Are you gearing up for a career in Planer Type Milling Machine Set-Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Planer Type Milling Machine Set-Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

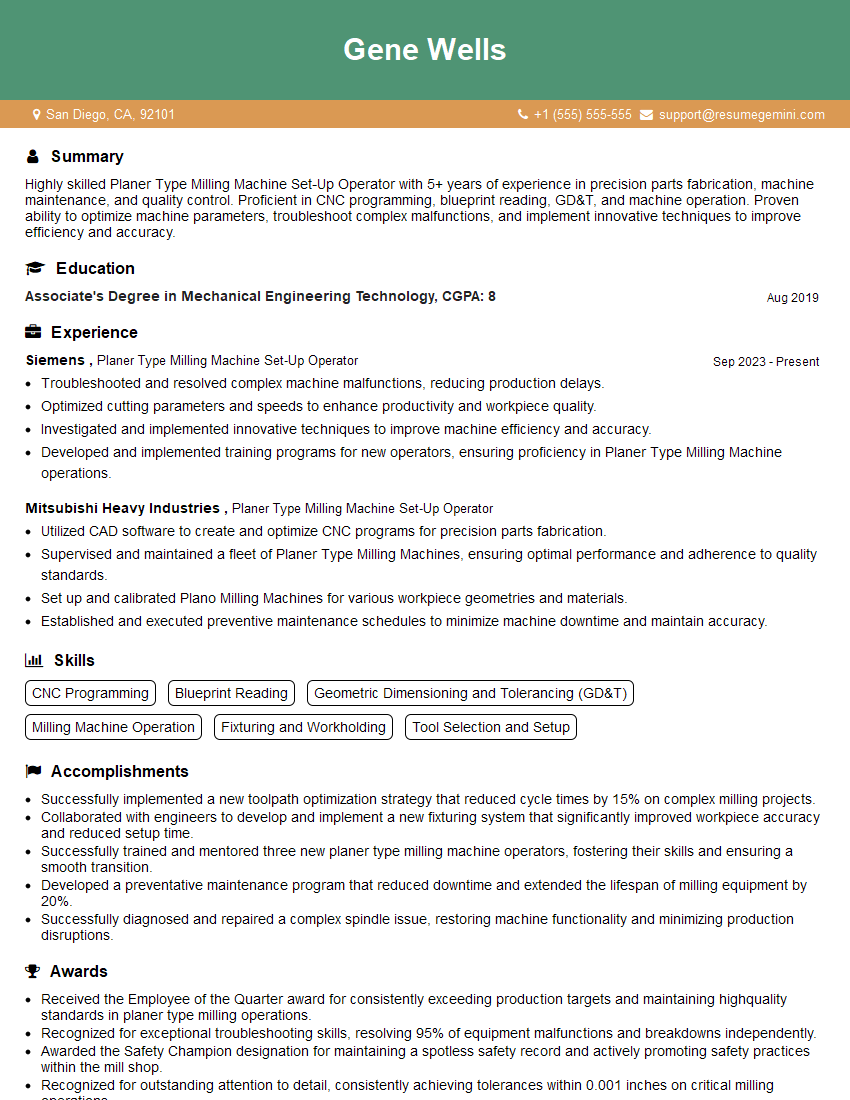

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planer Type Milling Machine Set-Up Operator

1. Describe the process of setting up a planer type milling machine?

The setup process for a planer type milling machine is as follows:

- Mount the workpiece: Secure the workpiece to the machine table using clamps or a vise.

- Select and install the milling cutter: Choose the appropriate cutter for the desired operation and mount it to the machine spindle.

- Set the cutting parameters: Determine and set the feed rate, spindle speed, and cutting depth based on the material and cutter specifications.

- Align the workpiece: Use the machine controls to align the workpiece and cutter to achieve the desired cutting position.

- Start the machine and monitor the operation: Start the milling process and monitor its progress, making adjustments as needed to ensure a smooth and efficient cut.

2. How do you calculate the feed rate for a planer type milling machine?

The feed rate for a planer type milling machine is calculated using the following formula:

- Feed rate (in/min) = Spindle speed (rpm) x Number of teeth on cutter x Feed per tooth (in)

It is important to consider the material’s machinability and the cutter’s geometry when selecting the appropriate feed rate to ensure optimal cutting performance.

3. What types of materials can be machined on a planer type milling machine?

Planer type milling machines can machine a wide range of materials, including:

- Metals (e.g., steel, aluminum, brass, titanium)

- Plastics

- Wood

- Composites

The choice of cutter and cutting parameters must be appropriate for the specific material to achieve the desired results.

