Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Peanut Sheller interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Peanut Sheller so you can tailor your answers to impress potential employers.

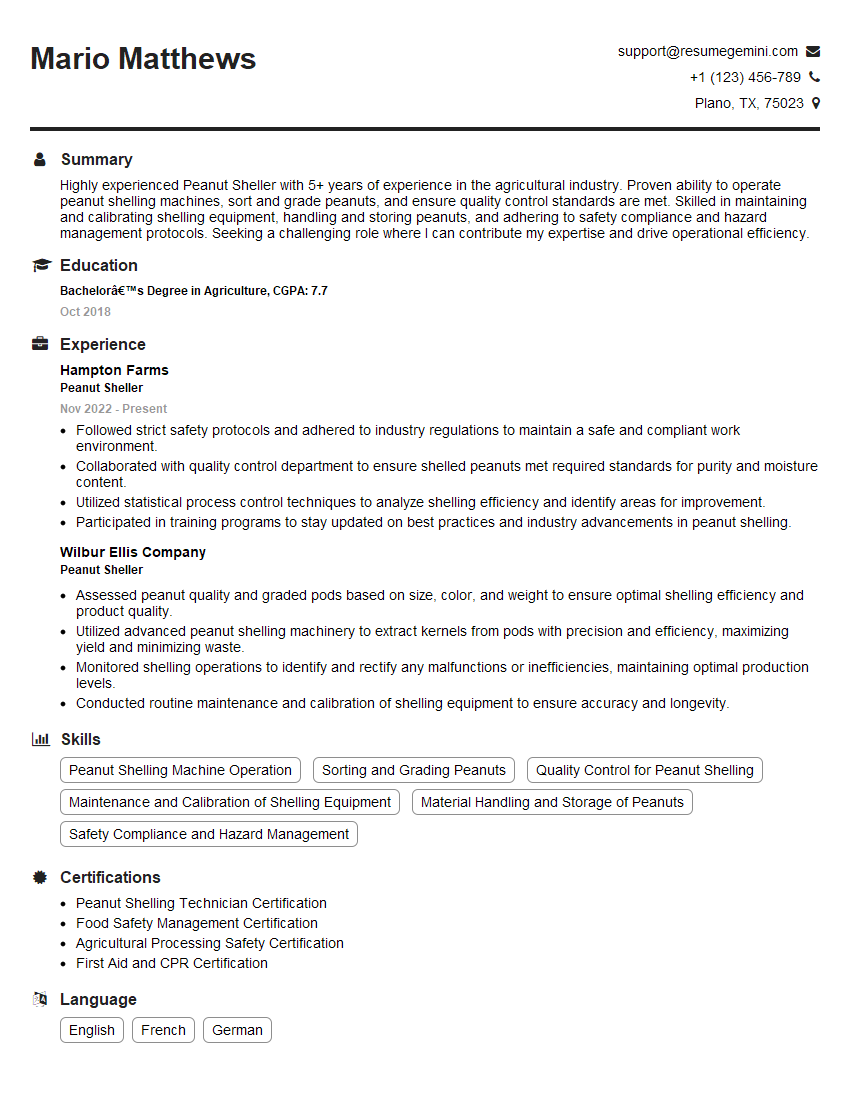

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Peanut Sheller

1. Describe the process of shelling peanuts using a peanut sheller machine.

- Involves feeding raw peanuts into the intake hopper.

- Peanuts pass through a series of rotating drums or cylinders.

- Drums have varying sizes and surface textures to crack and remove the peanut shells.

- A fan or air suction system separates the peanut kernels from the shells and debris.

- Kernels are collected in a separate container, while shells and other waste are disposed of.

2. Explain the different types of peanut shelling machines.

Static Sheller

- Stationary machine with fixed processing components.

- Suitable for small-scale operations.

Mobile Sheller

- Mounted on wheels for easy transportation.

- Ideal for farmers or contractors who need to process peanuts in different locations.

Continuous Sheller

- Processes peanuts in a continuous flow, with automated feeding and discharge systems.

- High efficiency and eignet for large-scale operations.

3. How do you determine the optimal settings for a peanut sheller machine?

- Assess the variety and quality of peanuts being processed.

- Calibrate the machine’s drum speed, clearance, and air flow to maximize shelling efficiency.

- Monitor the machine’s performance and make adjustments as necessary to achieve optimal kernel yield and minimize breakage.

4. What are the common maintenance and troubleshooting tasks for peanut shelling machines?

- Regular cleaning and inspection of machine components.

