Are you gearing up for a career in Plexiglas Former? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plexiglas Former and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

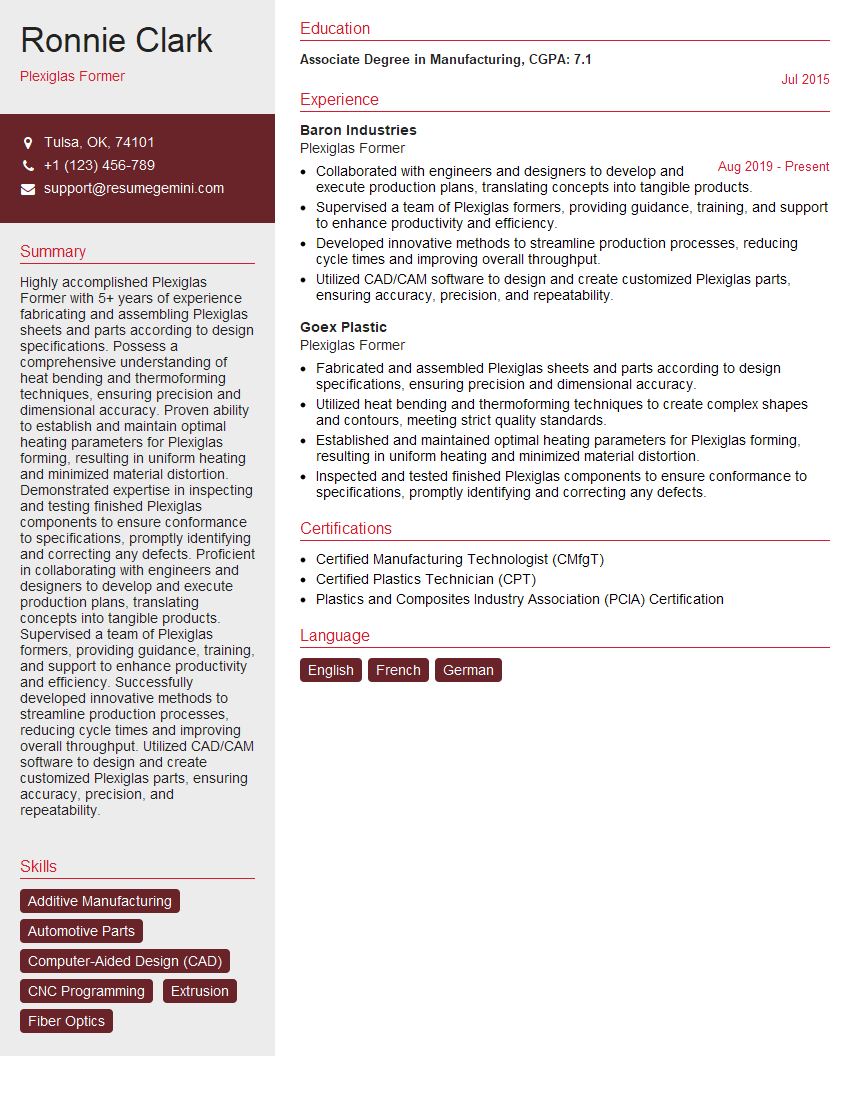

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plexiglas Former

1. What are the different types of Plexiglas available?

There are various forms of Plexiglas, each with unique qualities and uses. Some of the most common types include:

- Extruded Plexiglas: Created by forcing molten Plexiglas through a die, resulting in a continuous sheet with consistent thickness and superior impact resistance.

- Cast Plexiglas: Produced by pouring liquid Plexiglas into a mold, offering excellent optical clarity and dimensional stability.

- Cellular Plexiglas: Featuring a honeycomb-like structure, cellular Plexiglas is lightweight, durable, and provides thermal insulation.

2. How do you determine the appropriate thickness for a Plexiglas project?

Factors to Consider

- Purpose and Application: Thicker Plexiglas is required for load-bearing applications or to withstand impacts.

- Size and Shape: Larger or irregularly shaped pieces require thicker Plexiglas to prevent bending or distortion.

- Environmental Conditions: Plexiglas exposed to extreme temperatures or UV radiation may need increased thickness for durability.

Calculation Considerations

- Span Table: Industry-specific tables provide recommendations based on the span distance between supports.

- Deflection Formula: Calculate the maximum deflection (sag) to ensure it meets project requirements.

3. What are the key considerations for forming Plexiglas?

- Heating Temperature: Plexiglas must reach a specific temperature to become pliable and formable.

- Forming Technique: Vacuum forming, press forming, or drape forming are common methods to shape Plexiglas.

- Mold Design: The mold’s shape, surface finish, and cooling system impact the accuracy and quality of the formed Plexiglas.

- Cooling Process: Controlled cooling ensures the Plexiglas retains its desired shape and prevents stress cracking.

4. How do you ensure the durability of Plexiglas in outdoor applications?

- UV Protection: Choose UV-resistant Plexiglas or apply a UV-resistant coating to protect against sun damage and yellowing.

- Scratch Resistance: Use scratch-resistant coatings or incorporate additives during manufacturing to enhance surface durability.

- Weather Resistance: Select Plexiglas grades designed to withstand extreme temperatures, rain, snow, and wind.

- Proper Installation: Ensure correct fastening methods and expansion joints to accommodate thermal expansion and contraction.

5. What safety precautions should be observed when working with Plexiglas?

- Wear Protective Gear: Use gloves, safety glasses, and a respirator to prevent exposure to dust and fumes.

- Adequate Ventilation: Ensure proper ventilation to prevent inhalation of harmful vapors.

- Avoid Contact with Heat: Keep Plexiglas away from naked flames or excessive heat sources to prevent melting or combustion.

- Handle with Care: Plexiglas is susceptible to scratches and breakage, so handle it carefully during transportation and installation.

6. How do you troubleshoot common problems encountered during Plexiglas fabrication?

- Bubbles or Voids: Ensure proper vacuum pressure, mold cleanliness, and adequate heating during forming.

- Distortion: Check heating temperature, mold accuracy, and cooling process for irregularities.

- Cracking: Identify sources of stress, such as improper mold design, rapid cooling, or excessive handling.

- Yellowing: Use UV-resistant Plexiglas or apply UV-resistant coatings to prevent sun damage.

7. What are the latest advancements in Plexiglas technology?

- Anti-Fog Coatings: Innovative coatings prevent fogging in humid environments for improved visibility.

- Self-Cleaning Properties: Advanced materials incorporate self-cleaning properties to repel dirt and water.

- Noise Reduction: Plexiglas panels with sound-absorbing qualities are used in acoustic applications.

- Lightweight and Durable Composites: Combinations of Plexiglas and other materials provide exceptional strength-to-weight ratios.

8. How do you stay updated on the latest best practices and industry trends in Plexiglas fabrication?

- Attend Industry Conferences: Participate in events to learn from experts and network with professionals.

- Subscribe to Trade Publications: Stay informed through industry-specific magazines and journals.

- Research Online: Utilize reputable websites, webinars, and online forums to access up-to-date information.

- Connect with Suppliers: Engage with Plexiglas suppliers to gain insights into new products and technologies.

9. What sets you apart from other Plexiglas Formers in the industry?

- Experience and Expertise: Highlight your years of experience and expertise in Plexiglas forming.

- Proven Track Record: Showcase successful projects that demonstrate your skills and abilities.

- Knowledge of Industry Standards: Emphasize your understanding and adherence to industry best practices.

- Commitment to Quality: Express your dedication to delivering high-quality Plexiglas products that meet customer specifications.

10. How do you handle complex and challenging Plexiglas forming projects?

- Collaboration: Engage with designers, engineers, and clients to understand project requirements and develop innovative solutions.

- Prototyping: Create prototypes to test designs and identify potential issues before full-scale production.

- Advanced Techniques: Utilize advanced forming techniques, such as multi-axis bending, to achieve complex shapes and geometries.

- Quality Control: Implement rigorous quality control measures throughout the fabrication process to ensure accuracy and precision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plexiglas Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plexiglas Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plexiglas Formers are responsible for shaping and forming plexiglass into custom shapes and designs. They use a variety of tools and techniques to create products such as display cases, trophies, and furniture.

1. Shaping and forming plexiglass

Plexiglas Formers use a variety of tools and techniques to shape and form plexiglass. These tools include ovens, heat guns, and vacuum forming machines. Plexiglas Formers must have a good understanding of the properties of plexiglass and how to work with it safely.

- Use ovens to heat plexiglass to a pliable state

- Use heat guns to shape and mold plexiglass

- Use vacuum forming machines to create complex shapes

2. Creating custom designs

Plexiglas Formers often work with customers to create custom designs. They must be able to understand the customer’s needs and translate them into a workable design. Plexiglas Formers must also be able to work independently and use their creativity to solve problems.

- Work with customers to understand their needs

- Translate customer needs into workable designs

- Use creativity to solve problems

3. Finishing and assembling products

Once the plexiglass has been shaped and formed, Plexiglas Formers must finish and assemble the products. This may involve sanding, polishing, and gluing the pieces together. Plexiglas Formers must be able to produce high-quality products that meet the customer’s specifications.

- Sand and polish plexiglass

- Glue pieces together

- Produce high-quality products

4. Maintaining equipment

Plexiglas Formers must also maintain the equipment they use. This includes cleaning and lubricating the machines and making sure they are in good working order. Plexiglas Formers must be able to troubleshoot problems and make repairs as needed.

- Clean and lubricate machines

- Make sure machines are in good working order

- Troubleshoot problems

- Make repairs

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. You can find this information on the company’s website, social media pages, and Glassdoor.

- Visit the company’s website

- Check out the company’s social media pages

- Read reviews on Glassdoor

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Deliver your answers confidently and concisely

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills. Be prepared to talk about your relevant work experience, education, and any skills that you have that would be beneficial to the position. You can also prepare examples of your work to show the interviewer.

- Talk about your relevant work experience

- Discuss your education

- Highlight your skills

- Prepare examples of your work

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

5. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Show the interviewer that you are passionate about the position and that you would be a valuable asset to the company.

- Be yourself

- Be enthusiastic

- Show the interviewer that you are passionate about the position

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plexiglas Former role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.