Feeling lost in a sea of interview questions? Landed that dream interview for Precipitator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Precipitator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

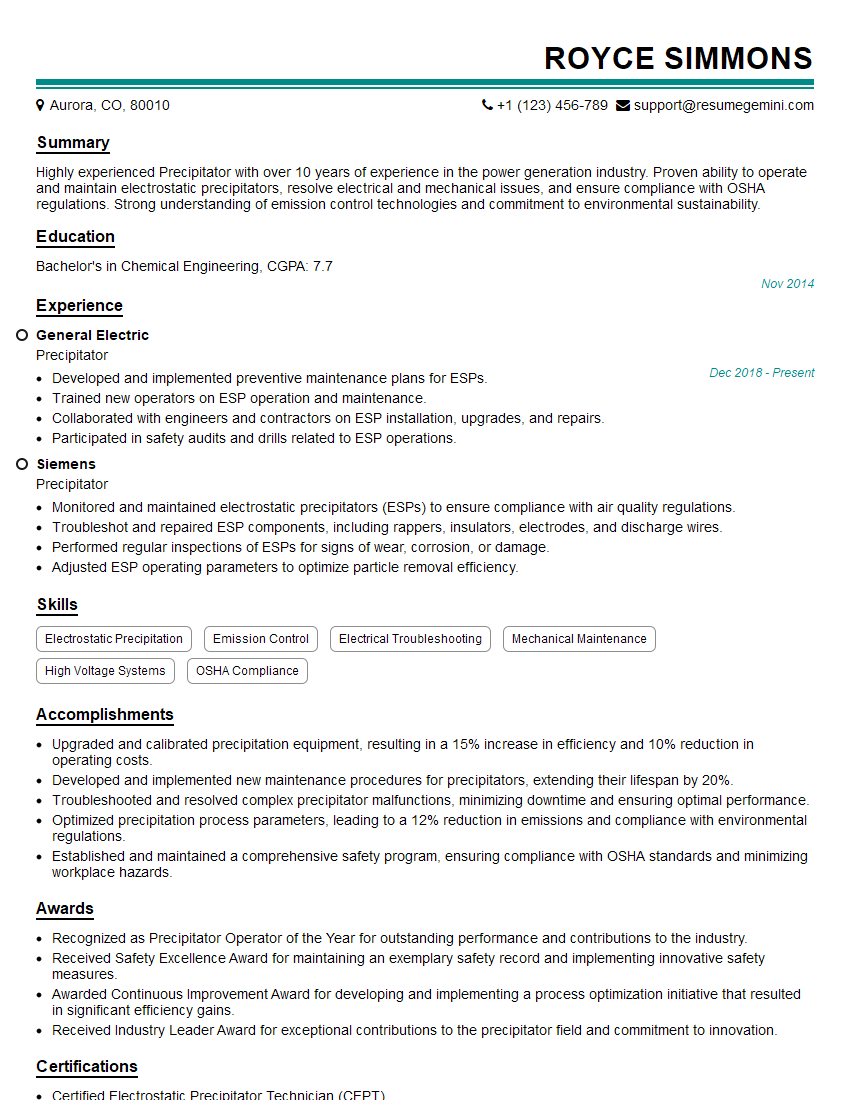

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precipitator

1. Describe the principles of electrostatic precipitators (ESPs). How is particulate matter removed from a gas stream using ESPs?

ESPs use high voltage to create an electric field, which attracts and captures small particles in the air. When the particles collect on the ESP’s collection plates, they are removed from the air stream.

2. What are the different types of ESPs and their advantages and disadvantages?

There are three common types of ESPs: single-stage, two-stage, and wet ESPs. Single-stage ESPs are the most common type, and they are typically used for small to medium-sized applications. Two-stage ESPs are more efficient than single-stage ESPs, and they are typically used for larger applications. Wet ESPs are the most efficient type of ESP, but they are also the most expensive.

3. What are the key design considerations for ESPs?

The key design considerations for ESPs include the gas flow rate, the particle size distribution, and the desired collection efficiency. The gas flow rate determines the size of the ESP, and the particle size distribution determines the type of ESP that is required. The desired collection efficiency determines the number of collection plates that are required.

4. How do you calculate the collection efficiency of an ESP?

The collection efficiency of an ESP is calculated using the following equation: η = 1 – e^(-kQ / A) Where: η is the collection efficiency k is the corona discharge constant Q is the gas flow rate A is the area of the collection plates

5. What are the common problems that can occur with ESPs and how can they be addressed?

The common problems that can occur with ESPs include: * Electrical problems, such as arcing or corona discharge, can be addressed by inspecting the ESP and repairing or replacing any damaged components. * Mechanical problems, such as broken collection plates or damaged insulators, can be addressed by inspecting the ESP and repairing or replacing any damaged components. * Process problems, such as high particle loading or changes in the gas flow rate, can be addressed by adjusting the ESP’s operating parameters.

6. What are the latest advancements in ESP technology?

The latest advancements in ESP technology include: * The development of new materials for collection plates, such as nanofibers and carbon nanotubes, that have a higher collection efficiency. * The development of new electrode designs, such as pulsed electrodes and segmented electrodes, that improve the ESP’s performance. * The development of new control systems, such as artificial intelligence and machine learning, that optimize the ESP’s operation.

7. What is the future of ESP technology?

The future of ESP technology is bright. ESPs are a cost-effective and efficient way to remove particulate matter from a gas stream, and they are becoming increasingly important as the world becomes more focused on environmental protection. The latest advancements in ESP technology are making ESPs even more efficient and reliable, and they are expected to continue to play a major role in air pollution control in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precipitator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precipitator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precipitators play a vital role in environmental protection by removing particulate matter from industrial emissions. As a Precipitator, your key job responsibilities will include:

1. Installation and Commissioning

Collaborating with project engineers to install and commission precipitators, ensuring optimal performance and compliance with environmental regulations.

2. Troubleshooting and Maintenance

Identifying and resolving equipment malfunctions, performing routine maintenance and repairs, and keeping detailed records of maintenance activities.

3. Monitoring and Evaluation

Monitoring precipitator performance, evaluating efficiency, and recommending improvements to optimize air quality.

4. Safety Compliance

Adhering to safety protocols, using appropriate personal protective equipment, and maintaining a safe work environment.

Interview Tips

To prepare for your Precipitator interview, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s environmental commitment and the specific industry in which they operate. This will help you understand their needs and demonstrate your knowledge of the field.

2. Highlight Relevant Experience

Emphasize your previous experience in precipitator installation, maintenance, or troubleshooting. Provide specific examples to showcase your technical abilities and problem-solving skills.

3. Prepare for Technical Questions

Be prepared to answer questions on precipitator design, operation, and maintenance procedures. Review common troubleshooting scenarios and demonstrate your knowledge of industry standards.

4. Showcase Your Safety Knowledge

Highlight your understanding of safety regulations and your commitment to maintaining a safe work environment. Discuss your experience with hazard identification, risk assessment, and emergency response procedures.

5. Practice Your Communication Skills

Communicating effectively is crucial. Practice answering interview questions clearly and concisely, using specific examples to support your responses. Be prepared to discuss your teamwork and problem-solving abilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Precipitator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Precipitator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.