Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nitrate Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

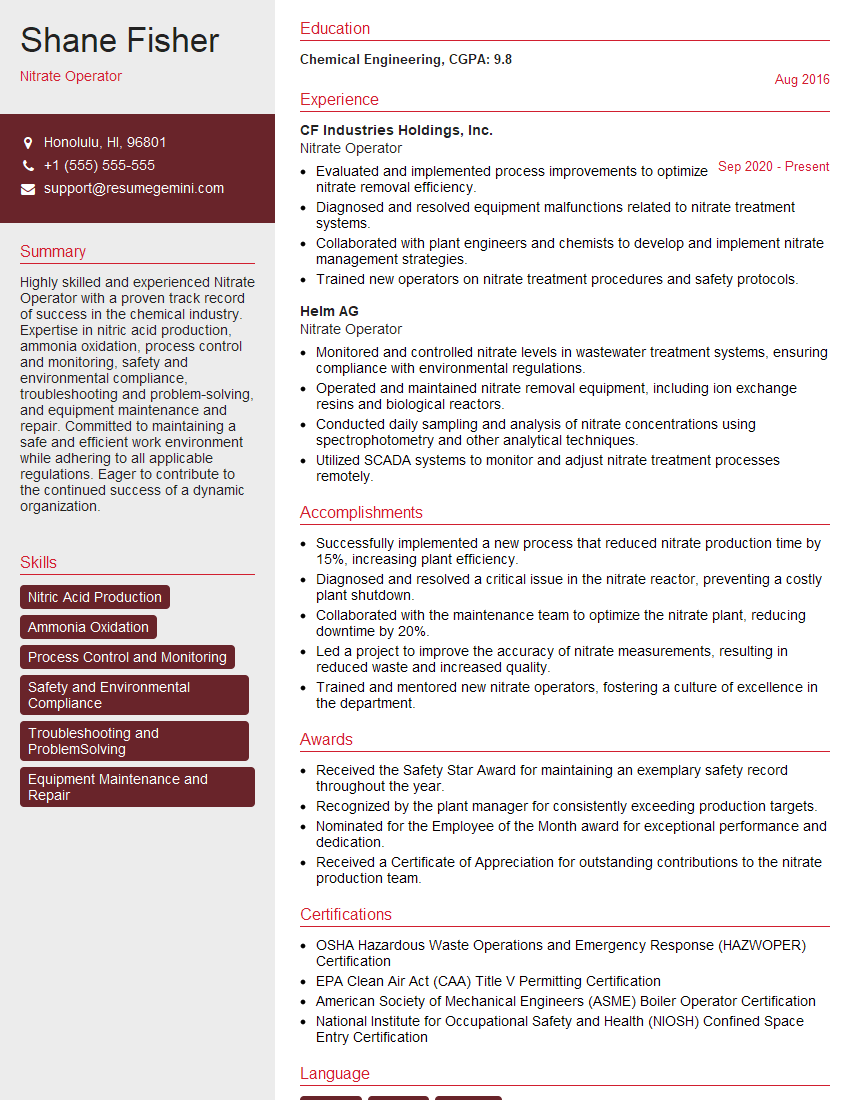

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nitrate Operator

1. Explain the role of a Nitrate Operator and its responsibilities?

As a Nitrate Operator, I am accountable for monitoring and controlling the production of nitric acid, ensuring optimal performance and safety within the plant. My responsibilities encompass:

- Monitoring and adjusting process parameters to maximize nitric acid production and maintain product quality.

- Operating and maintaining process equipment, including reactors, pumps, and pipelines.

- Performing routine inspections, troubleshooting, and repairs to ensure smooth plant operations.

- Coordinating with other operators and supervisors to ensure efficient and safe production.

- Adhering to established safety protocols, environmental regulations, and quality standards.

2. Describe the different types of nitrate production processes and their advantages and disadvantages?

Batch Process:

- Suitable for small-scale production.

- Requires manual operation and has a slower production rate.

- Less efficient compared to continuous processes.

Continuous Process:

- Ideal for large-scale production.

- Highly automated, resulting in increased efficiency and productivity.

- Requires specialized equipment and skilled operators.

3. Explain the principles of nitric acid production and the chemical reactions involved?

Nitric acid is produced through the Ostwald process, which involves three main reactions:

- Ammonia Oxidation: NH3 + 2O2 → NO + 3H2O

- Nitrogen Dioxide Formation: 2NO + O2 → 2NO2

- Nitric Acid Formation: 3NO2 + H2O → 2HNO3 + NO

4. Discuss the safety hazards associated with nitric acid production and the precautions that should be taken?

Nitric acid production involves potential hazards such as:

- Toxic and Corrosive: Nitric acid is highly corrosive and can cause severe burns and respiratory problems.

- Fire and Explosion: Nitric acid reacts vigorously with organic materials and can cause fires or explosions.

- Nitrogen Oxides: Nitrogen oxides released during the process can be toxic and corrosive.

Precautions include:

- Using proper personal protective equipment (PPE).

- Adhering to safety protocols and procedures.

- Maintaining proper ventilation and containment systems.

- Having emergency response plans in place.

5. Describe the quality control measures implemented to ensure the production of consistent and high-quality nitric acid?