- Lubricate moving parts to ensure smooth operation.

- Check and replace worn or damaged parts promptly.

- Identify and resolve any electrical or mechanical issues that may affect the machine’s performance.

5. How do you ensure the quality and safety of shelled peanuts?

- Inspect peanuts before shelling for any defects or contamination.

- Use proper sanitation practices during the shelling process.

- Sort and grade peanut kernels based on size, quality, and moisture content.

- Store shelled peanuts in appropriate conditions to maintain their freshness and prevent spoilage.

6. What are the safety precautions to follow when operating a peanut sheller machine?

- Wear appropriate personal protective equipment (PPE).

- Never operate the machine without proper training.

- Keep the machine area clean and free from potential hazards.

- Follow manufacturer’s instructions for safe operation and maintenance.

7. Explain the importance of calibrating a peanut sheller machine.

- Ensures optimal shelling efficiency and minimizes kernel breakage.

- Prevents over-shelling or under-shelling, which can affect peanut quality.

- Optimizes the machine’s performance for different peanut varieties and conditions.

8. How do you handle situations where the peanut sheller machine produces a high percentage of broken kernels?

- Inspect the machine for any worn or damaged parts that may cause excessive breakage.

- Adjust the machine’s settings, such as drum speed or clearance, to minimize breakage.

- Assess the quality of peanuts being processed and make necessary adjustments to the shelling process.

9. What are the environmental considerations when using a peanut sheller machine?

- Minimize energy consumption by optimizing machine settings and using energy-efficient components.

- Properly dispose of peanut shells and other waste to prevent environmental pollution.

- Comply with local regulations regarding noise emissions and waste management.

10. How do you stay up-to-date with the latest advancements in peanut shelling technology?

- Attend industry conferences and trade shows.

- Read technical journals and articles on peanut processing.

- Consult with machinery manufacturers and experts.

- Participate in training programs or workshops.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Peanut Sheller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Peanut Sheller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operating Peanut Shelling Machines

Peanut Shellers are responsible for setting up, calibrating, and operating peanut shelling machines according to established procedures. They ensure that the machines are functioning properly and make adjustments as needed to optimize performance and minimize damage to peanuts.

2. Maintaining Peanut Shelling Machines

Regular maintenance of peanut shelling machines is crucial to ensure optimal performance and longevity. Peanut Shellers are responsible for performing routine maintenance tasks such as cleaning, lubricating, and replacing worn or damaged parts. They also conduct regular inspections to identify potential issues and take preventive measures to avoid breakdowns.

3. Monitoring Peanut Shelling Process

Peanut Shellers closely monitor the peanut shelling process to ensure that peanuts are being shelled effectively and efficiently. They observe the machines in operation, check the quality of shelled peanuts, and make adjustments to the settings or procedures as needed. By monitoring the process, they can identify and address any issues that may arise, such as blockages, uneven shelling, or damage to peanuts.

4. Ensuring Food Safety and Sanitation

Peanut Shellers play a vital role in maintaining food safety and sanitation standards in the peanut processing facility. They adhere to established hygiene practices, follow proper cleaning and disinfection procedures, and wear appropriate protective gear to prevent contamination. By maintaining a clean and sanitary work environment, they help ensure the safety and quality of the shelled peanuts.

Interview Preparation Tips

Preparing thoroughly for a peanut sheller interview can significantly increase your chances of success. Here are some key tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to research the peanut processing company and the specific role you are applying for. Familiarize yourself with the company’s mission, values, and products. Learn about the specific responsibilities and requirements of the peanut sheller position to demonstrate your understanding and interest in the job.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are directly relevant to the peanut sheller role. Focus on your ability to operate and maintain peanut shelling machines, your attention to detail, and your commitment to food safety and sanitation. Provide specific examples from your previous work experience to illustrate your capabilities.

3. Demonstrate Problem-Solving Abilities

Peanut shellers often encounter challenges and unexpected situations in their work. In the interview, be prepared to discuss your problem-solving abilities and how you have handled challenges in the past. Share examples of how you identified and resolved issues related to peanut shelling machines or the shelling process.

4. Show Enthusiasm and Motivation

Your enthusiasm for the peanut sheller role and the peanut industry can make a positive impression on the interviewer. Express your interest in the position and the company, and explain why you are motivated to work in this field. Show that you are eager to learn and contribute to the team’s success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Peanut Sheller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Peanut Sheller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.