: Carefully examine the work order and molding specifications to understand the requirements for the new job.

- Select and install mold: Choose the appropriate mold for the job and securely install it in the molding machine, ensuring proper alignment and clamping.

- Adjust machine settings: Based on the mold specifications and material properties, set the molding parameters such as temperature, pressure, cycle time, and injection speed.

- Calibrate sensors: Calibrate sensors for temperature, pressure, and mold position to ensure accurate monitoring and control during the molding process.

- Test run and fine-tuning: Perform a test run to check the molding process and make any necessary adjustments to optimize part quality and efficiency.

2. How do you troubleshoot common molding defects such as flash, sink marks, or voids?

Identifying the root cause

- Flash: Excess material escaping from mold parting lines or ejector pin holes. Causes include excessive injection pressure, worn mold, or improper mold alignment.

- Sink marks: Depressions on the molded part’s surface. Causes include insufficient injection pressure, improper cooling, or material shrinkage.

- Voids: Empty spaces within the molded part. Causes include trapped air, insufficient material flow, or improper injection speed.

Troubleshooting and solutions

- Flash: Adjust injection pressure, repair or replace worn mold, or ensure proper mold alignment.

- Sink marks: Increase injection pressure, optimize cooling system, or consider using a higher-strength material.

- Voids: Check for trapped air sources, increase injection speed, or modify mold design to improve material flow.

3. Describe the maintenance procedures you follow to keep molding machines in optimal condition.

Regular maintenance is crucial for maintaining the performance and longevity of molding machines. Here are key maintenance procedures:

- Daily inspections: Check for any leaks, unusual noises, or signs of wear on critical components.

- Weekly maintenance: Lubricate moving parts, clean sensors, and inspect hydraulic and electrical systems.

- Monthly maintenance: Perform more thorough inspections, such as checking mold alignment, calibrating sensors, and replacing worn parts.

- Scheduled overhauls: Conduct comprehensive overhauls at regular intervals to replace major components, perform deep cleaning, and ensure overall machine health.

4. Explain how you monitor and control the temperature of the mold during the molding process.

Temperature control is essential for producing high-quality molded parts. Here’s how I monitor and control the mold temperature:

- Temperature sensors: Install temperature sensors in the mold to monitor the temperature at critical points.

- Control system: Use a control system to regulate the temperature based on the desired settings.

- Heating and cooling systems: Utilize heating elements and cooling channels to adjust the mold temperature as needed.

- Regular monitoring: Continuously monitor the mold temperature and make adjustments as required to maintain optimum conditions.

5. Describe the safety procedures you follow when operating a molding machine.

Safety is paramount when operating molding machines. Here are key safety procedures I adhere to:

- PPE: Always wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Machine guarding: Ensure that all safety guards and interlocks are in place and functioning properly.

- Lockout/tagout: Follow lockout/tagout procedures before performing any maintenance or repairs.

- Emergency stop: Be familiar with the location and operation of the emergency stop button.

- Area clearance: Keep the work area clear of obstructions and ensure proper ventilation.

6. Explain how you handle and store molding materials to maintain their quality.

Proper handling and storage of molding materials are crucial for maintaining their quality and preventing contamination:

- Material receipt and inspection: Inspect incoming materials for damage or defects before storage.

- Storage conditions: Store materials in a dry, temperature-controlled environment to prevent degradation.

- FIFO method: Use the first-in, first-out (FIFO) method to ensure that materials are used in order of arrival.

- Moisture control: Employ moisture barriers or desiccants to prevent moisture absorption, especially for hygroscopic materials.

7. Describe the quality control procedures you follow to ensure the production of defect-free molded parts.

Quality control is essential to ensure that molded parts meet specifications and customer requirements:

- Visual inspection: Inspect molded parts for any visible defects, such as surface blemishes, dimensional variations, or color inconsistencies.

- Dimensional measurements: Use precision measuring tools to verify that parts meet the specified dimensions.

- Functional testing: Conduct functional tests to ensure that parts perform as intended, such as testing seals for leaks or electrical components for functionality.

- Statistical process control: Utilize statistical techniques to monitor and control the molding process, identifying and addressing any potential issues.

8. Explain how you collaborate with other departments, such as engineering and production planning, to optimize the molding process.

Collaboration is essential for efficient and effective molding operations:

- Engineering: Work with engineers to review part designs, identify potential molding challenges, and develop solutions to improve moldability.

- Production planning: Coordinate with production planning to optimize production schedules, minimize downtime, and ensure timely delivery of molded parts.

- Quality control: Collaborate with quality control personnel to establish and maintain quality standards, conduct inspections, and address any non-conformances.

9. Describe your experience in using different types of molding machines, such as injection molding machines, compression molding machines, or blow molding machines.

Experience with various molding machines is a valuable asset:

- Injection molding machines: Experience in operating injection molding machines, understanding the injection process, and troubleshooting common issues.

- Compression molding machines: Knowledge of compression molding techniques, including mold design and material preparation.

- Blow molding machines: Familiarity with blow molding processes, mold design, and parison control.

10. Explain your understanding of the latest advancements in molding technology, such as automation, robotics, and data analytics.

Stay up-to-date with molding technology advancements:

- Automation: Understanding the use of automated systems to improve efficiency, reduce labor costs, and enhance safety.

- Robotics: Experience in integrating robots into the molding process for tasks such as part handling, inspection, and packaging.

- Data analytics: Knowledge of data analytics tools for monitoring molding processes, identifying trends, and optimizing performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding machine tenders operate and monitor machines to mold plastic or rubber products. Their key responsibilities include:

1. Machine Operation and Monitoring

Molding machine tenders are responsible for operating and monitoring molding machines, which shape and form plastic or rubber products. They must ensure that the machines are running correctly and efficiently, and they must make adjustments as needed.

- Operate and monitor molding machines to ensure they are running efficiently.

- Adjust machine settings to ensure product quality meets specifications.

2. Mold Setup and Maintenance

Before starting the tending process, tenders must set up the mold and make sure it is in good working order. They must also perform any necessary maintenance to the mold and keep it clean.

- Set up and prepare molds for molding processes.

- Perform basic maintenance and repairs on molding machines and molds.

3. Quality Control

Molding machine tenders are responsible for ensuring that the products they produce meet quality standards. They must inspect the products for defects and make sure they are within the specifications.

- Inspect finished products for defects and ensure they meet specifications.

- Maintain quality control records and report any discrepancies to supervisors.

4. Production Output

Molding machine tenders must meet production quotas while maintaining quality standards. They must work efficiently and be able to troubleshoot any problems that may arise.

- Meet production quotas while maintaining quality standards.

- Identify and resolve production problems to minimize downtime.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help candidates ace their interview for a molding machine tender position:

1. Research the Company and Position

Before the interview, candidates should research the company and the specific position they are applying for. This will allow them to learn about the company’s culture, values, and goals, and to tailor their answers to the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read online reviews of the company to get an idea of what it’s like to work there.

2. Practice Common Interview Questions

Candidates should practice answering common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with molding machines?

- How do you handle working in a fast-paced environment?

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What is the company’s growth strategy for the next few years?

- What is the company’s culture like?

- What is the training program like for new employees?

- What is the starting salary for this position?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for the interview. Candidates should also arrive on time and be prepared to shake the interviewer’s hand firmly and make eye contact.

- Dress in business attire, such as a suit or dress pants and a button-down shirt.

- Arrive on time for your interview.

- Make eye contact and give the interviewer a firm handshake.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molding Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.