Are you gearing up for a career in Perlite Grinder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Perlite Grinder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

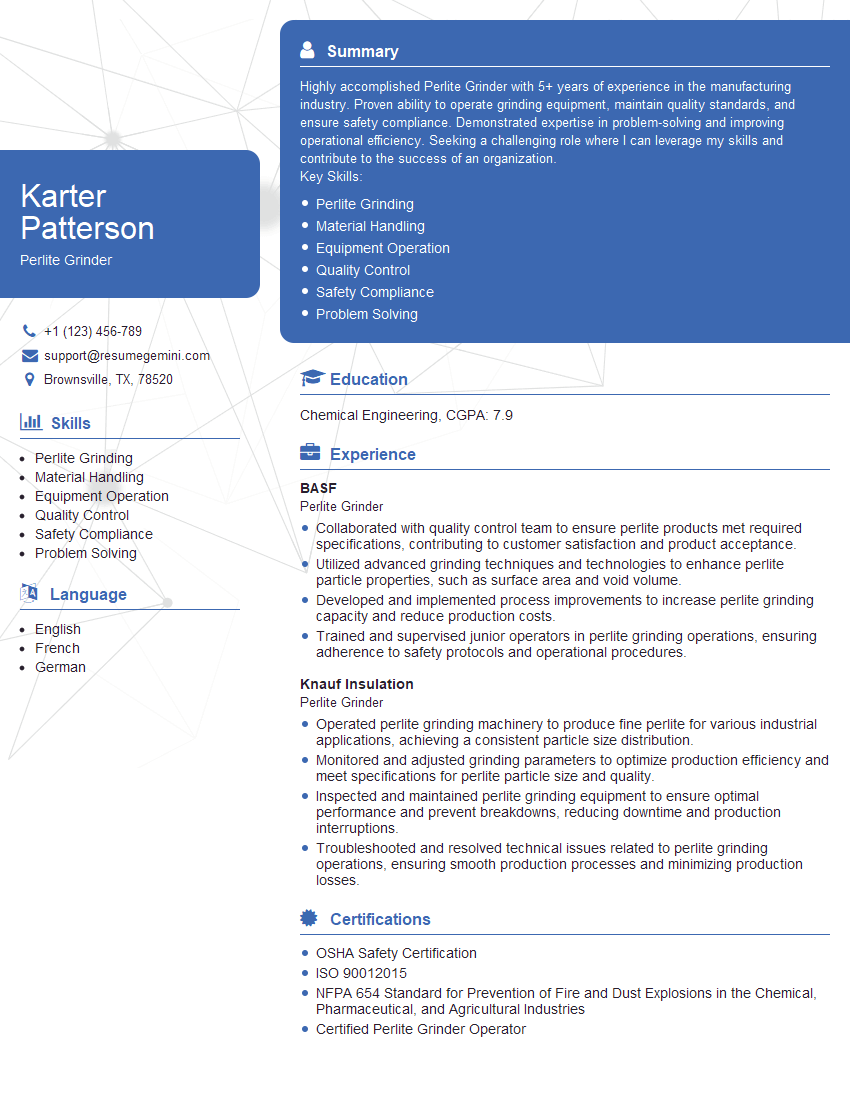

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Perlite Grinder

1. Describe the process of grinding perlite?

The process of grinding perlite involves the following steps:

- Selecting raw perlite ore

- Crushing the ore into smaller pieces

- Heating the crushed ore in a furnace to expand it

- Grinding the expanded perlite into a fine powder

- Classifying the ground perlite into different grades based on particle size

- Packaging the ground perlite for storage and shipping

2. What are the different types of perlite grinders?

There are two main types of perlite grinders:

- Horizontal grinders

- Vertical grinders

Horizontal grinders

- Consist of a horizontal grinding chamber with a rotating grinding wheel

- The perlite is fed into the chamber and the grinding wheel crushes it into a fine powder

Vertical grinders

- Consist of a vertical grinding chamber with a rotating grinding disc

- The perlite is fed into the chamber and the grinding disc crushes it into a fine powder

3. What are the factors that affect the quality of the ground perlite?

The quality of the ground perlite is affected by the following factors:

- The quality of the raw perlite ore

- The size of the grinding wheel or disc

- The speed of the grinding wheel or disc

- The temperature of the furnace

- The classification method

4. What are the safety precautions that must be taken when operating a perlite grinder?

When operating a perlite grinder, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as a dust mask, safety glasses, and gloves

- Ensure that the grinder is properly grounded and that the electrical cords are in good condition

- Keep the grinding area clean and free of debris

- Do not operate the grinder if it is damaged or malfunctioning

- Follow the manufacturer’s instructions for operation and maintenance

5. What are the maintenance procedures that must be performed on a perlite grinder?

Regular maintenance is required to keep a perlite grinder operating properly and safely. Some of the maintenance procedures that must be performed include:

- Inspecting the grinding wheel or disc for wear and tear

- Replacing the grinding wheel or disc when necessary

- Lubricating the bearings

- Cleaning the grinder regularly

- Calibrating the grinder

6. What are the troubleshooting steps that can be taken if a perlite grinder is not operating properly?

If a perlite grinder is not operating properly, the following troubleshooting steps can be taken:

- Check the power supply to ensure that the grinder is receiving electricity

- Check the grinding wheel or disc for wear and tear

- Inspect the bearings for lubrication

- Clean the grinder to remove any debris

- Calibrate the grinder

7. What are the different applications of ground perlite?

Ground perlite has a wide range of applications, including:

- As a lightweight aggregate in concrete and other building materials

- As a filter aid

- As a soil amendment

- As a packing material

- As a catalyst support

8. What are the advantages of using perlite as a grinding media?

Perlite has several advantages as a grinding media, including:

- Its low density, which reduces the energy required for grinding

- Its high porosity, which allows for better penetration of the grinding fluid

- Its chemical inertness, which prevents contamination of the ground product

- Its low cost

9. What are the disadvantages of using perlite as a grinding media?

Perlite also has some disadvantages as a grinding media, including:

- Its low hardness, which can lead to rapid wear of the grinding media

- Its friability, which can lead to the generation of fine dust

- Its low thermal conductivity, which can lead to overheating of the grinding media

10. What are the trends in the perlite grinding industry?

The perlite grinding industry is constantly evolving, with new technologies and applications being developed. Some of the current trends in the industry include:

- The development of new grinding technologies, such as high-energy milling and ultrasonic grinding

- The use of perlite in new applications, such as nanocomposites and lightweight ceramics

- The increasing demand for perlite grinding services from emerging markets

- The development of new environmental regulations that are driving the adoption of sustainable grinding practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Perlite Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Perlite Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Perlite Grinders play a pivotal role in the manufacturing process of expanded perlite, an essential material used in various industries. Their primary responsibilities encompass operating heavy machinery to crush and grind raw perlite into fine particles, ensuring optimal quality and consistency.

1. Crushing and Grinding Operations

Perlite Grinders are entrusted with the efficient operation of crushing and grinding equipment, which involves:

- Feeding raw perlite into crushing machines and monitoring the process to achieve the desired particle size.

- Calibrating and maintaining crushing and grinding machinery to ensure smooth and efficient operations.

2. Quality Control and Inspection

To guarantee the adherence to quality standards, Perlite Grinders conduct thorough inspections of finished products:

- Verifying the particle size and uniformity of the ground perlite using specialized testing equipment.

- Performing visual inspections to detect any impurities, discoloration, or other quality defects.

3. Equipment Maintenance and Troubleshooting

Perlite Grinders are responsible for maintaining the equipment they operate to ensure optimal performance:

- Conducting regular inspections, lubrication, and cleaning of crushing and grinding machinery.

- Troubleshooting operational issues, diagnosing faults, and implementing corrective actions to minimize downtime.

4. Production Planning and Optimization

To maximize productivity and efficiency, Perlite Grinders actively participate in:

- Collaborating with production teams to determine production schedules and monitor progress.

- Identifying areas for process improvement and implementing measures to enhance productivity and reduce costs.

Interview Tips

To excel in your Perlite Grinder interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry position, and the specific requirements of the Perlite Grinder role. This preparation demonstrates your interest and enthusiasm for the opportunity.

- Visit the company’s website, LinkedIn page, and industry news articles to gather relevant information.

- Carefully review the job description and identify key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your prior experience in operating heavy machinery and conducting quality control inspections. Showcase your knowledge of perlite processing techniques and equipment.

- Quantify your accomplishments using specific metrics to demonstrate your impact on previous roles.

- Provide examples of successful problem-solving and troubleshooting experiences.

3. Showcase Your Commitment to Safety

Perlite grinding operations involve working with heavy machinery and hazardous materials. Emphasize your adherence to safety regulations and your commitment to maintaining a safe work environment.

- Describe your experience with safety protocols and equipment.

- Highlight your understanding of the potential hazards associated with perlite grinding and your strategies for mitigating risks.

4. Prepare for Technical Questions

Expect technical questions related to perlite grinding equipment, quality control procedures, and troubleshooting techniques. Prepare by reviewing industry-specific literature and practicing answering questions related to your technical expertise.

- Familiarize yourself with different types of crushing and grinding machinery.

- Study the principles of particle size analysis and quality control techniques.

Next Step:

Now that you’re armed with the knowledge of Perlite Grinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Perlite Grinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini