Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plant and Equipment Worker (P&E Worker) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plant and Equipment Worker (P&E Worker) so you can tailor your answers to impress potential employers.

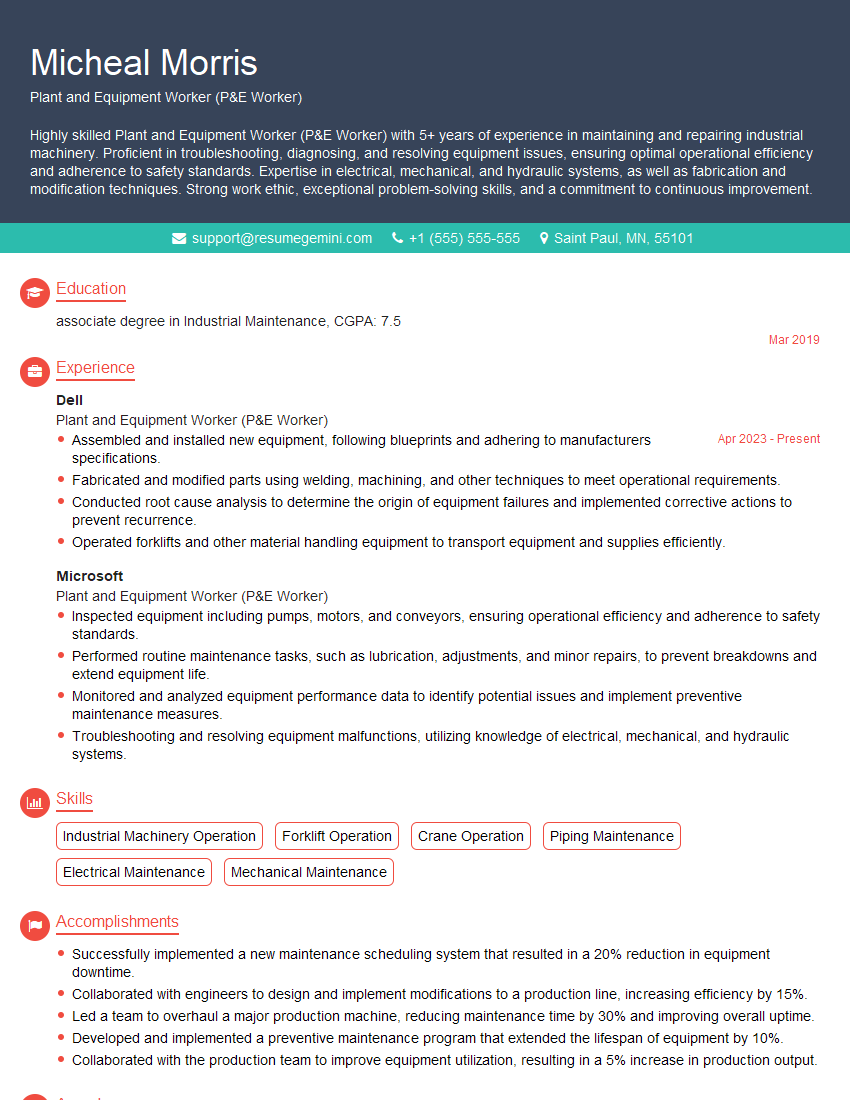

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plant and Equipment Worker (P&E Worker)

1. Walk me through the process of performing a basic inspection of a piece of equipment?

- Visually inspect the equipment for any signs of damage or wear.

- Check for proper lubrication and coolant levels.

- Listen for any unusual noises or vibrations.

- Review the equipment’s maintenance log for any recent issues.

- Test the equipment’s functionality by operating it under load.

2. How do you troubleshoot common problems encountered in industrial equipment?

Diagnostics

- Identify the symptoms of the problem.

- Gather information about the equipment’s history and operating conditions.

- Review technical documentation and maintenance logs.

Resolution

- Inspect components for damage or wear.

- Verify electrical connections and wirings.

- Calibrate sensors and actuators.

- Replace or repair defective parts.

3. Describe the different types of lubricants used in industrial equipment and their specific applications?

- Oils: Lubricate moving parts, reduce friction, and protect against wear. Used in engines, bearings, and gears.

- Greases: Thicker than oils, provide long-term lubrication and protect against extreme temperatures and moisture. Used in bearings, seals, and gears.

