Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Powder Cutting Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Powder Cutting Operator so you can tailor your answers to impress potential employers.

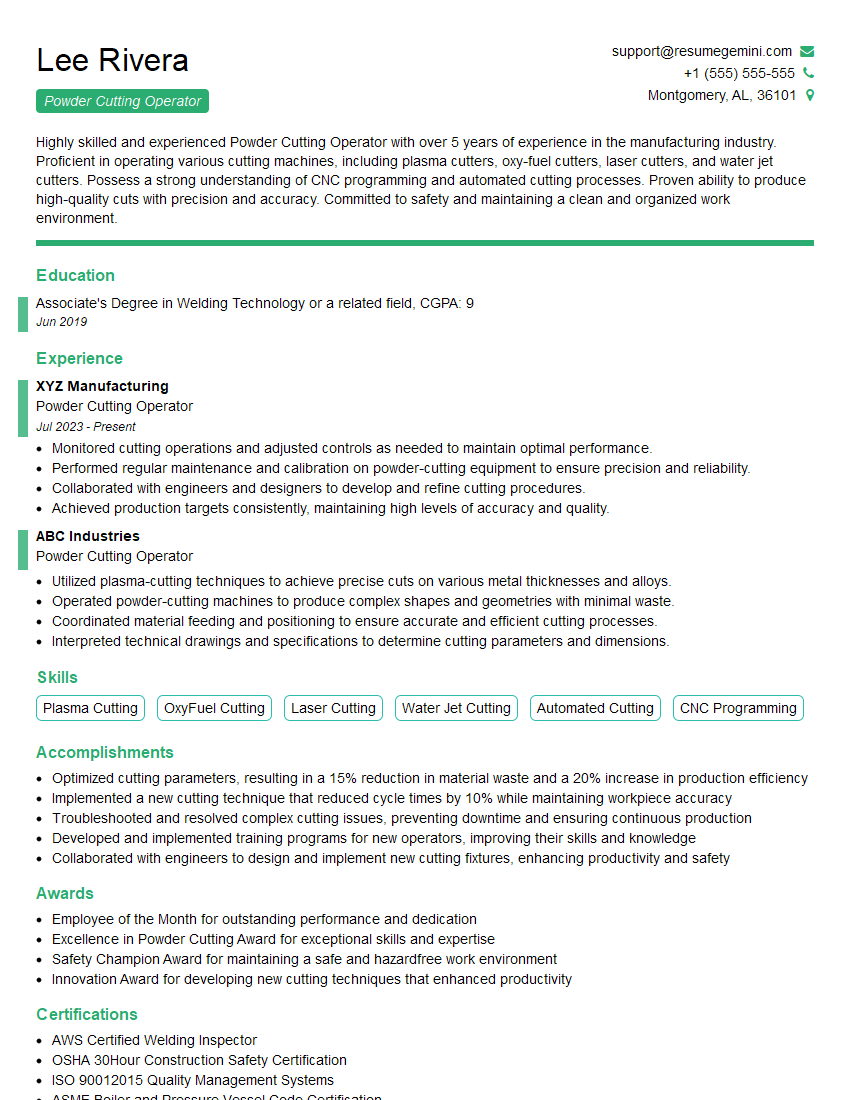

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powder Cutting Operator

1. What are the key responsibilities of a Powder Cutting Operator?

As a Powder Cutting Operator, my primary responsibilities include:

- Operating and maintaining plasma cutting machines

- Interpreting blueprints and technical drawings

- Cutting and shaping metal components according to specifications

- Ensuring the accuracy and quality of cut pieces

- Maintaining a safe and clean work environment

2. Explain the different types of plasma cutting processes.

Thermal Plasma Cutting

- Uses a high-temperature plasma arc to melt and cut metal

- Suitable for thicker materials

Water-Injected Plasma Cutting

- Injects water into the plasma arc to improve cut quality

- Reduces slag formation and produces smooth edges

Transferred Arc Plasma Cutting

- Creates an electrical connection between the plasma arc and the workpiece

- Provides higher cutting speeds and accuracy

3. Describe the safety precautions that must be taken when operating a plasma cutting machine.

To ensure safety, I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring proper grounding of the machine

- Maintaining a clean and well-ventilated work area

- Inspecting the machine before each use

- Following established operating procedures

4. What methods do you use to ensure the accuracy of plasma cuts?

To achieve precise cuts, I employ the following techniques:

- Using sharp and calibrated cutting tips

- Setting the correct cutting parameters (amperage, voltage, etc.)

- Stabilizing the workpiece to prevent movement during cutting

- Monitoring the cutting process to adjust parameters as needed

- Performing regular machine maintenance and calibration

5. What are the common troubleshooting steps you take when encountering issues with plasma cutting equipment?

When facing equipment issues, I follow a systematic approach:

- Identifying the issue (e.g., poor cut quality, machine malfunction)

- Checking for loose connections or damaged components

- Consulting the manufacturer’s manual for troubleshooting guidance

- Inspecting cutting tips and nozzles for wear or damage

- Resetting the machine or adjusting cutting parameters

6. Describe the different materials that can be cut using a plasma cutting machine.

Plasma cutting is commonly used to cut a wide range of materials, including:

- Carbon steel

- Stainless steel

- Aluminum

- Copper

- Brass

7. Explain the process of creating a CNC (Computer Numerical Control) plasma cutting program.

To create a CNC plasma cutting program, I typically follow these steps:

- Converting the CAD drawing of the desired part into a CNC code

- Using a CAM (Computer-Aided Manufacturing) software to generate the cutting path

- Transferring the CNC code to the plasma cutting machine

- Setting up the machine parameters based on the material and cut quality requirements

- Running the program and monitoring the cutting process

8. Describe the methods you use to minimize dross formation during plasma cutting.

To reduce dross formation, I employ techniques such as:

- Using water-injected plasma cutting to reduce slag adhesion

- Optimizing cutting parameters (e.g., amperage, speed, gas flow)

- Using the correct cutting tip size and height

- Maintaining a clean work surface to prevent contamination

- Minimizing dwell time at the start and end of cuts

9. Explain how you maintain and calibrate a plasma cutting machine.

Regular maintenance and calibration are crucial:

- Cleaning and inspecting the machine regularly

- Checking and calibrating the alignment of the cutting head

- Replacing worn or damaged components

- Performing electrical and pressure tests

- Using reference materials to ensure cutting accuracy

10. Describe your experience in reading and interpreting engineering drawings.

I possess strong skills in reading and interpreting engineering drawings:

- Understanding different types of drawings (e.g., orthographic, isometric)

- Identifying dimensions, tolerances, and symbols

- Visualizing the three-dimensional form of the part

- Extracting critical information to program the plasma cutter

- Making adjustments to the cutting process based on the drawing requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powder Cutting Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powder Cutting Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Powder Cutting Operators are skilled professionals who use specialized equipment to cut metal objects. Their primary role is to ensure precision cutting and adherence to specified dimensions while maintaining safety standards.

1. Plasma Cutting

Plasma cutting involves using a high-temperature plasma gas to melt and cut metal. Powder Cutting Operators must:

- Set up and operate plasma cutting equipment

- Select and install the appropriate nozzles and electrodes

- Determine cutting parameters based on material thickness and type

- Monitor and adjust cutting speed, gas flow, and power settings

2. Laser Cutting

Laser cutting uses a highly focused laser beam to vaporize and cut metal. Powder Cutting Operators must:

- Operate and maintain laser cutting machines

- Program cutting paths using CAD software

- Select and adjust laser power, wavelength, and cutting speed

- Monitor cutting process and ensure accuracy and consistency

3. Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through various materials. Powder Cutting Operators must:

- Operate and adjust waterjet cutting systems

- Select and install appropriate nozzles and cutting heads

- Monitor water pressure, abrasive flow rate, and cutting speed

- Ensure the efficient removal of waste material from the cutting zone

4. Safety Protocols

Powder Cutting Operators must prioritize safety while performing their duties. They must:

- Wear appropriate safety gear, including respirators, gloves, and eye protection

- Follow established safety procedures and guidelines

- Inspect equipment regularly and report any potential hazards

- Maintain a clean and organized work area

Interview Tips

To ace an interview for a Powder Cutting Operator position, candidates should keep the following tips in mind:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s background, products, and industry trends. This will help you better understand the role and company culture.

2. Highlight Relevant Experience and Skills

Emphasize your experience in powder cutting techniques, especially in the specific methods used by the company. Showcase your proficiency in operating and maintaining cutting equipment.

3. Prepare for Technical Questions

Be prepared to answer questions about different cutting processes, including plasma, laser, and waterjet cutting. Discuss your understanding of cutting parameters and how you optimize them for different materials.

4. Emphasize Safety Awareness

Safety is paramount in powder cutting. Highlight your commitment to following safety protocols, wearing appropriate gear, and maintaining a safe work environment.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer. This demonstrates your engagement, interest, and desire to learn more about the position and company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powder Cutting Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!