Quality control measures include:

- Raw Material Analysis: Verifying the quality and purity of ammonia and air feedstocks.

- Process Monitoring: Continuously monitoring process parameters such as temperature, pressure, and flow rates.

- Product Testing: Regularly testing nitric acid samples to ensure it meets specified standards for purity, concentration, and impurities.

- Calibration and Maintenance: Calibrating and maintaining instruments and equipment to ensure accurate measurements.

6. Discuss the role of automation and instrumentation in modern nitrate production facilities?

Automation and instrumentation play a crucial role in optimizing production:

- Process Control: Automated systems monitor and adjust process parameters, enhancing efficiency and safety.

- Data Acquisition and Analysis: Instrumentation collects and analyzes data, providing insights for process optimization.

- Reduced Human Error: Automation reduces the risk of operator error, leading to increased consistency.

- Improved Safety: Automated systems can monitor and respond to potential safety hazards, improving overall plant safety.

7. Explain how you would troubleshoot a decrease in nitric acid production capacity?

Troubleshooting steps:

- Check Raw Materials: Verify the quality and availability of ammonia and air feedstocks.

- Examine Process Parameters: Analyze process conditions such as temperature, pressure, and flow rates for deviations.

- Inspect Equipment: Check for any issues with reactors, pumps, or pipelines that could affect production.

- Review Instrumentation: Ensure that instruments are calibrated and providing accurate readings.

- Consult Technical Documentation and Experts: Refer to manuals and consult with experienced personnel to identify potential causes and solutions.

8. Describe your experience in maintaining and repairing nitrate production equipment?

My experience in equipment maintenance and repair includes:

- Preventive Maintenance: Performing routine inspections and servicing to prevent breakdowns.

- Troubleshooting and Repairs: Identifying and resolving issues with reactors, pumps, and pipelines.

- Equipment Overhaul: Participating in scheduled overhauls to ensure optimal performance.

- Collaboration with Engineers and Technicians: Working closely with technical experts to diagnose and resolve complex issues.

9. Explain how you ensure compliance with environmental regulations and safety standards in a nitrate production facility?

Ensuring compliance involves:

- Monitoring Emissions: Continuously monitoring emissions to ensure they meet regulatory limits.

- Wastewater Treatment: Managing wastewater to minimize environmental impact.

- Adhering to Safety Protocols: Implementing and following established safety procedures to prevent accidents and protect personnel.

- Regular Audits and Inspections: Conducting internal audits and cooperating with external inspections to maintain compliance.

10. Describe how you would optimize the production of nitric acid to maximize yield and reduce costs?

Optimization strategies include:

- Process Optimization: Analyzing and adjusting process parameters to improve efficiency and reduce energy consumption.

- Equipment Upgrades: Installing new or upgraded equipment to enhance productivity and reduce maintenance costs.

- Raw Material Management: Managing inventory and purchasing raw materials at optimal prices.

- Byproduct Utilization: Exploring opportunities to utilize byproducts from the process to generate additional revenue streams.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nitrate Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nitrate Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Nitrate Operator is responsible for overseeing the production of nitrate fertilizer in an industrial setting. The key job responsibilities include:

1. Nitrate Production

Operate and maintain nitrate production equipment, including reactors, pumps, and pipelines.

- Monitor process parameters, such as temperature, pressure, and flow rates, to ensure optimal operation.

- Adjust process variables to maintain production targets and minimize waste.

2. Equipment Maintenance

Perform routine maintenance and repairs on equipment to ensure efficient operation.

- Inspect equipment for wear and tear, and order replacement parts as needed.

- Troubleshoot and resolve equipment problems to minimize downtime.

3. Quality Control

Monitor the quality of nitrate fertilizer produced, and make adjustments to the production process as needed.

- Collect samples for laboratory analysis to ensure compliance with quality standards.

- Identify and resolve any quality issues that arise.

4. Safety and Environmental Compliance

Ensure compliance with safety and environmental regulations in the workplace.

- Follow established safety protocols and procedures.

- Monitor environmental emissions and take measures to minimize impact.

Interview Tips

To prepare for a Nitrate Operator interview, candidates should focus on the following areas:

1. Technical Expertise

Highlight your knowledge of nitrate production processes, equipment operation, and quality control.

- Review the basics of nitrate chemistry and the principles of nitrate production.

- Familiarize yourself with the different types of nitrate production equipment and their functions.

2. Problem-Solving Skills

Demonstrate your ability to troubleshoot and resolve equipment problems efficiently.

- Prepare examples of situations where you identified and fixed equipment problems in a previous role.

- Discuss your approach to problem-solving and highlight your critical thinking skills.

3. Safety and Environmental Awareness

Emphasize your understanding of safety and environmental regulations in the workplace.

- Review the relevant safety protocols and environmental regulations for nitrate production facilities.

- Highlight your commitment to maintaining a safe and environmentally responsible work environment.

4. Communication and Teamwork

Showcase your ability to communicate effectively and work as part of a team.

- Prepare examples of how you communicated technical information to colleagues and supervisors.

- Discuss your experience in collaborating with others to achieve common goals.

Next Step:

Now that you’re armed with the knowledge of Nitrate Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Nitrate Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini