Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pigment Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pigment Grinder so you can tailor your answers to impress potential employers.

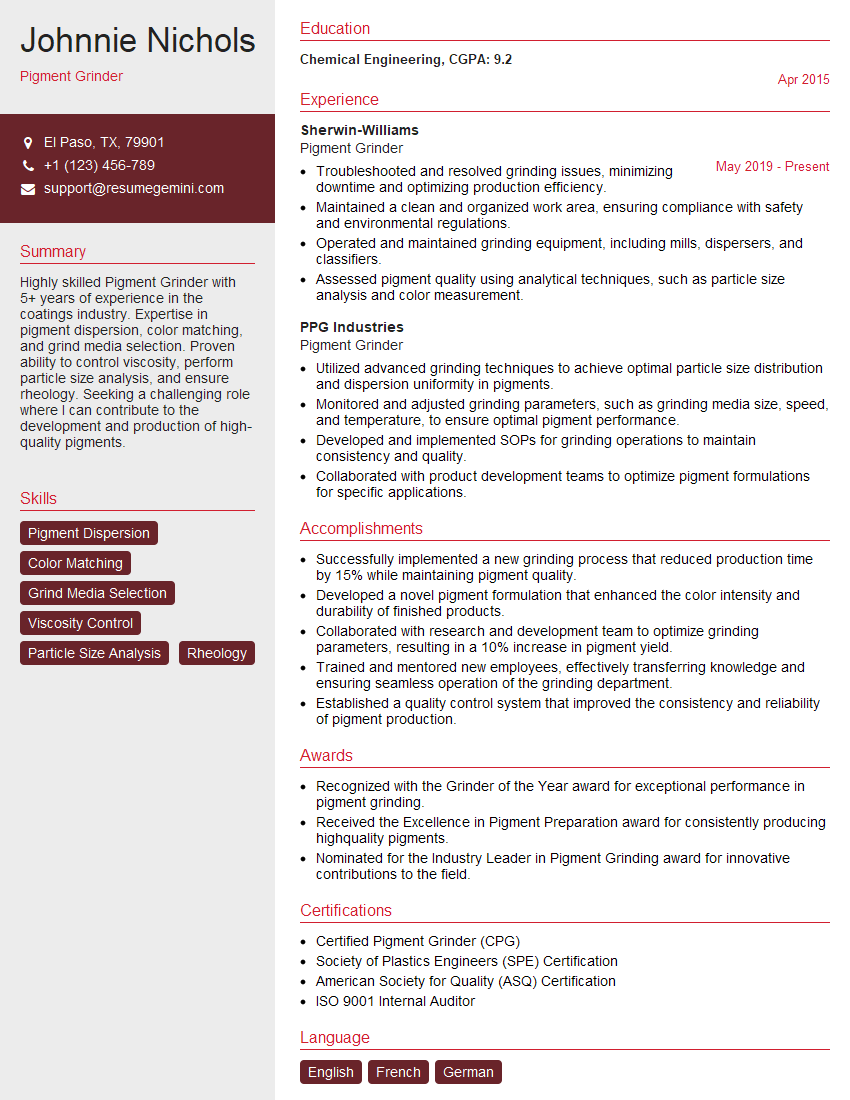

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pigment Grinder

1. Describe the key responsibilities of a Pigment Grinder?

As a Pigment Grinder, my main responsibilities include:

- Operate grinding machines to reduce pigments to the desired particle size and consistency.

- Monitor the grinding process to ensure the production of high-quality pigments.

- Maintain and calibrate grinding equipment to optimize performance and minimize downtime.

- Follow established safety protocols and wear appropriate personal protective equipment (PPE) while working with potentially hazardous materials.

2. How do you ensure the quality of the ground pigments?

Process Control:

- Adhere to standardized grinding procedures and closely monitor process parameters.

Testing and Inspection:

- Conduct regular quality control checks using particle size analyzers and other testing methods.

- Inspect the ground pigments visually to ensure they meet the desired color, consistency, and absence of impurities.

Continuous Improvement:

- Analyze quality data and implement improvements to optimize the grinding process further.

3. What are the different types of grinding mills used for pigment grinding?

Ball Mill:

- Uses rotating balls to grind pigments in a cylindrical chamber.

- Suitable for large-scale production and coarse grinding.

Attritor Mill:

- Employs high-speed impellers to generate friction and shear forces for grinding.

- Used for fine grinding and achieving uniform particle size distribution.

Bead Mill:

- Utilizes glass or ceramic beads as the grinding media.

- Capable of producing very fine pigments with narrow particle size distribution.

4. How do you handle and store different types of pigments safely?

Hazard Identification:

- Review the Material Safety Data Sheets (MSDSs) for each pigment.