4. What are the different types of milling operations that can be performed on a planer type milling machine?

Planer type milling machines are capable of performing various milling operations, such as:

- Face milling: Creating a flat surface on the workpiece

- Peripheral milling: Cutting a profile or shape into the workpiece using the side of the cutter

- Slotting: Creating a narrow, elongated groove in the workpiece

- Form milling: Cutting a complex shape into the workpiece using a form cutter

5. What are the safety precautions to be followed when operating a planer type milling machine?

When operating a planer type milling machine, it is crucial to follow these safety precautions:

- Wear appropriate safety gear: Including eye protection, earplugs, and gloves

- Securely mount the workpiece and cutting tools: To prevent accidents caused by loose or moving components

- Keep the work area clean and organized: To avoid tripping hazards or contact with sharp objects

- Never operate the machine if it is malfunctioning or damaged: To prevent potential injuries

- Be aware of the machine’s moving parts: To avoid getting caught or injured

6. How do you maintain a planer type milling machine?

Regular maintenance is essential to ensure the optimal performance and longevity of a planer type milling machine:

- Clean the machine regularly: Remove chips, debris, and coolant to prevent buildup

- Lubricate moving parts: According to the manufacturer’s recommendations

- Inspect and replace worn or damaged components: Such as cutters, bearings, and belts

- Calibrate the machine periodically: To ensure accurate positioning and cutting

7. What troubleshooting steps would you take if the planer type milling machine is producing poor-quality cuts?

If the planer type milling machine is producing poor-quality cuts, the following troubleshooting steps can be taken:

- Check the cutting tool: Ensure it is sharp and undamaged

- Verify the cutting parameters: Adjust the feed rate, spindle speed, and cutting depth as needed

- Inspect the workpiece: Ensure it is securely mounted and free from defects

- Check the machine’s alignment: Verify that the workpiece and cutter are aligned correctly

- Examine the coolant system: Ensure it is functioning properly to provide adequate cooling and lubrication

8. How do you ensure the accuracy of the parts produced on a planer type milling machine?

To ensure the accuracy of parts produced on a planer type milling machine, the following steps are important:

- Use high-quality cutting tools: Precision-ground cutters with sharp edges

- Properly calibrate the machine: According to the manufacturer’s specifications

- Follow the recommended cutting parameters: Based on the material and cutter being used

- Use precision measuring tools: To verify the dimensions and tolerances of the finished parts

- Implement quality control measures: To monitor the accuracy and consistency of the production process

9. How do you handle complex milling jobs that require multiple setups on a planer type milling machine?

When handling complex milling jobs that require multiple setups on a planer type milling machine:

- Plan the setups carefully: Determine the sequence of operations and necessary setups

- Use jigs and fixtures: To ensure accurate positioning and repeatability across setups

- Coordinate with other team members: To avoid errors and ensure a smooth workflow

- Document the setup parameters: To facilitate future setups and maintain consistency

- Monitor the process closely: To identify and address any potential issues

10. Describe your experience in using advanced CAM software for programming and simulating planer type milling operations?

I have experience using advanced CAM software to program and simulate planer type milling operations. This software enables me to:

- Create 3D models of parts: For accurate simulation and toolpath generation

- Define complex toolpaths: With precise control over feed rates, spindle speeds, and cutting depths

- Simulate the milling process: To verify tool movements, identify potential collisions, and optimize cutting parameters

- Generate NC code: For efficient execution of the milling program on the machine

- Troubleshoot errors: By analyzing simulation results and identifying areas for improvement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planer Type Milling Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planer Type Milling Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Planer Type Milling Machine Set-Up Operator is responsible for setting up, operating, and maintaining a planer type milling machine. This involves:

1. Machine Setup

Installing and securing workpieces and fixtures

- Selecting and installing appropriate cutting tools

- Establishing and aligning machine settings

2. Machine Operation

Operating the machine to perform milling operations

- Monitoring machine performance and adjusting settings as needed

- Ensuring that workpieces are milled to specifications

3. Machine Maintenance

Performing routine maintenance and repairs on the machine

- Cleaning and lubricating machine components

- Inspecting and replacing worn or damaged parts

4. Quality Control

Inspecting workpieces to ensure they meet quality standards

- Using measuring tools and gauges

- Reporting any defects or discrepancies

Interview Tips

To prepare for an interview for a Planer Type Milling Machine Set-Up Operator position, you should:

1. Research the company and the position

This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website and social media pages

- Read industry news and articles

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview.

- Prepare a list of your skills and experience

- Think about examples of times when you have demonstrated the skills required for the position

3. Dress professionally

This will show the interviewer that you are serious about the position and that you are taking the interview seriously.

- Dress in business casual attire

- Make sure your clothes are clean and pressed

4. Be on time

This will show the interviewer that you are respectful of their time and that you are organized.

- Plan your route to the interview in advance

- Allow yourself plenty of time to get to the interview

5. Be confident

This will help you make a positive impression on the interviewer.

- Believe in yourself and your abilities

- Speak clearly and confidently

Next Step:

Now that you’re armed with the knowledge of Planer Type Milling Machine Set-Up Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Planer Type Milling Machine Set-Up Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini