Feeling lost in a sea of interview questions? Landed that dream interview for Optical Fabrication Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Optical Fabrication Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

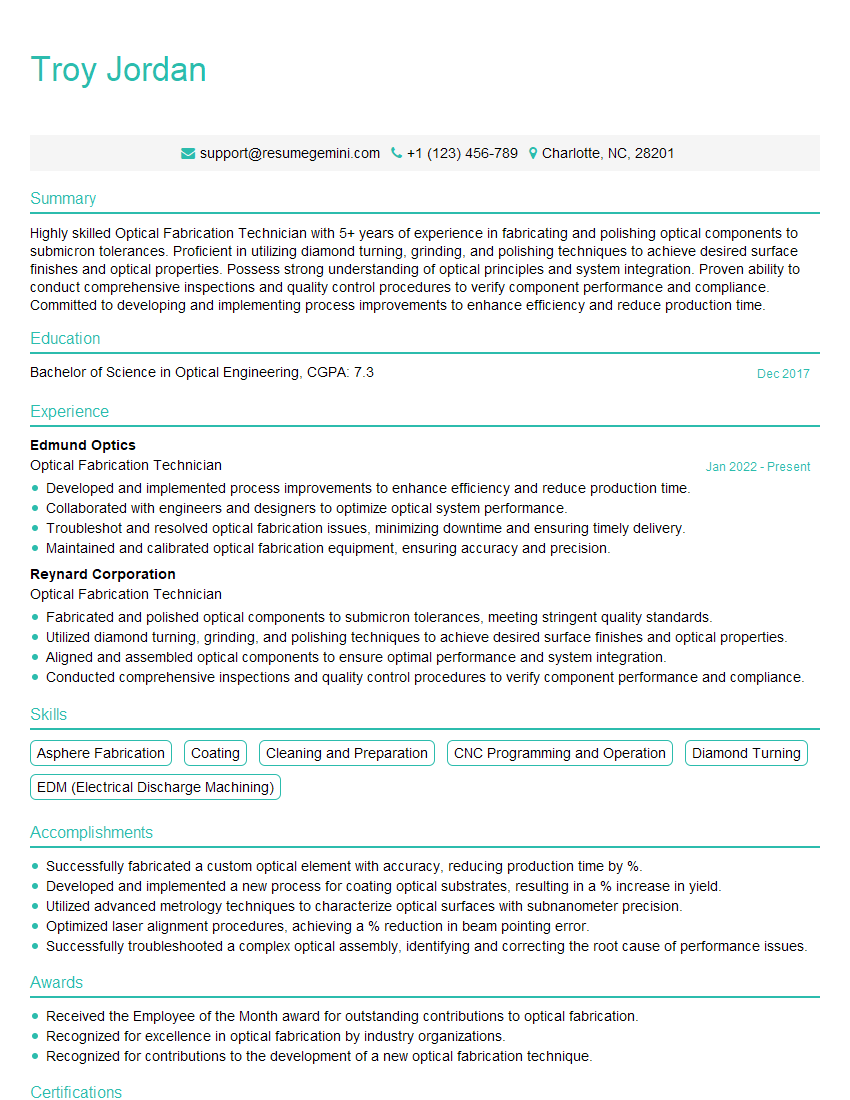

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Fabrication Technician

1. Explain the process of optical component fabrication.

Optical component fabrication involves several key steps:

- Design and specification: Determine the optical properties, dimensions, and tolerances of the component.

- Material selection: Choose the appropriate optical material based on its refractive index, dispersion, and other optical properties.

- Substrate preparation: Prepare the substrate by cleaning, polishing, and coating it with anti-reflection or other functional layers.

- Lens or optic shaping: Use techniques such as grinding, polishing, and diamond turning to shape the lens or optic to precise dimensions.

- Inspection and testing: Perform optical inspections and measurements to ensure the component meets specifications.

2. Describe the different types of optical fabrication techniques.

Optical fabrication techniques include:

- Grinding: Abrasive materials are used to remove material and shape the lens or optic.

- Polishing: Fine abrasives are used to smooth and polish the surface to reduce scattering and improve optical quality.

- Diamond turning: A single-point diamond tool is used to precisely shape and polish complex optical surfaces.

- Molding: Molten glass or plastic is pressed into a mold to create optical components with aspheric or other non-spherical shapes.

- Replication: A master optic is used to create a replica using materials such as polymers or metals.

3. What are the key quality control measures in optical fabrication?

Quality control measures in optical fabrication include:

- Visual inspection: Checking for scratches, defects, or contamination.

- Dimensional measurements: Using calipers, micrometers, or interferometers to verify dimensions.

- Optical testing: Using instruments such as interferometers, spectrophotometers, and reflectometers to measure optical properties.

- Environmental stress testing: Exposing the component to extreme temperatures, humidity, or vibration to evaluate its durability.

- Statistical process control: Monitoring and analyzing production processes to identify and minimize defects.

4. How do you ensure the accuracy and precision of optical components?

To ensure accuracy and precision:

- Use calibrated equipment: Regularly calibrate measuring and testing instruments.

- Follow strict production processes: Implement and adhere to documented procedures.

- Control environmental conditions: Maintain a clean and stable production environment.

- Inspect and test at multiple stages: Perform inspections and measurements throughout the fabrication process.

- Utilize advanced metrology techniques: Employ techniques such as interferometry or coordinate measuring machines (CMMs).

5. How do you handle and store optical components to prevent damage?

To handle and store optical components safely:

- Wear gloves and cleanroom attire: Minimize contamination and fingerprints.

- Use clean containers and packaging: Protect components from scratches and dust.

- Store in a controlled environment: Maintain appropriate temperature and humidity levels.

- Handle components carefully: Avoid touching or applying excessive force.

- Inspect components before use: Check for any damage or contamination before using them in optical systems.

6. Describe your experience with optical testing and evaluation techniques.

Optical testing and evaluation techniques I have experience with include:

- Interferometry: Using interferometers to measure surface flatness, wavefront distortion, and other optical properties.

- Spectrophotometry: Measuring the transmission or reflection of light over a range of wavelengths.

- Reflectometry: Evaluating the reflectance or scattering of light from optical surfaces.

- MTF and PSF measurement: Assessing the image quality of optical systems using Modulation Transfer Functions (MTFs) and Point Spread Functions (PSFs).

- Environmental testing: Conducting stress tests to evaluate the performance of optical components under extreme conditions.

7. What is the importance of optical coatings in optical fabrication?

Optical coatings are crucial in optical fabrication because they:

- Enhance optical performance: Improve light transmission, reflection, or polarization.

- Reduce losses: Minimize absorption or scattering of light.

- Provide functional properties: Enable special optical effects, such as anti-reflection, color filters, or beamsplitters.

- Increase durability: Protect optical surfaces from damage or environmental factors.

- Tailor optical properties: Customize the optical properties of components for specific applications.

8. How do you stay up-to-date with advancements in optical fabrication technology?

To stay updated on advancements in optical fabrication technology:

- Attend industry conferences and workshops: Network with experts and learn about new techniques.

- Read technical journals and research papers: Stay informed about the latest research and developments.

- Engage in professional development: Participate in training programs and certifications.

- Collaborate with research institutions: Establish partnerships for knowledge sharing and innovation.

- Follow industry news and trends: Monitor news sources and online forums for updates.

9. How would you troubleshoot an optical component that is not meeting specifications?

To troubleshoot an optical component that is not meeting specifications:

- Identify the problem: Perform inspections and tests to determine the root cause of the issue.

- Analyze the fabrication process: Review the production steps and identify any potential errors.

- Check equipment calibration: Ensure that measuring and testing equipment is calibrated and functioning properly.

- Investigate environmental factors: Consider the effects of temperature, humidity, or other environmental conditions.

- Consult with colleagues or experts: Seek advice from experienced professionals or optical engineers.

10. How do you ensure that optical components are manufactured to meet customer specifications and industry standards?

To ensure that optical components meet customer specifications and industry standards:

- Establish clear specifications: Work with customers to define detailed optical requirements and tolerances.

- Follow standardized production processes: Implement documented procedures that adhere to industry best practices.

- Implement rigorous quality control: Conduct inspections and testing at various stages of production.

- Maintain traceability: Track the production history of each component for quality assurance purposes.

- Obtain certifications and accreditations: Comply with industry standards and certifications, such as ISO 9001.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Fabrication Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Fabrication Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Optical Fabrication Technician, as a member of a team of scientists and engineers, is responsible for the fabrication and assembly of optical components and systems, including lenses, mirrors, and other optical elements.

1. Fabrication of Optical Components

The technician must be able to follow detailed instructions and drawings to fabricate optical components to precise specifications. This may involve using a variety of tools and equipment, such as lathes, mills, and grinders.

- Manufacture and assemble optical components and systems, such as lenses, mirrors, and prisms, according to specifications

- Follow detailed instructions and drawings to fabricate optical components to precise specifications

- Use a variety of tools and equipment, such as lathes, mills, and grinders, to fabricate optical components

2. Assembly of Optical Systems

The technician must also be able to assemble optical systems, such as telescopes, microscopes, and lasers. This requires a thorough understanding of the principles of optics and the ability to work with precision.

- Assemble optical systems, such as telescopes, microscopes, and lasers, according to specifications

- Calibrate and test optical systems to ensure that they meet specifications

- Troubleshoot and repair optical systems

3. Maintenance of Optical Equipment

The technician is also responsible for the maintenance of optical equipment. This includes cleaning, adjusting, and repairing optical components and systems.

- Maintain optical equipment, such as microscopes and telescopes

- Clean, adjust, and repair optical components and systems

- Inspect optical equipment to identify and resolve any problems

4. Other Responsibilities

In addition to the above responsibilities, the technician may also be responsible for:

- Developing and implementing new fabrication techniques

- Conducting research on new optical materials and technologies

- Training new employees

Interview Tips

To help candidates ace the interview for an Optical Fabrication Technician position, here are some interview tips and preparation hacks:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website to learn about their history, products, and services.

- Read reviews of the company on Glassdoor or other job boards to get an idea of the company culture and work environment.

- Look up the specific position you are applying for on the company’s website or on job boards. This will give you a good idea of the specific requirements of the position, including the skills, experience, and education required.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked in an interview for an Optical Fabrication Technician position. It is helpful to practice answering these questions in advance so that you can feel confident and prepared during the interview.

- Tell me about your experience in optical fabrication.

- What are your strengths and weaknesses as an optical fabrication technician?

- Why are you interested in this position?

- What are your salary expectations?

- Do you have any questions for me?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position, and to assess whether the company is a good fit for you.

- What are the biggest challenges facing the optical fabrication industry today?

- What are the company’s goals for the next year? What are the company’s long-term goals?

- What is the company culture like? What are the company’s values?

- What are your expectations for the successful candidate in this position?

- What is the next step in the interview process?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are taking the interview seriously.

- Dress in business casual attire.

- Arrive for your interview on time.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and your experience, and let the interviewer see the passion you have for optical fabrication.

- Be yourself and be confident.

- Be passionate about optical fabrication.

- Show the interviewer that you are eager to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Optical Fabrication Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!