Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nut Sheller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

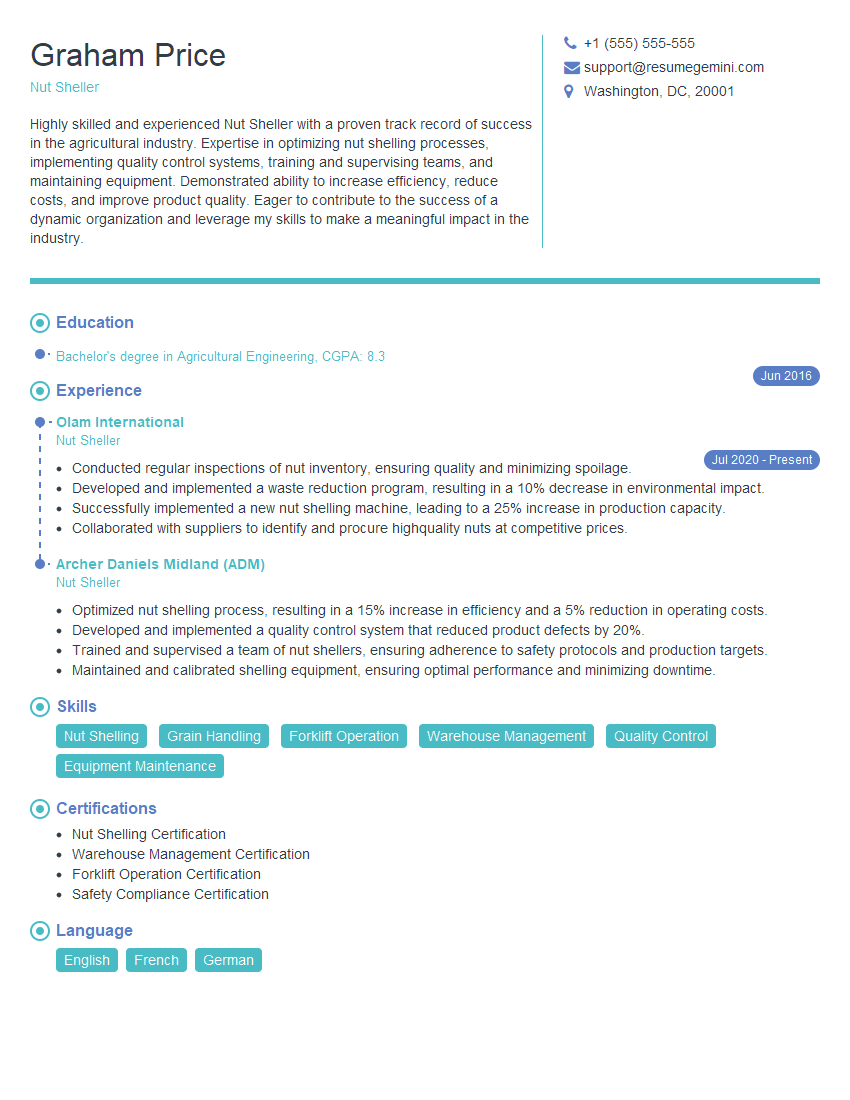

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nut Sheller

1. Explain the working principle of a nut sheller machine?

The working principle of a nut sheller machine involves the following steps:

- Feeding: Nuts are loaded into the hopper of the machine.

- Shelling: The nuts pass through a series of rotating drums or blades that crack and remove the shells.

- Separation: The shelled nuts are separated from the shells and other debris using screens or air currents.

- Cleaning: The shelled nuts are cleaned to remove any remaining debris or impurities.

- Grading: The shelled nuts may be graded by size or quality before packaging.

2. What are the different types of nut sheller machines available?

Electric Nut Shellers

- Suited for small-scale operations

- Require electrical power to operate

Hydraulic Nut Shellers

- More powerful and efficient than electric models

- Utilize hydraulics to crack the shells

Pneumatic Nut Shellers

- Use compressed air to remove the shells

- Suitable for large-scale commercial applications

3. What are the key factors to consider when selecting a nut sheller machine?

- Type of nuts: Different nut varieties require specific shelling mechanisms.

- Capacity: Choose a machine with a capacity that meets your production needs.

- Efficiency: Look for machines that maximize shelling efficiency and minimize waste.

- Durability: The machine should be made from durable materials to withstand heavy use.

- Cost: Consider the initial purchase price as well as ongoing maintenance and repair costs.

4. How do you ensure the quality of shelled nuts?

- Regular maintenance: Keep the sheller machine clean and well-maintained to prevent contamination.

- Calibration: Calibrate the machine regularly to ensure optimal shelling performance and minimize breakage.

- Quality control: Implement a quality control system to inspect the shelled nuts for damage or impurities.

- Storage: Store the shelled nuts properly to maintain their freshness and quality.

5. What are the common problems encountered in nut shelling and how do you troubleshoot them?

- Incomplete shelling: Check for dull blades or improper machine calibration.

- Nut breakage: Adjust the shelling pressure or use a different shelling mechanism.

- Shell contamination: Clean the machine thoroughly and ensure proper separation mechanisms.

- Low efficiency: Check for mechanical issues, such as worn bearings or faulty sensors.

6. How do you maintain and calibrate a nut sheller machine?

- Regular cleaning: Remove debris and contaminants from the machine regularly.

- Blade sharpening: Sharpen or replace dull blades to ensure optimal shelling performance.

- Calibration: Adjust the machine settings to ensure proper shelling pressure and efficiency.

- Lubrication: Lubricate moving parts to reduce friction and wear.

7. What advancements have been made in nut sheller technology?

- Automation: Modern nut shellers feature automated feeding and sorting systems.

- Laser sorting: Laser technology is used to detect and remove damaged or discolored nuts.

- Nitrogen use: Inert nitrogen gas is introduced to prevent oxidation and preserve nut quality.

- Energy efficiency: Improved designs and materials reduce energy consumption during operation.

8. What are the safety precautions that should be taken when operating a nut sheller machine?

- Follow instructions: Always read and understand the manufacturer’s operating instructions.

- Wear PPE: Use appropriate personal protective equipment, such as gloves, goggles, and earplugs.

- Inspect equipment: Check the machine thoroughly before each use for any damage or malfunction.

- Securely connect: Ensure that the machine is properly connected to a reliable power source.

9. How do you optimize the shelling process to maximize yield and minimize waste?

- Appropriate machine selection: Choose a machine that is suitable for the type of nuts being processed.

- Optimal settings: Adjust the shelling parameters, such as speed, pressure, and temperature, to optimize performance.

- Regular maintenance: Keep the machine in good working condition to prevent breakdowns and ensure consistent shelling.

- Proper feeding: Ensure a steady and even flow of nuts into the machine to avoid overfeeding or underfeeding.

10. Can you describe the latest trends in the nut shelling industry?

- Sustainability: Focus on reducing waste and energy consumption during shelling processes.

- Smart technology: Integration of IoT and AI for remote monitoring and data analysis.

- Artisan shelling: Niche market for handcrafted and small-batch nut shelling.

- Expansion into new markets: Growing demand for shelled nuts in emerging economies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nut Sheller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nut Sheller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nut Shellers are responsible for operating and maintaining nut shelling machines that extract the kernels from nuts. Their duties may vary depending on the size and nature of the operation, but some of the key responsibilities include:

1. Machine Operation

Operate nut shelling machines to remove shells from various types of nuts, such as almonds, walnuts, pistachios, and hazelnuts

- Load nuts into the machine and adjust settings to ensure optimal shelling efficiency

- Monitor the shelling process and make adjustments as needed to maintain desired kernel quality and yield

2. Machine Maintenance

Perform regular maintenance and cleaning of shelling machines to ensure optimal performance and prevent breakdowns

- Replace or repair worn or damaged parts, such as belts, conveyors, and shelling heads

- Lubricate and clean machine components to prevent rust and ensure smooth operation

3. Quality Control

Inspect shelled kernels for quality and remove any damaged or foreign objects to comply with food safety regulations

- Monitor kernel color, texture, and moisture content to ensure adherence to quality standards

- Sort and grade shelled kernels based on size, shape, and other quality characteristics

4. Production Monitoring

Maintain production records and monitor machine efficiency to optimize shelling operations

- Track the weight and volume of nuts processed per hour or shift

- Identify and address any production bottlenecks or inefficiencies to improve productivity

Interview Tips

To prepare for a Nut Sheller interview, you can consider the following tips and hacks:

1. Research the Company and Position

Familiarize yourself with the company’s values, products, and industry standing. Understand the specific responsibilities and requirements of the Nut Sheller position to tailor your answers accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating and maintaining nut shelling machines, as well as your experience in quality control and production monitoring. If applicable, mention any certifications or training programs you have completed.

3. Prepare for Behavioral Questions

Interviewers may ask questions about your work ethic, teamwork abilities, and problem-solving skills. Prepare anecdotes and examples that demonstrate your reliability, collaborative nature, and ability to handle challenges.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Inquire about the company’s growth plans, safety protocols, or opportunities for professional development.

5. Practice Your Answers

Consider preparing answers to common interview questions related to your skills, experience, and motivations. Practice delivering your responses clearly and concisely, highlighting your strengths and qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nut Sheller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!