Safe Handling:

- Use proper PPE, including gloves, masks, and safety glasses.

- Handle pigments in well-ventilated areas to minimize dust exposure.

Storage Conditions:

- Store pigments in dry, cool, and well-sealed containers.

- Consider the compatibility of different pigments and separate them as necessary.

5. What is the importance of particle size distribution in pigment grinding?

Particle size distribution significantly affects the performance of pigments in various applications, such as:

- Color Strength: Smaller particles provide more surface area for light absorption, resulting in higher color intensity.

- Opacity and Hiding Power: Uniform particle size distribution enhances the opacity and hiding power of pigments.

- Dispersion and Stability: Optimal particle size distribution promotes better dispersion and stability in paints and coatings.

- Rheological Properties: The particle size distribution influences the viscosity and flow properties of pigment dispersions.

6. What are the common challenges faced in pigment grinding, and how do you overcome them?

Contamination:

- Follow strict cleaning procedures and use dedicated equipment for different pigments.

Overgrinding:

- Monitor grinding time and particle size closely to prevent excessive grinding.

Equipment Maintenance:

- Perform regular maintenance and calibration of grinding mills to ensure optimal performance.

7. What is your understanding of the role of dispersants in pigment grinding?

Dispersants are chemical additives used to prevent pigment agglomeration and promote dispersion in various media, such as paints and inks.

- They work by reducing surface tension and electrostatic forces between pigment particles.

- Selecting the appropriate dispersant depends on the specific pigment and application requirements.

8. How do you optimize the grinding process for different pigments?

Grinding Media Selection:

- Choose grinding media (e.g., balls, beads) based on the hardness and particle size requirements of the pigment.

Grinding Parameters:

- Adjust grinding speed, time, and temperature to optimize particle size distribution and minimize overgrinding.

Additives and Dispersants:

- Use additives and dispersants as needed to enhance grinding efficiency and prevent agglomeration.

9. How do you ensure consistency in the quality of ground pigments over time?

Standardized Procedures:

- Establish and follow standardized grinding procedures and quality control measures.

Equipment Calibration:

- Regularly calibrate grinding equipment to maintain accuracy and precision.

Record Keeping:

- Maintain detailed records of grinding parameters, quality control data, and any deviations from standard procedures.

10. What are your career aspirations in the field of pigment grinding?

In the long term, I aspire to advance my role within the pigment grinding industry.

- I am particularly interested in exploring the development and implementation of innovative grinding techniques to improve efficiency and quality.

- Moreover, I aim to contribute to the industry’s sustainability efforts by optimizing processes and minimizing waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pigment Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pigment Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pigment Grinder plays a key role in the manufacturing process of colored materials, such as paints, plastics, and inks. The key responsibilities of a Pigment Grinder include:

1. Pigment Grinding

Grind and disperse pigments into liquids, such as water, oil, or resin, to create a smooth and consistent paste.

- Operate grinding machines to combine and mix pigments with liquids and additives.

- Monitor equipment to ensure proper mixing and dispersion of pigments.

2. Quality Control

Ensure the quality of the ground pigments meets the desired specifications.

- Perform quality control checks to assess color consistency, particle size, and viscosity.

- Make adjustments to the grinding process or materials as needed to maintain quality standards.

3. Equipment Maintenance

Perform basic maintenance and cleaning of grinding equipment.

- Clean and lubricate grinding machines.

- Inspect equipment for wear and tear, and report any issues to supervisors.

4. Safety and Compliance

Adhere to safety regulations and industry standards.

- Wear appropriate safety gear, such as respirators and protective clothing.

- Follow established safety procedures for handling and disposing of chemicals.

Interview Tips

To prepare for the interview and ace it, follow these tips:

1. Research the Company and Industry

Learn about the company’s history, values, and current projects. Understand the industry trends and competitive landscape.

- Visit the company website, read industry publications, and talk to people in the field.

- This shows your interest and enthusiasm for the role and industry.

2. Practice Common Interview Questions

Expect questions about your experience, skills, and knowledge of the pigment grinding process. Prepare thoughtful answers that highlight your strengths.

- Write out potential answers and practice speaking them out loud.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Emphasize Your Technical Skills

The interviewer wants to know your expertise in pigment grinding. Showcase your understanding of equipment, processes, and quality control procedures.

- Highlight your experience with different types of grinding machines and techniques.

- Provide examples of how you have improved efficiency or accuracy in your previous roles.

4. Demonstrate Passion and Attention to Detail

Pigment grinding requires precision and dedication. Explain why you enjoy this work and how you consistently meet or exceed expectations.

- Share specific examples of how you pay attention to detail and take pride in your work.

- Discuss your eagerness to learn new techniques and stay updated on industry best practices.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pigment Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pigment Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.