Are you gearing up for a career in Operations and Maintenance Technican (O&M Technician)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Operations and Maintenance Technican (O&M Technician) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

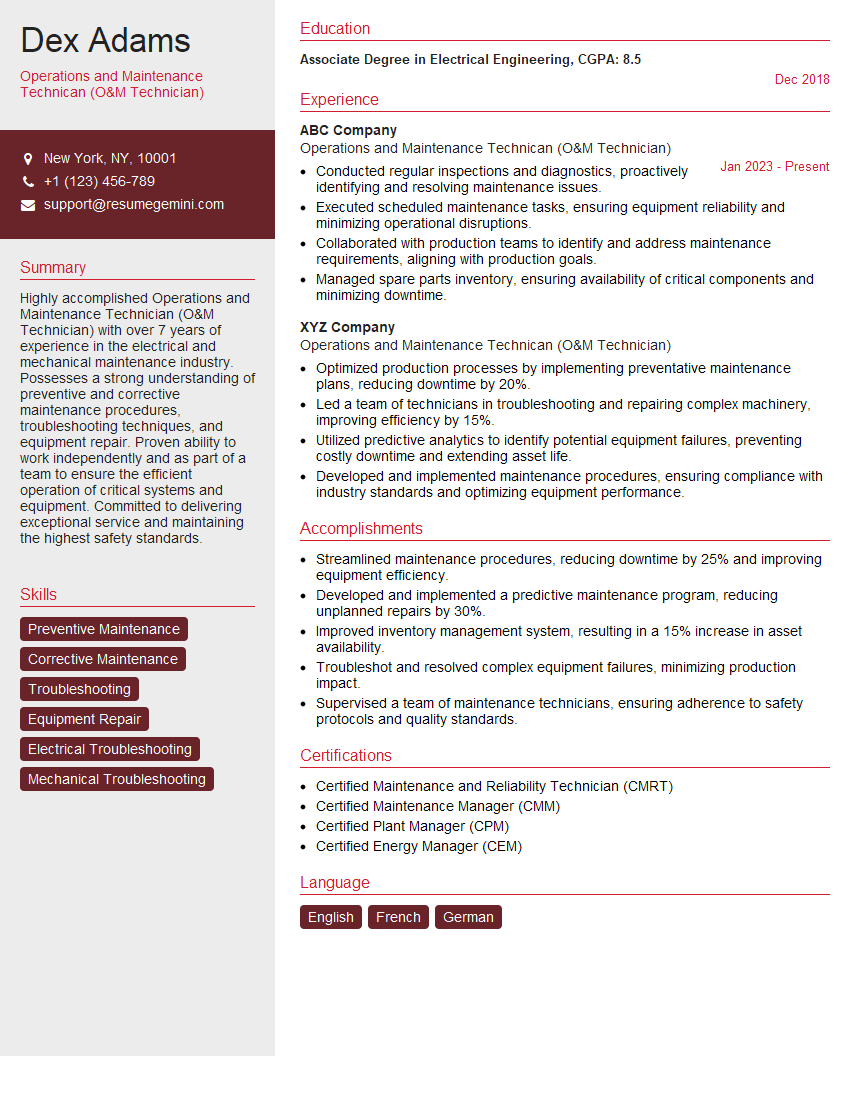

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operations and Maintenance Technican (O&M Technician)

1. Describe the steps involved in troubleshooting a malfunctioning piece of equipment.

- Identify the problem and its symptoms.

- Gather information about the equipment, its history, and any recent changes.

- Inspect the equipment for any obvious problems, such as loose wires, damaged components, or leaks.

- Use diagnostic tools and techniques to identify the root cause of the problem.

- Develop a plan to repair or replace the faulty component.

- Implement the repair or replacement plan and test the equipment to ensure that it is functioning properly.

- Document the troubleshooting process and findings for future reference.

2. What are the most common types of maintenance tasks performed on industrial equipment?

Preventive maintenance

- Regular inspections and cleaning.

- Lubrication and oil changes.

- Filter replacements.

- Tightening of bolts and connections.

- Calibration and adjustment of equipment.

Corrective maintenance

- Repairing or replacing faulty components.

- Troubleshooting and resolving equipment malfunctions.

- Overhauling and rebuilding equipment.

3. What are the key safety considerations when working on electrical equipment?

- Always disconnect the power source before working on electrical equipment.

- Use proper safety gear, such as insulated gloves, safety glasses, and hearing protection.

- Be aware of the location of electrical panels and circuit breakers.

- Never work on live electrical equipment.

- Follow all safety procedures and guidelines.

4. How do you maintain and calibrate measuring and testing equipment?

- Follow the manufacturer’s instructions for maintenance and calibration.

- Use certified calibration standards and equipment.

- Document all calibration procedures and results.

- Store and handle measuring and testing equipment properly.

5. Describe the different types of bearings used in industrial equipment and their applications.

- Rolling bearings – used in applications where there is high speed and low load.

- Plain bearings – used in applications where there is low speed and high load.

- Journal bearings – used in applications where there is high speed and high load.

- Thrust bearings – used in applications where there is axial load.

6. How do you align and tension belts and chains?

- Belts – use a belt tension gauge to measure the tension and adjust the tensioner accordingly.

- Chains – use a chain tensioner to adjust the tension.

7. What are the different types of lubrication systems used in industrial equipment?

- Manual lubrication – involves manually applying lubricant to equipment components.

- Automatic lubrication – uses a pump or dispenser to automatically apply lubricant to equipment components.

- Centralized lubrication – uses a network of pipes and valves to distribute lubricant to multiple equipment components.

8. How do you troubleshoot and repair hydraulic systems?

- Identify the problem and its symptoms.

- Inspect the hydraulic system for any obvious problems, such as leaks, loose connections, or damaged components.

- Use diagnostic tools and techniques to identify the root cause of the problem.

- Develop a plan to repair or replace the faulty component.

- Implement the repair or replacement plan and test the hydraulic system to ensure that it is functioning properly.

9. What are the different types of welding processes used in industrial maintenance?

- Arc welding – uses an electric arc to melt the metal and create a weld.

- MIG welding – a type of arc welding that uses a continuously fed wire electrode.

- TIG welding – a type of arc welding that uses a non-consumable tungsten electrode.

- Gas welding – uses a flame to melt the metal and create a weld.

10. How do you maintain and troubleshoot compressed air systems?

- Inspect the air compressor and its components regularly.

- Change the air filter and oil regularly.

- Check the air pressure and flow rate regularly.

- Troubleshoot any problems with the air compressor or its components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operations and Maintenance Technican (O&M Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operations and Maintenance Technican (O&M Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Operations and Maintenance Technicians perform a wide range of duties to ensure the efficient running of their organization. Their responsibilities can vary depending on the industry and the specific organization they work for, but some general key job responsibilities include:

1. Inspection and Maintenance

Inspecting equipment and systems to ensure they are functioning properly and safely.

- Conducting routine maintenance tasks, such as lubrication, filter changes, and cleaning.

- Troubleshooting and repairing equipment and systems.

2. Equipment and System Operation

Operating equipment and systems to ensure they are running efficiently and safely.

- Monitoring equipment and systems to identify any potential problems.

- Adjusting equipment settings to optimize performance.

3. Safety and Compliance

Ensuring that all operations and maintenance activities are conducted safely and in compliance with regulations.

- Following established safety protocols.

- Identifying and mitigating potential hazards.

- Keeping up to date on industry regulations and best practices.

4. Troubleshooting and Repair

Troubleshooting and repairing equipment and systems when they fail or malfunction.

- Identifying the cause of the problem.

- Repairing or replacing the damaged or faulty components.

- Testing and calibrating equipment and systems after repairs.

Interview Tips

Preparing for an Operations and Maintenance Technician interview can help you put your best foot forward and increase your chances of landing the job. Here are some tips to help you prepare:

1. Research the company and position

Before your interview, take some time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a candidate. You can find this information on the company’s website, LinkedIn, or other online sources.

2. Practice your answers to common interview questions

There are several common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice answering these questions out loud so that you can deliver your answers confidently and concisely.

3. Highlight your skills and experience

When you’re answering interview questions, emphasize your skills and experience that are relevant to the position you’re applying for. For example, if you have experience in troubleshooting and repairing equipment, be sure to mention that in your answer to the question “What are your strengths?”

4. Be prepared to talk about your safety experience

Safety is a critical aspect of Operations and Maintenance Technician jobs. In your interview, you’ll likely be asked about your safety experience and knowledge. Be prepared to discuss your experience with safety protocols and regulations, and how you ensure that you and your colleagues are working safely.

Next Step:

Now that you’re armed with the knowledge of Operations and Maintenance Technican (O&M Technician) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Operations and Maintenance Technican (O&M Technician) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini