Feeling lost in a sea of interview questions? Landed that dream interview for Mud Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mud Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

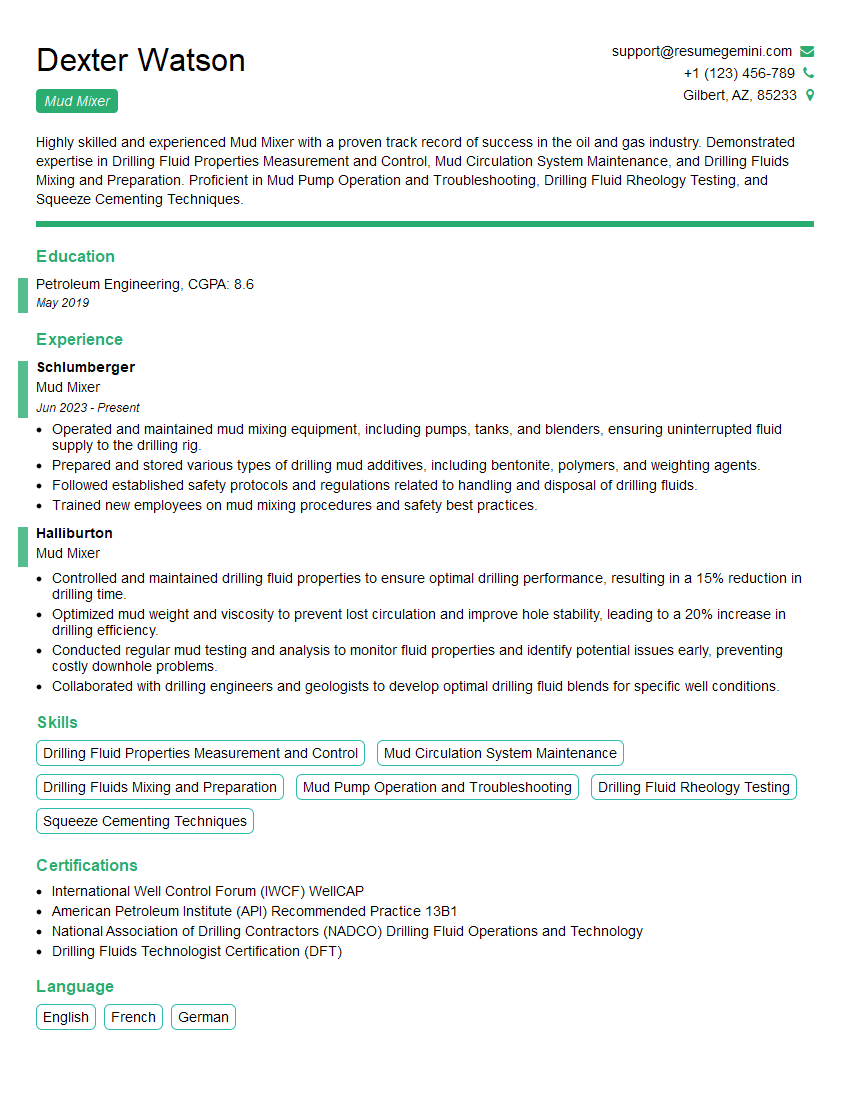

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mud Mixer

1. What are the different types of drilling fluids and their applications?

- Water-based fluids: These are the most common type of drilling fluid and are used in a wide variety of drilling applications. They are composed of water, clay, and various additives to control viscosity, density, and lubricity.

- Oil-based fluids: These fluids are used in more challenging drilling conditions, such as high-temperature and high-pressure environments. They are composed of a base oil, such as diesel or mineral oil, and various additives to control viscosity, density, and lubricity.

- Synthetic-based fluids: These fluids are a relatively new type of drilling fluid and offer several advantages over water-based and oil-based fluids. They are composed of synthetic hydrocarbons and various additives to control viscosity, density, and lubricity.

2. What are the key properties of drilling fluids?

Viscosity

- Viscosity is a measure of the resistance of a fluid to flow.

- It is an important property of drilling fluids as it affects the ability of the fluid to suspend cuttings, control fluid loss, and lubricate the drill string.

Density

- Density is a measure of the mass of a fluid per unit volume.

- It is an important property of drilling fluids as it affects the ability of the fluid to control formation pressure and prevent blowouts.

Lubricity

- Lubricity is a measure of the ability of a fluid to reduce friction between two surfaces.

- It is an important property of drilling fluids as it affects the ability of the fluid to reduce wear on the drill string and other drilling equipment.

3. What are the different methods of preparing drilling fluids?

- Batch mixing: This is the most common method of preparing drilling fluids.

- Continuous mixing: This method is used when large volumes of drilling fluid are required.

- In-field mixing: This method is used when drilling fluids need to be prepared on-site.

4. What are the different types of mud additives and their functions?

- Viscosifiers: These additives are used to increase the viscosity of drilling fluids.

- Weighting agents: These additives are used to increase the density of drilling fluids.

- Lubricants: These additives are used to reduce friction between the drill string and other drilling equipment.

- Fluid loss additives: These additives are used to reduce the amount of fluid that is lost to the formation.

- Corrosion inhibitors: These additives are used to protect the drill string and other drilling equipment from corrosion.

5. What are the different types of mud pumps and their applications?

- Centrifugal pumps: These pumps are used to circulate drilling fluids at low pressures.

- Positive displacement pumps: These pumps are used to circulate drilling fluids at high pressures.

- Mud motors: These pumps are used to power downhole tools, such as mud motors and rotary steerable systems.

6. What are the different types of mud tanks and their functions?

- Active tanks: These tanks are used to store drilling fluids that are being circulated through the wellbore.

- Reserve tanks: These tanks are used to store drilling fluids that are not being circulated.

- Mixing tanks: These tanks are used to mix drilling fluids.

7. What are the different types of mud agitators and their functions?

- Mechanical agitators: These agitators use mechanical means, such as paddles or impellers, to stir drilling fluids.

- Air agitators: These agitators use air to stir drilling fluids.

- Hydraulic agitators: These agitators use hydraulic pressure to stir drilling fluids.

8. What are the different types of mud screens and their functions?

- Shakers: These screens are used to remove large solids from drilling fluids.

- Desanders: These screens are used to remove sand from drilling fluids.

- Desilters: These screens are used to remove silt from drilling fluids.

9. What are the different types of mud testing equipment and their functions?

- Mud balance: This equipment is used to measure the density of drilling fluids.

- Viscometer: This equipment is used to measure the viscosity of drilling fluids.

- API filter press: This equipment is used to measure the fluid loss of drilling fluids.

10. What are the different types of mud logging equipment and their functions?

- Mud loggers: These personnel are responsible for monitoring the drilling fluids and recording data on the drilling process.

- Mud logging units: These units are used to house the mud logging equipment and provide a workspace for the mud loggers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mud Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mud Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mud Mixers are responsible for preparing and mixing drilling mud, a crucial component in the drilling process that lubricates the drill bit, carries cuttings to the surface, and maintains pressure in the wellbore.

1. Mud Preparation

- Measure and weigh different types of drilling mud components, including bentonite, barite, and polymers.

- Operate automated or manual mud mixing equipment to combine and blend components according to specified formulas.

- Monitor mud composition and make adjustments to maintain desired properties, such as viscosity, density, and pH level.

2. Mud Circulation

- Control mud pumps to circulate drilling mud through the wellbore.

- Monitor mud flow rates and pressures to ensure proper circulation and prevent potential problems.

- Identify and resolve issues related to mud flow, such as blockages or leaks.

3. Mud Testing

- Conduct routine tests on drilling mud to assess its properties and performance.

- Utilize specialized equipment, such as viscometers and pH meters, to evaluate viscosity, density, and other parameters.

- Record test results and make necessary adjustments to the mud composition to ensure optimal performance.

4. Equipment Maintenance

- Inspect and maintain mud mixing equipment, including pumps, tanks, and mixers.

- Perform routine cleaning and lubrication to ensure proper functioning and prevent breakdowns.

- Troubleshoot and resolve mechanical issues related to mud mixing operations.

5. Safety and Environmental Compliance

- Adhere to safety protocols and regulations related to drilling mud handling and disposal.

- Ensure proper handling and storage of drilling mud components to prevent environmental contamination.

- Follow waste management procedures for spent drilling mud and cuttings.

Interview Tips

Preparing thoroughly for a Mud Mixer interview is essential to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

- Learn about the drilling company’s operations, industry reputation, and specific drilling projects.

- Review the job description thoroughly to understand the key responsibilities, qualifications, and experience required.

- Prepare questions to ask the interviewer about the company and the role, demonstrating your interest and engagement.

2. Highlight Your Technical Skills

- Emphasize your knowledge of drilling mud composition, testing procedures, and equipment maintenance.

- Provide specific examples of your experience in preparing and circulating drilling mud, conducting mud tests, and troubleshooting equipment issues.

- Quantify your accomplishments whenever possible, using metrics such as mud flow rates, viscosity improvements, or cost savings.

3. Demonstrate Safety and Environmental Awareness

- Stress your commitment to safety in all aspects of drilling operations, including mud handling and disposal.

- Explain your knowledge of environmental regulations and best practices related to drilling mud management.

- Share examples of your proactive approach to minimizing environmental impact, such as implementing waste reduction programs or using biodegradable mud additives.

4. Show Teamwork and Problem-Solving Abilities

- Discuss your ability to work effectively as part of a drilling crew and collaborate with other team members.

- Describe instances where you successfully resolved mud-related problems, such as reducing mud viscosity or preventing mud losses.

- Emphasize your analytical skills and ability to troubleshoot and find solutions to technical challenges.

5. Dress Professionally and Arrive Prepared

- Dress appropriately for an industrial setting, wearing clean and sturdy work clothes or a company uniform.

- Be punctual and allow ample time to arrive at the interview location without any delays.

- Bring a copy of your resume, a pen and notebook to take notes, and any relevant certifications or licenses that you possess.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mud Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!