Are you gearing up for an interview for a Nailhead Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nailhead Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

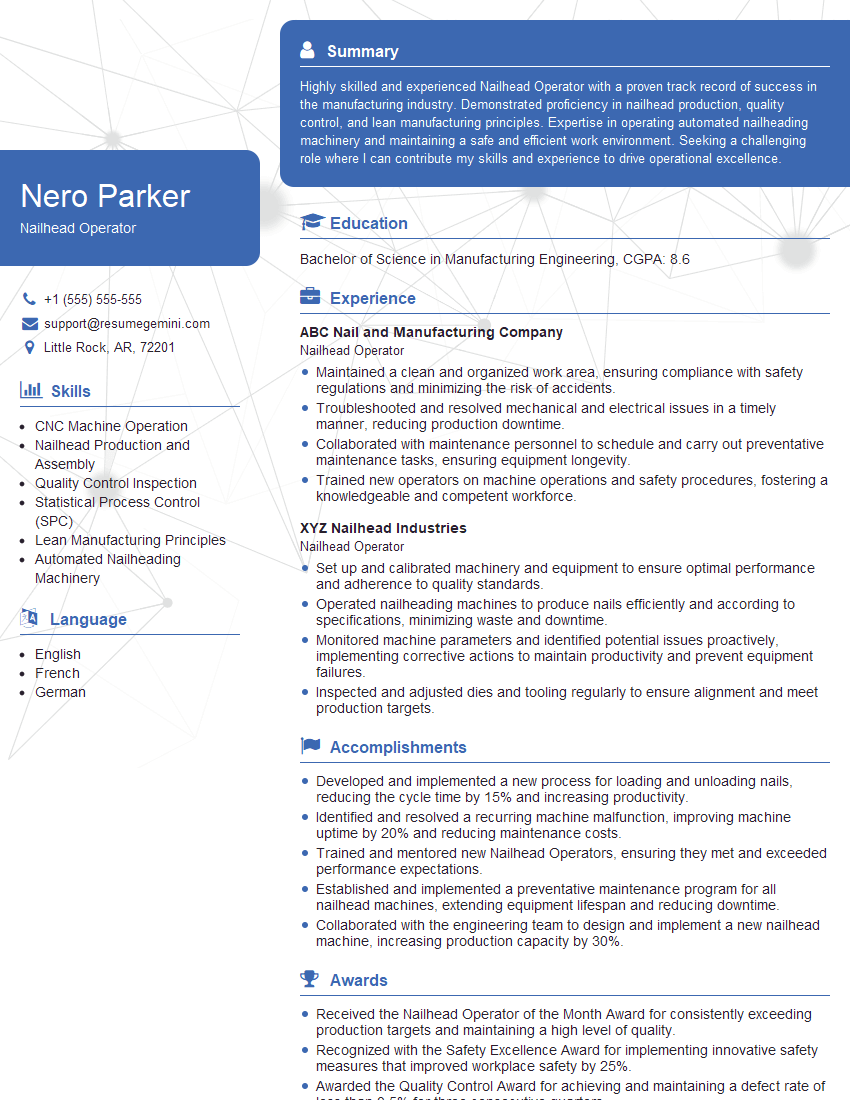

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nailhead Operator

1. What are the key responsibilities of a Nailhead Operator?

- Operate and maintain nailhead machines, which create fasteners from wire.

- Feed wire into the machine and adjust settings to produce nails of the specified size and shape.

- Inspect nails for quality and reject defective ones.

- Monitor the production process and make adjustments as needed to ensure smooth operation.

- Perform basic maintenance tasks on equipment, such as cleaning, lubrication, and minor repairs.

2. What are the different types of nailhead machines and their applications?

Types of nailhead machines

- Cold heading machines: Produce nails by forming the head and shank of the nail from a single piece of wire.

- Hot heading machines: Heat the wire before forming the head and shank, resulting in stronger nails.

- Thread rolling machines: Create threads on the shank of the nail, which provides a more secure hold.

Applications

- Construction: Framing, roofing, siding

- Manufacturing: Assembly, packaging

- Automotive: Trim, interior parts

- DIY projects: Home repairs, woodworking

3. What are the safety precautions that must be followed when operating a nailhead machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep the area around the machine clean and free of debris.

- Never reach into the machine while it is running.

- Be aware of moving parts and pinch points.

- Report any damage or malfunction to a supervisor immediately.

4. What are the common problems that can occur with nailhead machines and how can they be resolved?

- Problem: Nails not forming properly

- Possible resolution: Adjust machine settings, check wire quality, replace worn dies.

- Problem: Machine overheating

- Possible resolution: Check for lubrication, clean air vents, inspect electrical components.

- Problem: Nails breaking

- Possible resolution: Use higher-quality wire, adjust heat settings, check for cracks in dies.

5. How do you ensure the quality of nails produced by the nailhead machine?

- Inspect nails for proper dimensions, shape, and finish.

- Conduct regular performance tests on the machine to ensure optimal operation.

- Use quality control techniques, such as statistical process control, to monitor and improve production quality.

- Provide feedback to the maintenance team on any issues or improvements that could enhance nail quality.

6. What is your experience with different types of nailhead machines?

- Cold heading machines (e.g., National Machinery, Danobat)

- Hot heading machines (e.g., Ajax Tocco, Inductotherm)

- Thread rolling machines (e.g., Reed Thread Rolling, Macdowell)

7. How do you handle machine downtime?

- Immediately report downtime to a supervisor.

- Quickly identify the cause of the problem and implement solutions.

- Perform basic troubleshooting and repairs if possible.

- Communicate with maintenance personnel to schedule repairs and obtain replacement parts.

- Monitor production and adjust schedules to minimize the impact of downtime.

8. How do you stay updated with the latest advances in nailhead machine technology?

- Attend industry conferences and trade shows.

- Read industry publications and technical journals.

- Network with other nailhead operators and engineers.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers for product updates and technical support.

9. How do you ensure that the nailhead machine is properly maintained and calibrated?

- Follow the manufacturer’s recommended maintenance schedule.

- Perform regular inspections and lubrication of all components.

- Calibrate the machine using precision measuring instruments.

- Keep detailed records of all maintenance and calibration activities.

- Work closely with the maintenance team to address any issues or concerns.

10. What are your career goals and aspirations as a Nailhead Operator?

- To become a highly skilled and experienced Nailhead Operator.

- To improve my knowledge and skills in nailhead machine technology.

- To contribute to the efficiency and productivity of the manufacturing process.

- To advance my career within the industry and take on leadership roles.

- To stay abreast of the latest advancements in nailhead machine technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nailhead Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nailhead Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nailhead Operators are responsible for operating nailheading machines to produce nails. They also perform quality control checks, maintain equipment, and clean the work area.

1. Operate nailheading machines

Nailhead Operators must be able to safely and efficiently operate nailheading machines. This includes loading the machine with wire, setting up the machine, and operating the machine to produce nails.

- Load the machine with wire.

- Set up the machine.

- Operate the machine to produce nails.

2. Perform quality control checks

Nailhead Operators must be able to perform quality control checks on nails. This includes inspecting nails for defects, such as cracks, burrs, and bends. They must also be able to measure nails to ensure that they meet specifications.

- Inspect nails for defects.

- Measure nails to ensure that they meet specifications.

3. Maintain equipment

Nailhead Operators must be able to maintain equipment. This includes cleaning and lubricating machines, replacing worn parts, and making minor repairs.

- Clean and lubricate machines.

- Replace worn parts.

- Make minor repairs.

4. Clean the work area

Nailhead Operators must be able to clean the work area. This includes sweeping floors, wiping down machines, and removing scrap metal.

- Sweep floors.

- Wipe down machines.

- Remove scrap metal.

Interview Tips

Preparing for an interview can be daunting, but by following a few simple tips, you can increase your chances of success. Here are some tips to help you ace your interview for a Nailhead Operator position.

1. Research the company and the position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture, values, and goals. You should also learn as much as you can about the Nailhead Operator position, including the responsibilities, qualifications, and skills required.

- Visit the company’s website.

- Read articles about the company and the industry.

- Talk to people who work at the company.

- Review the job description.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. By practicing your answers to these questions, you can improve your delivery and increase your confidence.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with nailheading machines?

- How do you handle quality control?

- What is your availability?

3. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. For a Nailhead Operator position, you should dress in clean, comfortable clothing that is appropriate for a manufacturing environment.

- Wear clean, pressed clothing.

- Avoid wearing revealing or overly casual clothing.

- Choose closed-toe shoes that are comfortable to stand in.

- Consider wearing a hard hat and safety glasses to the interview.

4. Be confident and enthusiastic

During the interview, it is important to be confident and enthusiastic. This will show the interviewer that you are interested in the position and that you have the skills and abilities to be successful.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nailhead Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.