- Synthetic Lubricants: Engineered for specific applications, offer superior performance and longer life compared to conventional lubricants.

4. Discuss the importance of proper equipment grounding and how to ensure it is done correctly?

- Prevents electrical shocks and fires by providing a safe path for electrical current to flow to the ground.

- Connect equipment to a low-impedance ground using a proper grounding conductor.

- Ensure all electrical connections are tight and secure.

- Periodically test grounding systems to verify their integrity.

5. Explain the safety precautions you should take when working on or near heavy machinery?

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

- Lock out and tag out equipment before performing any maintenance or repairs.

- Use proper lifting techniques when moving heavy objects.

- Be aware of your surroundings and potential hazards.

- Never work alone and follow established safety protocols.

6. What is your experience with using hydraulic and pneumatic systems in industrial equipment?

- Hydraulics: Knowledge of hydraulic fluid properties, cylinder operation, and troubleshooting hydraulic leaks and pressure issues.

- Pneumatics: Understanding of compressed air systems, valve operation, and troubleshooting pneumatic leaks and pressure problems.

7. Describe your experience with preventative maintenance programs. How do you develop and implement them?

- Assess equipment condition, identify potential failures, and establish maintenance schedules.

- Create work orders, assign tasks, and track maintenance activities.

- Analyze maintenance data to identify trends and improve program effectiveness.

8. How do you stay updated on the latest technical advancements and industry best practices in plant and equipment maintenance?

- Attend industry conferences and seminars.

- Read technical publications and journals.

- Participate in online forums and discussion groups.

- Seek training opportunities from equipment manufacturers.

9. What is your approach to collaborating with other team members, such as engineers and maintenance technicians?

- Communicate clearly and effectively to share information and coordinate tasks.

- Respect the expertise of others and actively seek their input.

- Work together to solve problems and improve equipment reliability.

10. Why are you interested in working as a Plant and Equipment Worker for our company specifically?

- Company’s reputation for excellence in manufacturing and maintenance.

- Opportunity to contribute to the company’s success and growth.

- Commitment to safety and employee development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plant and Equipment Worker (P&E Worker).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plant and Equipment Worker (P&E Worker)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plant and Equipment Workers are responsible for the proper operation and maintenance of machinery and equipment in industrial settings. Key responsibilities include:

1. Equipment Operation and Troubleshooting

Operating and monitoring various equipment, ensuring optimal performance and efficiency.

- Identifying and resolving equipment malfunctions and breakdowns.

- Performing scheduled maintenance and repairs to prevent costly downtime.

2. Quality Control and Inspection

Ensuring manufactured products meet quality standards.

- Inspecting materials and products, identifying defects and reporting discrepancies.

- Maintaining accurate records of inspection results and adherence to quality protocols.

3. Safety and Compliance

Ensuring a safe work environment and compliance with regulations.

- Operating equipment safely and adhering to established safety protocols.

- Maintaining a clean and organized work area to prevent accidents.

4. Communication and Collaboration

Working effectively with colleagues and supervisors.

- Communicating equipment status, maintenance needs, and work progress to supervisors.

- Collaborating with team members to resolve complex issues and improve efficiency.

Interview Preparation Tips

To help candidates ace the Plant and Equipment Worker interview, consider these preparation tips:

1. Research the Role and Company

Thoroughly review the job description and company information. Understanding the specific requirements and company culture will provide context for your answers.

2. Highlight Technical Skills and Experience

Emphasize your proficiency in operating and maintaining machinery. Provide specific examples of equipment you have worked with and any relevant certifications or training.

3. Showcase Safety Awareness

Demonstrate your knowledge of safety regulations and commitment to a safe work environment. Describe experiences where you implemented safety protocols or identified potential hazards.

4. Prepare for Behavioral Questions

Be ready to discuss your teamwork, problem-solving, and communication skills. Use the STAR method (Situation, Task, Action, Result) to answer questions about specific work experiences.

5. Ask Informed Questions

Ask thoughtful questions about the company, the role, or industry trends. This shows your interest and engagement in the opportunity.

6. Dress Professionally and Arrive on Time

Demonstrate your professionalism by dressing appropriately and punctuality. This creates a positive first impression and shows respect for the interviewers.

7. Practice Your Answers

Rehearse your answers to common interview questions. This will build your confidence and reduce nervousness during the actual interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plant and Equipment Worker (P&E Worker) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!