Are you gearing up for an interview for a Panel Beater position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Panel Beater and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

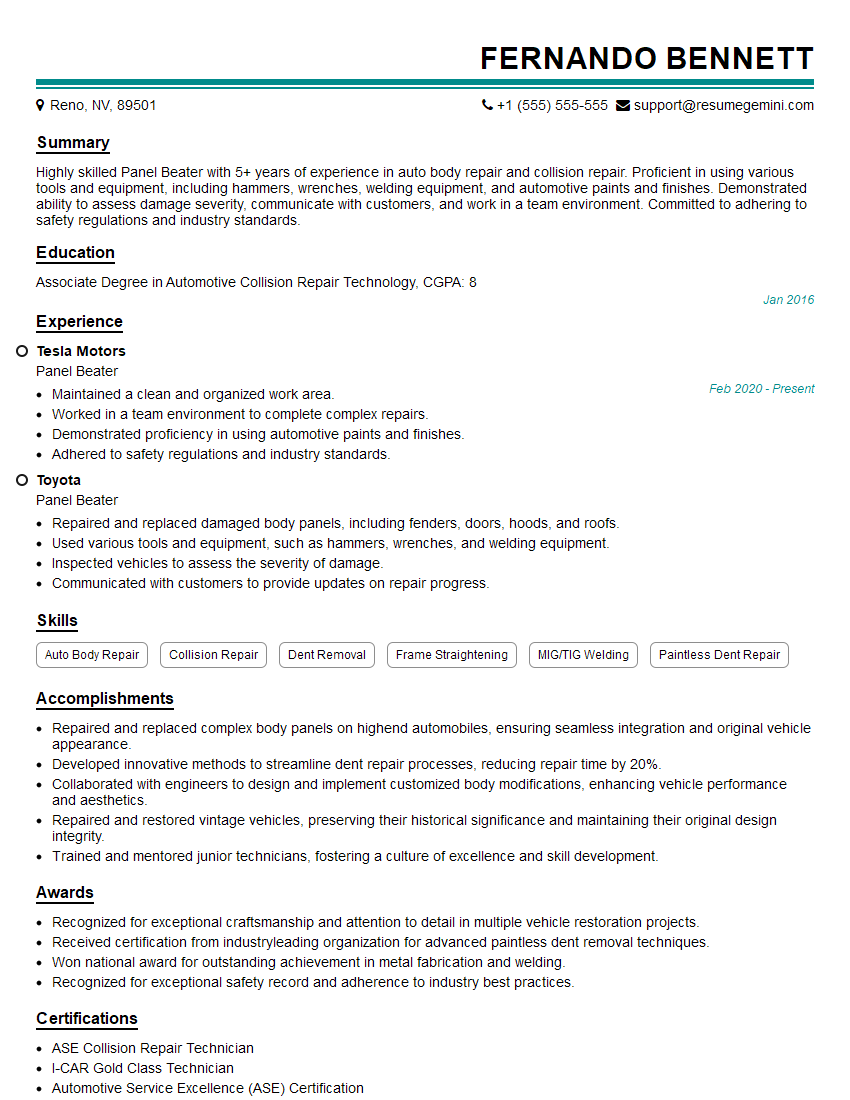

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Panel Beater

1. Explain the steps involved in repairing a minor dent on a car body panel?

- Clean the dented area and surrounding areas thoroughly.

- Use a stud welder to attach a slide hammer to the center of the dent.

- Gently pull the dent out using the slide hammer and a pulling tab.

- Use a rubber mallet or body hammer to gently tap the dent from the inside out.

- Sand and refinish the repaired area to match the surrounding paint.

2. What are the different types of welding techniques used in panel beating?

MIG welding

- Uses a continuously fed wire electrode.

- Produces a fast and strong weld.

- Suitable for repairing thin and thick sheet metal.

TIG welding

- Uses a non-consumable tungsten electrode.

- Produces a high-quality weld with minimal spatter.

- Suitable for welding thin and delicate metals.

Spot welding

- Uses two copper electrodes to create a localized weld.

- Produces a strong and durable joint.

- Suitable for joining overlapping metal sheets.

3. How do you ensure the accuracy of panel alignment during the repair process?

- Use a measuring tape or alignment gauge to check the distance and angles between key points on the panel.

- Compare the damaged panel to an undamaged one or use a repair manual for reference.

- Make small adjustments to the panel until it fits correctly.

- Use clamps or a frame to hold the panel in place while welding or bonding.

4. What are the common materials used in panel beating and how do you choose the right one?

- Steel: strong, durable, and easy to weld.

- Aluminum: lightweight, corrosion-resistant, but more difficult to weld.

- Composite materials: strong, lightweight, and corrosion-resistant, but more expensive and require specialized repair techniques.

Choosing the right material depends on:

- The location and severity of the damage.

- The original material of the panel.

- The budget and preferences of the customer.

5. How do you handle damaged areas that require replacement?

- Cut out the damaged area using a grinder or reciprocating saw.

- Form a new panel using a hammer and dolly or an English wheel.

- Weld or bond the new panel in place.

- Sand and refinish the repaired area to match the surrounding paint.

6. What safety precautions should be taken when working in a panel beating workshop?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Ensure proper ventilation to avoid inhaling harmful fumes.

- Handle welding equipment with care and follow all safety guidelines.

- Keep the work area clean and free of tripping hazards.

- Be aware of the location of fire extinguishers and know how to use them.

7. What are the challenges of repairing modern vehicles compared to older models?

- Increased use of advanced materials: Carbon fiber, aluminum, and composite materials require specialized repair techniques.

- Complex designs: Modern vehicles have more curves and intricate shapes, making it difficult to access damaged areas.

- Advanced electronics: Damage to sensors, wiring, and other electronic components can complicate the repair process.

- Safety features: Airbags, crumple zones, and other safety features can make it more difficult to repair vehicles without compromising safety.

8. Describe your experience with using specialized tools and equipment for panel beating.

- Hammer and dolly: Used to shape and smooth metal panels.

- Slide hammer: Used to pull out dents.

- Body filler: Used to fill in minor dents and scratches.

- MIG welder: Used to weld metal panels.

- TIG welder: Used to weld thin and delicate metals.

- English wheel: Used to form curved metal panels.

9. How do you stay up-to-date with the latest techniques and technologies in panel beating?

- Attend industry training courses and workshops.

- Read trade publications and online forums.

- Stay informed about new products and equipment.

- Network with other panel beaters and industry professionals.

10. What are your career goals and how do you see this position contributing to your professional development?

- Develop my skills as a panel beater and become a specialist in repairing modern vehicles.

- Contribute to the success of the team and the company.

- Gain experience in a fast-paced and challenging environment.

- Learn from experienced professionals and stay up-to-date with the latest industry trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Panel Beater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Panel Beater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Panel Beaters, also known as Autobody Repair Technicians, play a critical role in restoring damaged vehicles to their original condition. Their primary responsibilities revolve around repairing and replacing damaged body panels, ensuring the vehicle’s safety, functionality, and aesthetics.

1. Damage Assessment and Repair

Panel Beaters assess the extent of damage to vehicle body panels, frames, and other components. Based on their analysis, they determine the appropriate repair techniques, such as welding, grinding, or hammering, to restore the damaged parts to their original shape and integrity.

- Identify and assess damage to body panels, frames, bumpers, and other components

- Determine the most effective repair methods, considering the extent of damage, material type, and vehicle specifications

2. Panel Replacement and Installation

When damage is severe or beyond repair, Panel Beaters replace damaged panels with new or salvaged ones. They meticulously remove the damaged panels, prepare the surface for installation, and securely attach the new panels to the vehicle’s frame.

- Remove damaged panels, taking safety precautions to avoid further damage

- Prepare the surface for installation by cleaning, sanding, and applying primers

- Install new or salvaged panels, ensuring proper alignment and fit

3. Paint Matching and Blending

Panel Beaters match and blend the paint on repaired or replaced panels to ensure a seamless and aesthetically pleasing finish. They use specialized equipment and techniques to mix and apply paint, ensuring color and texture consistency.

- Identify and match the paint color and texture of the vehicle

- Prepare the painted surface for blending by sanding and masking

- Blend the new paint with the existing paint, creating a smooth and uniform finish

4. Quality Control and Inspection

Panel Beaters conduct rigorous quality control checks throughout the repair process to ensure the highest standards of workmanship. They inspect repaired panels, paint finishes, and overall vehicle alignment to identify any defects or areas requiring further attention.

- Inspect repaired panels for any imperfections, gaps, or misalignments

- Check paint finishes for color matching, smoothness, and durability

- Ensure the repaired vehicle meets safety and performance standards

Interview Tips

Preparing for a Panel Beater interview requires a comprehensive approach that encompasses technical knowledge, industry trends, and personal qualities. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Spend time researching the automotive repair industry, the specific company you are interviewing with, and their competitors. This demonstrates your interest and understanding of the field.

- Review the company’s website, social media pages, and industry news articles

- Identify the company’s unique strengths, specializations, and market position

- Understand the current challenges and trends in the autobody repair industry

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in panel beating, including welding, grinding, paint matching, and quality control. Quantify your accomplishments with specific examples and metrics.

- Describe how you repaired complex damage using advanced techniques

- Highlight your experience in matching and blending paint to achieve seamless finishes

- Provide examples of your commitment to quality and safety standards

3. Demonstrate Your Passion and Motivation

Convey your passion for autobody repair and your dedication to delivering exceptional results. Share your motivations for pursuing this career and how it aligns with your personal and professional goals.

- Explain why you find the process of repairing damaged vehicles rewarding

- Describe your attention to detail and commitment to precision

- Share any industry-related certifications or training you have pursued

4. Prepare for Common Interview Questions

Research common interview questions for Panel Beaters and prepare thoughtful answers that showcase your skills, experience, and personal qualities. Practice answering them concisely and confidently.

- Tell me about your experience with different types of vehicle damage

- Describe your approach to ensuring the quality and safety of your repairs

- How do you stay updated on the latest advancements in autobody repair techniques?

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewers and the company you are applying to.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Panel Beater, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Panel Beater positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.