Are you gearing up for an interview for a Power Shear Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Power Shear Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

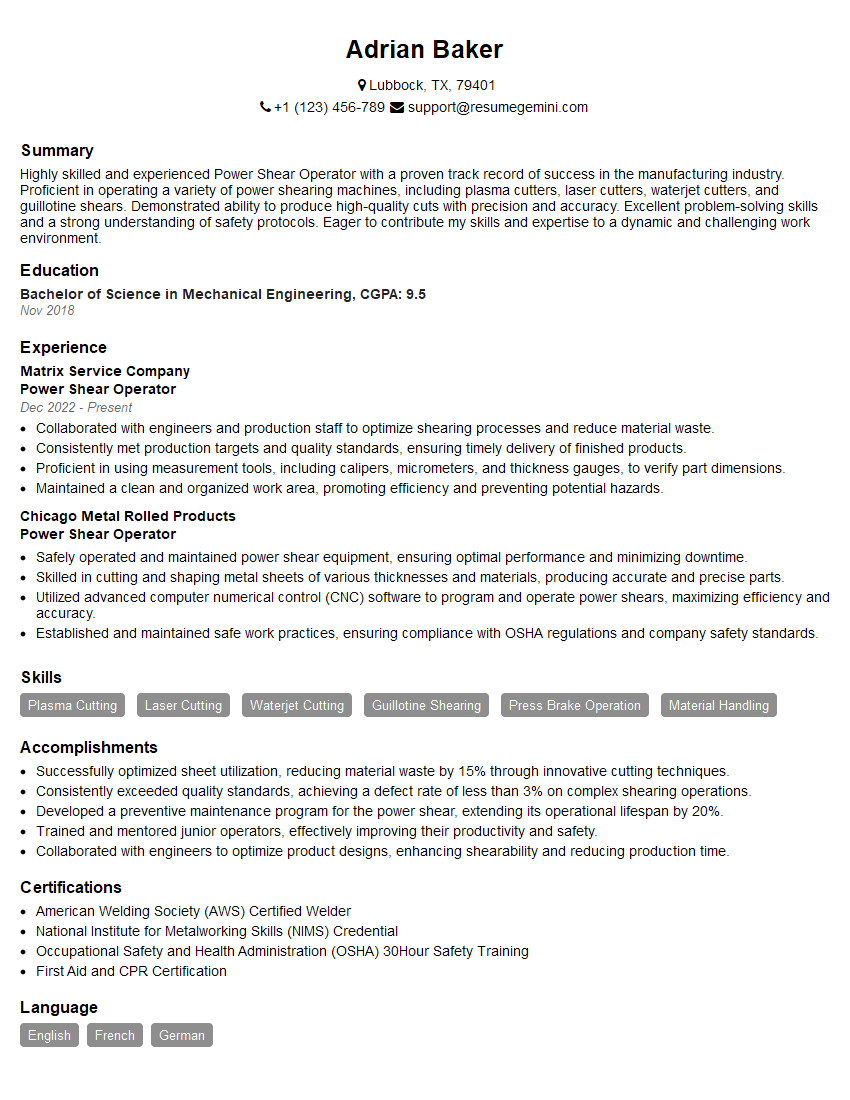

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Shear Operator

1. Tell me about your experience operating power shears?

I have operated power shears for the past five years in a high-volume manufacturing environment. I am proficient in using a variety of power shears, including guillotine shears, rotary shears, and laser shears.

2. What are the safety precautions that you take when operating power shears?

Proper Training

- Always receive proper training before operating power shears.

- Read and understand the operator’s manual.

Guarding

- Make sure all guards are in place and functioning properly.

- Never remove or disable guards.

Personal Protective Equipment

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

Material Handling

- Only cut materials that are the correct size and shape for the shear.

- Make sure the material is properly supported before cutting.

Electrical Safety

- Make sure the shear is properly grounded.

- Do not operate the shear if there are any electrical problems.

3. How do you maintain power shears?

I perform daily, weekly, and monthly maintenance on power shears to keep them in good working condition. Daily maintenance includes cleaning the shear, checking the oil level, and inspecting the blades for wear and tear. Weekly maintenance includes lubricating the shear and checking the electrical connections. Monthly maintenance includes replacing the blades and performing a more thorough inspection of the shear.

4. What are the different types of materials that can be cut with power shears?

Power shears can cut a variety of materials, including metal, plastic, rubber, and fabric. The type of material that can be cut depends on the type of shear and the thickness of the material.

5. What are the different types of cuts that can be made with power shears?

Power shears can make a variety of cuts, including straight cuts, angled cuts, and curved cuts. The type of cut that can be made depends on the type of shear and the skill of the operator.

6. What are the quality standards that you follow when operating power shears?

I follow the quality standards that are set by my employer. These standards include the accuracy of the cuts, the finish of the cuts, and the overall quality of the product.

7. How do you troubleshoot problems with power shears?

I troubleshoot problems with power shears by following a logical process. I first identify the problem and then I try to find the root cause. Once I have found the root cause, I can then develop a solution to the problem.

8. What are the most common problems that you encounter when operating power shears?

The most common problems that I encounter when operating power shears are dull blades, misaligned blades, and electrical problems.

9. What are the different types of power shears?

There are three main types of power shears: guillotine shears, rotary shears, and laser shears. Guillotine shears use a blade that moves up and down to cut the material. Rotary shears use a blade that rotates to cut the material. Laser shears use a laser to cut the material.

10. What are the advantages and disadvantages of using power shears?

Advantages

- Power shears are fast and efficient.

- Power shears can cut a variety of materials.

- Power shears can make precise cuts.

Disadvantages

- Power shears can be dangerous if they are not used properly.

- Power shears can be expensive to purchase and maintain.

- Power shears can be noisy.

11. What is the most important thing to keep in mind when operating power shears?

The most important thing to keep in mind when operating power shears is safety. Power shears can be dangerous if they are not used properly. Always follow the manufacturer’s instructions and wear appropriate safety gear.

12. What are some tips for operating power shears safely?

- Always wear safety glasses and gloves.

- Keep your hands away from the blade.

- Never operate the shear if it is not properly grounded.

- Make sure the material is properly supported before cutting.

- Never cut material that is too thick for the shear.

13. What is the best way to clean and maintain power shears?

The best way to clean and maintain power shears is to follow the manufacturer’s instructions. In general, you should clean the shear after each use and lubricate it regularly.

14. What are the signs that power shears need to be repaired?

- The shear is not cutting properly.

- The shear is making strange noises.

- The shear is leaking oil or hydraulic fluid.

- The shear is vibrating excessively.

15. What are some of the common mistakes that people make when operating power shears?

- Not wearing proper safety gear.

- Operating the shear without proper training.

- Cutting material that is too thick for the shear.

- Not supporting the material properly before cutting.

- Not cleaning and maintaining the shear properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Shear Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Shear Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Shear Operators are responsible for using power shears to cut and shape metal sheets, plates, and other materials. They work in a variety of industries, including manufacturing, construction, and shipbuilding.

1. Cutting Metal

Power Shear Operators use power shears to cut metal sheets and plates into specific shapes and sizes. They must be able to read and interpret blueprints and drawings, and they must be able to set up and operate the power shear correctly to ensure that the cuts are made accurately and safely.

- – Set up and operate power shears to cut metal sheets and plates into specified shapes and sizes.

- – Read and interpret blueprints and drawings to ensure that cuts are made accurately.

- – Inspect cut metal for accuracy and quality.

2. Shaping Metal

Power Shear Operators also use power shears to shape metal sheets and plates. They can use the power shear to bend, roll, or form metal into various shapes. They must be able to work with different types of metal and they must be able to use the power shear to create precise shapes.

- – Use power shears to shape metal sheets and plates by bending, rolling, or forming.

- – Work with different types of metal, including steel, aluminum, and stainless steel.

- – Create precise shapes using the power shear.

3. Maintaining Equipment

Power Shear Operators are also responsible for maintaining the power shear equipment. They must be able to troubleshoot and repair problems, and they must be able to keep the equipment clean and in good working condition.

- – Maintain power shear equipment by troubleshooting and repairing problems.

- – Keep equipment clean and in good working condition.

4. Safety

Power Shear Operators must always follow safety procedures when operating the power shear. They must wear appropriate safety gear, and they must be aware of the potential hazards of the equipment. They must also be able to work safely with other workers in the area.

- – Follow safety procedures when operating the power shear.

- – Wear appropriate safety gear.

- – Be aware of the potential hazards of the equipment.

- – Work safely with other workers in the area.

Interview Tips

Interviewing for a Power Shear Operator position can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you learn more about the company’s culture, values, and products or services. You can also use this information to tailor your answers to the interviewer’s questions.

- – Visit the company’s website.

- – Read articles about the company in trade publications.

- – Talk to people who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- – Write down your answers to common interview questions.

- – Practice saying your answers out loud.

- – Get feedback from a friend or family member.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Power Shear Operator. Be prepared to talk about your experience operating different types of power shears, and be able to provide examples of your work.

- – Highlight your experience operating different types of power shears.

- – Provide examples of your work, such as projects you have completed.

- – Be prepared to talk about your safety record.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- – Wear a suit or business casual attire.

- – Make sure your clothes are clean and pressed.

- – Avoid wearing strong perfumes or colognes.

5. Be Punctual

It is important to be punctual for your interview. This shows the interviewer that you are respectful of their time. If you are running late, be sure to call or email the interviewer to let them know.

- – Plan your route to the interview in advance.

- – Leave yourself plenty of time to get to the interview.

- – If you are running late, call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Shear Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!